Cellar Summaries

This page reviews our cellar activities for then thirteen vintages cellared to date. Before 2017 we used a spreadsheet to track the sensory qualities, the laboratory results, and the actions taken approximately every 1-2 months as we monitored each vessel. In 2017 we switched to a relational database. This page shows the screenshots of the summary tab in the Cellar Batch Reviews for each vintage (note, the commentaries in the database are not yet complete). The laboratory measurements showed up only later as we became more diligent with chemical analysis and recording. In summary:

2009: with the help of an experienced nose & palate (Aran Healy), we took a minimalist approach (only two rackings) and recorded very little of the few lab tests taken.

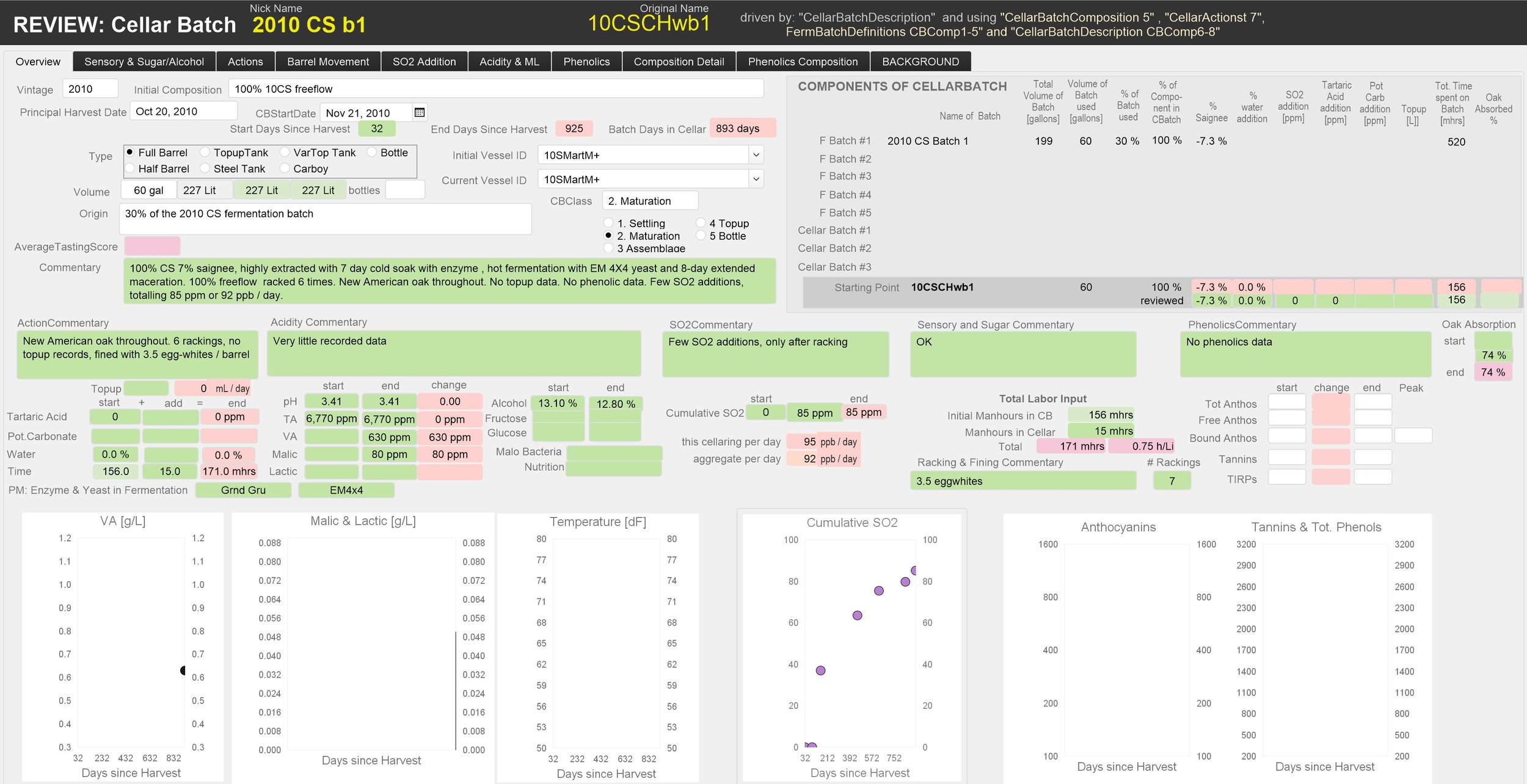

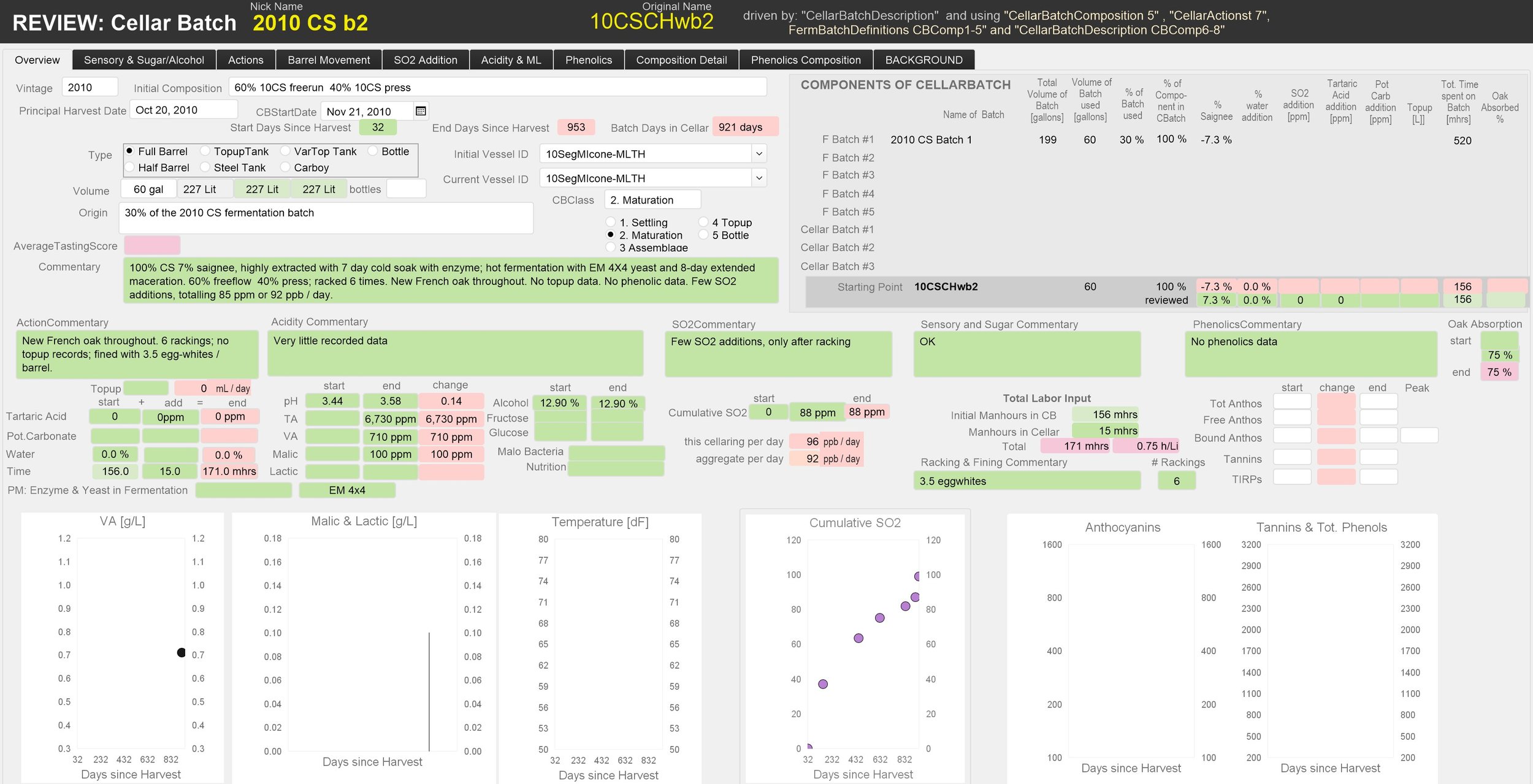

2010: we changed to regular racking to soften the tannins through more oxidation; the young wine was over-extracted in fermentation. We continued to rely on Aran's tasting experience for monitoring and only recorded very few lab tests.

2011: we were challenged by a poor harvest and the departure of the nose. I failed to rack and monitor the top-up wines properly and introduced wine faults that may have affected the barrels. We bottled a mix of 66% 2011 Cabernet with 33% 2012 Merlot.

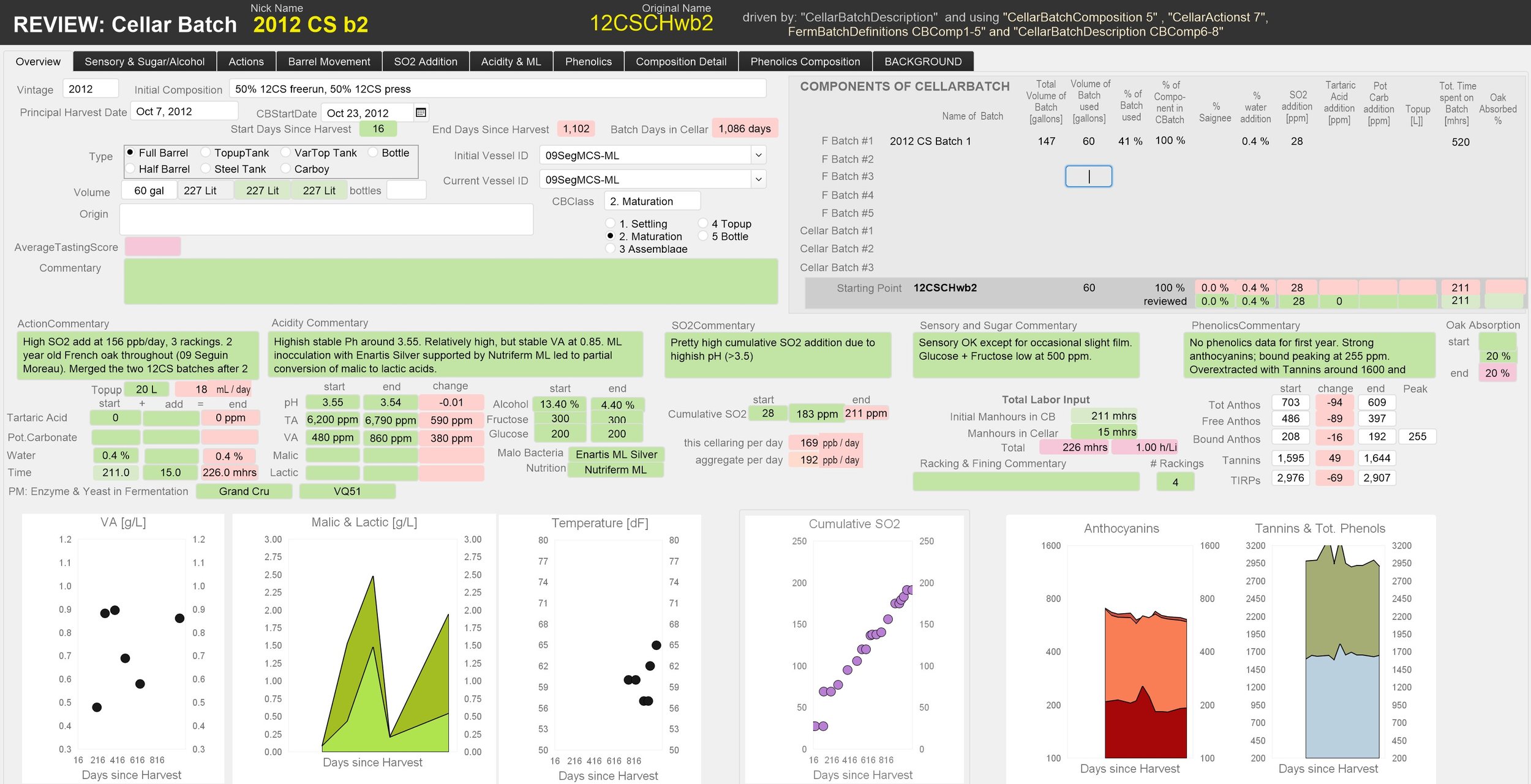

2012: the harvest was excellent, but our cellaring continued to be challenged by the lack of a professional "nose," poor laboratory analysis/recording, and faulty racking practices on the top-up wines. We combined all top-up wines and struggled with the resulting cross-contamination.

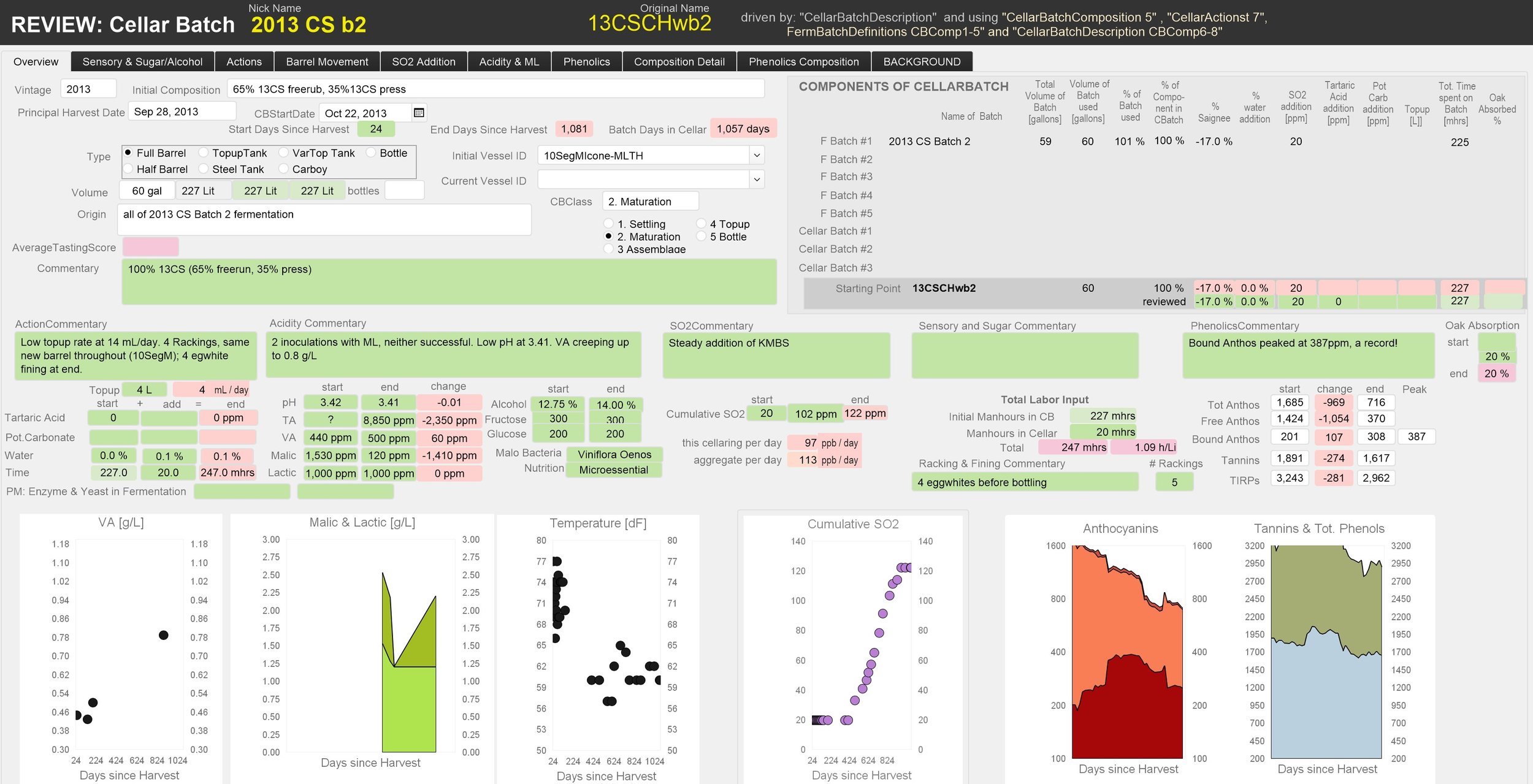

2013: a great harvest combined with corrected barrelling practices. We welcomed a new nose (David Fenyvesi in late 2012) and significantly improved laboratory practices. There is hope. We decided to extend barrel aging for this vintage from our standard three to four years.

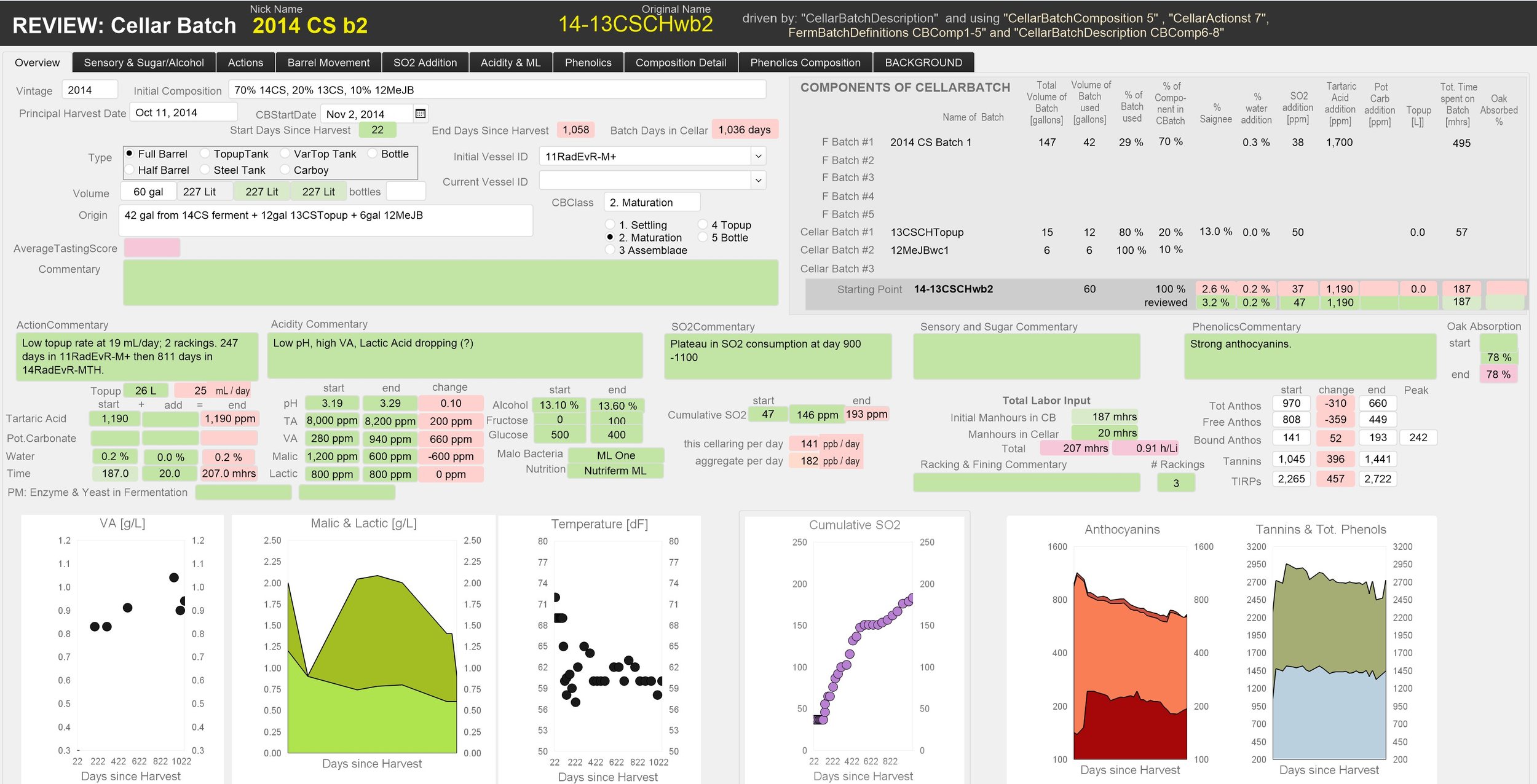

2014: the harvest was good in quality but 30% less in volume, so we had to add 12 gallons of 2012 CSV topup wine and 6 gallons of Jim Barth's Merlot to fill the second barrel. Acidity was low, so we added tartaric acid, but it turned out too much, and we struggled through barrel aging until we cold-stabilized.

2015: the harvest was poor in quality and volume. We could fill one barrel only by adding 8 gallons of the 2012CSV blend to be bottled. Our cellar management was equally poor. We added too much Tartaric Acid to reduce the pH and then had to compensate by adding Potassium Carbonate to bring the pH back up. Significant additions of SO2 did not contain contamination as Volatile Acidity increased to over 1100 ppm.

2016: the harvest was plentiful and included, for the first time, the Merlot, Petit Verdot, and Cab Franc from the upper field, but phenolics were poor. We free-flowed into three oak barrels. We successfully fought barrel contaminations with fining and cross-flow filtration. We bottled with 3.4pH, 15%+ alcohol, 880 bottles.

2017: the harvest was poor both in volume and quality. We free-flowed into one full and one half-barrel. This is the last vintage in which we used topup wines from previous years, a probable source of contaminations which we fought with fining and reverse osmosis filtering.

2018: the harvest was excellent in volume and quality. We inoculated for malolactic fermentation and used less SO2. Cellaring was mostly in neutral barrels. We added Tartaric Acid to reduce the pH. All topup wine was from the same vintage kept in steel tanks for three years. We produced 280 bottles of pure Cab and 580 bottles of Bordeau blend.

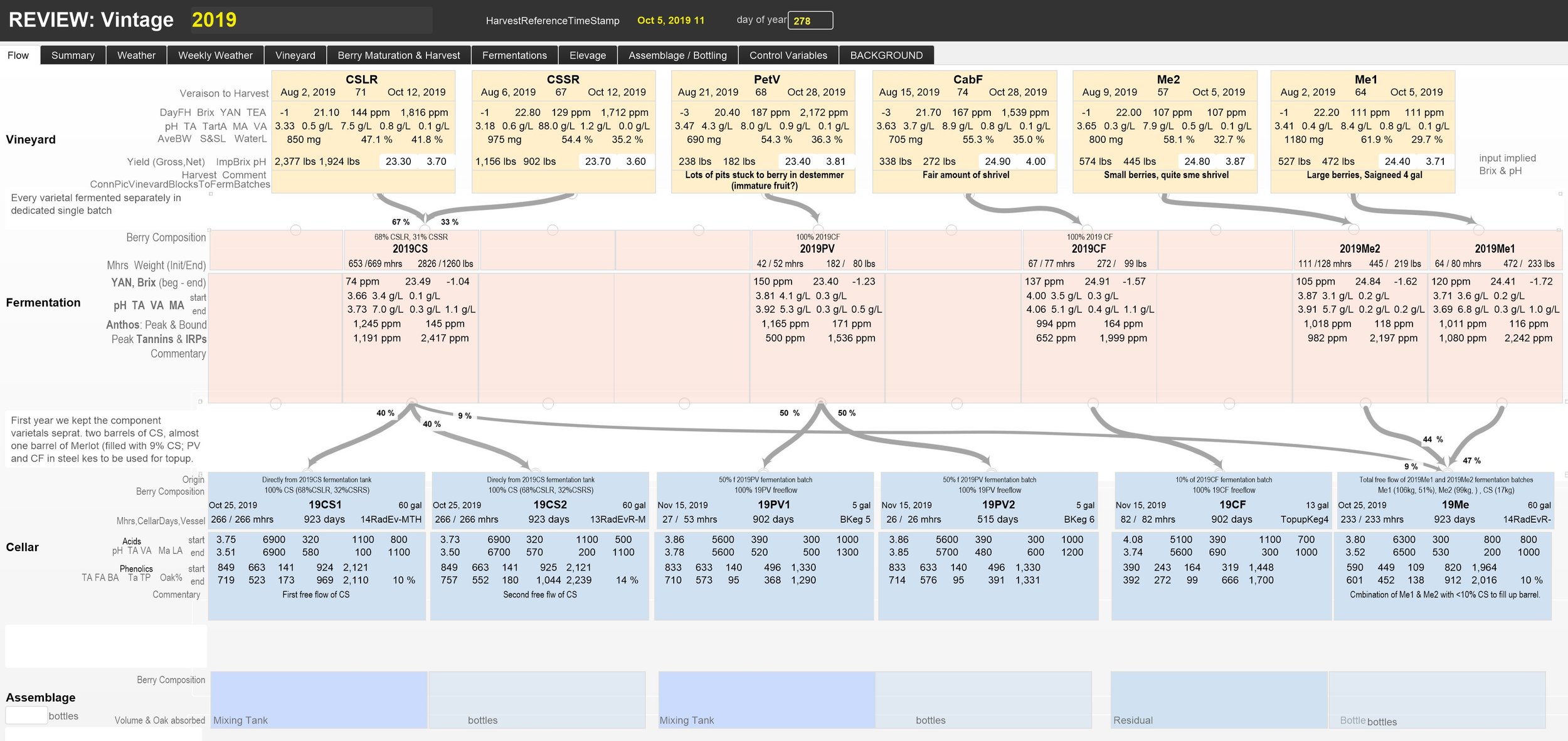

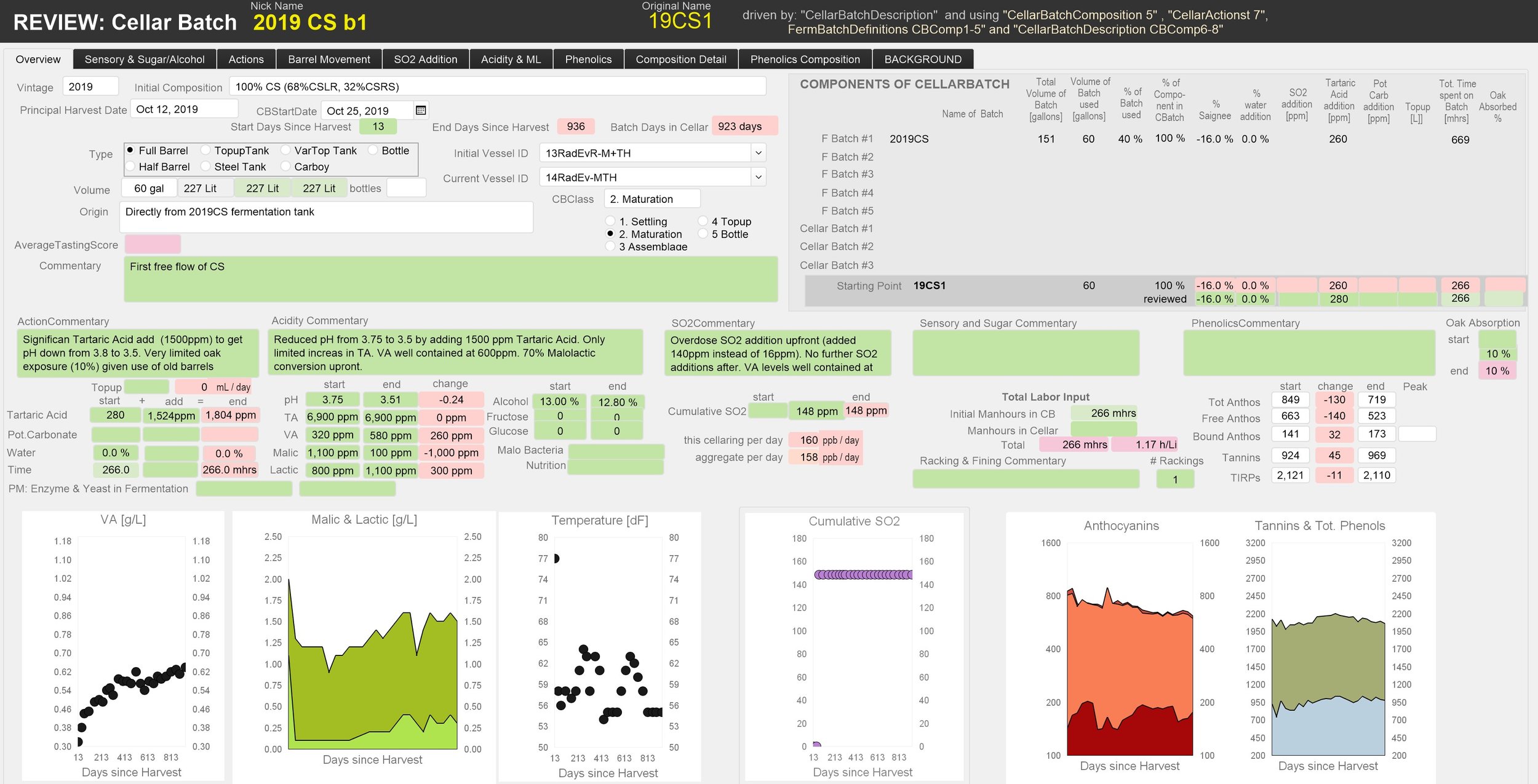

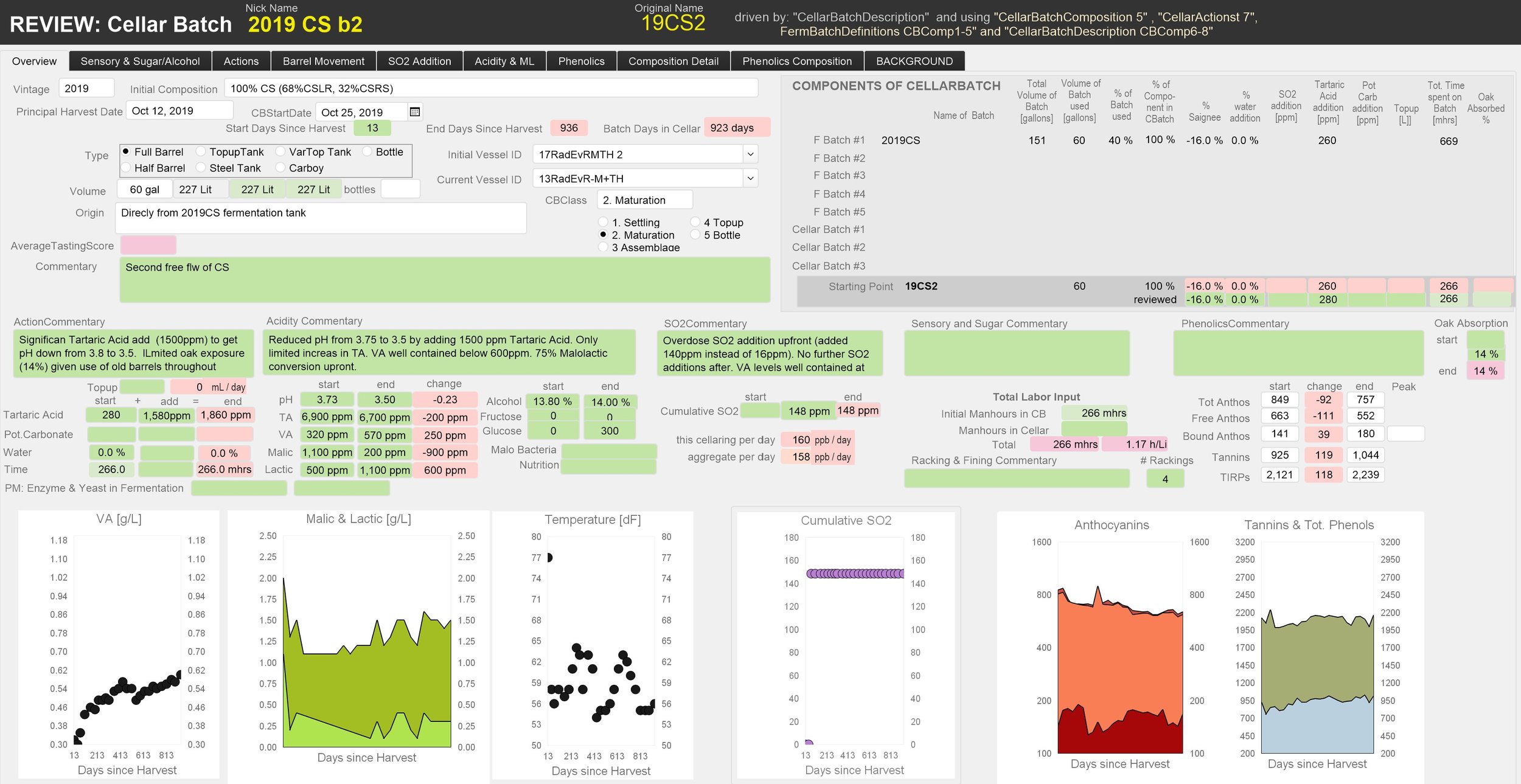

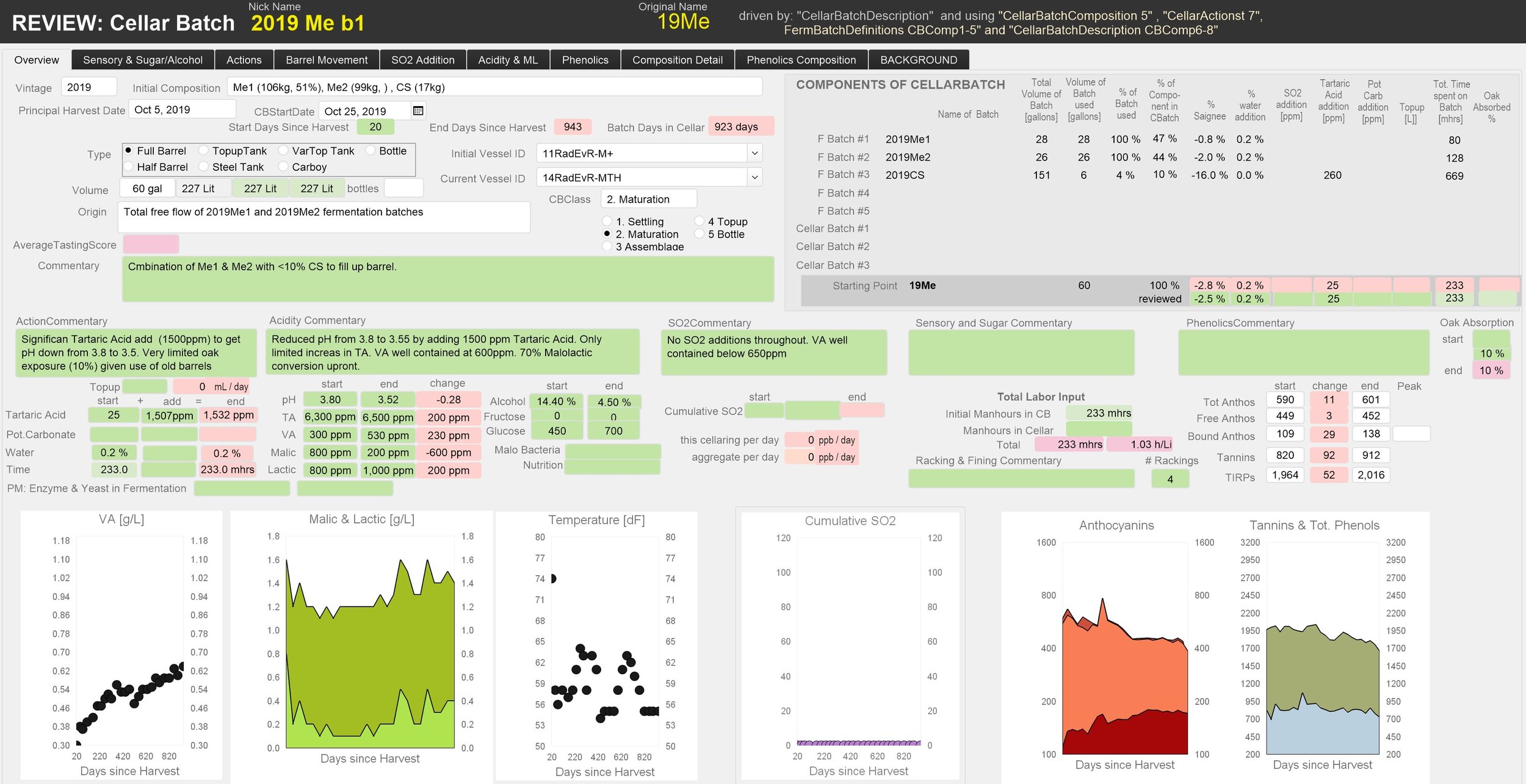

2019: a rainy winter and hot summer produced the largest harvest to date with clean fruit but skewed maturation: 23.7 Brix, 3.7+ pH, and lack of nitrogen. Malolactic fermentation completed naturally. We started cleaning barrels with hot steam. Improved sanitation reduced contaminations. More to come

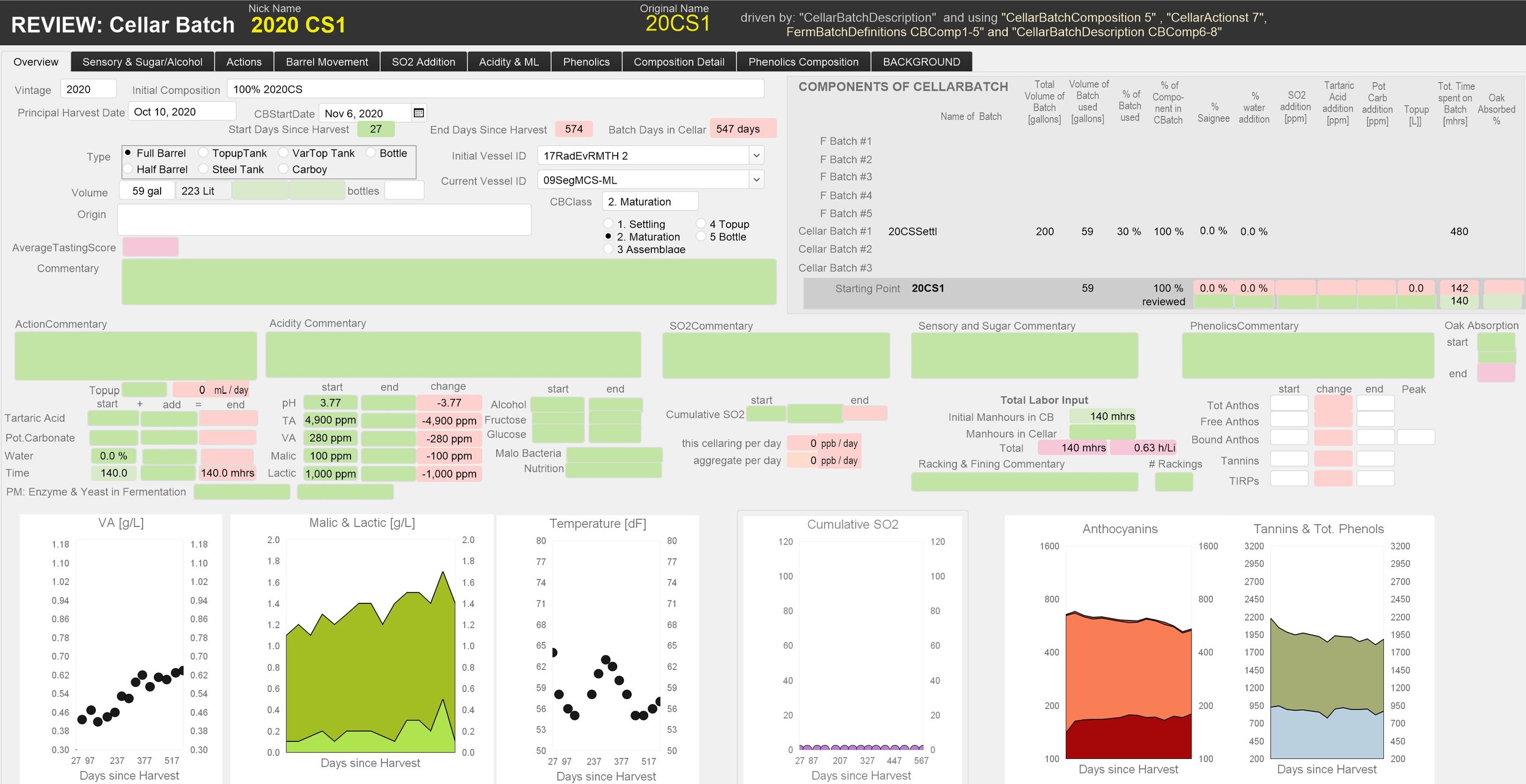

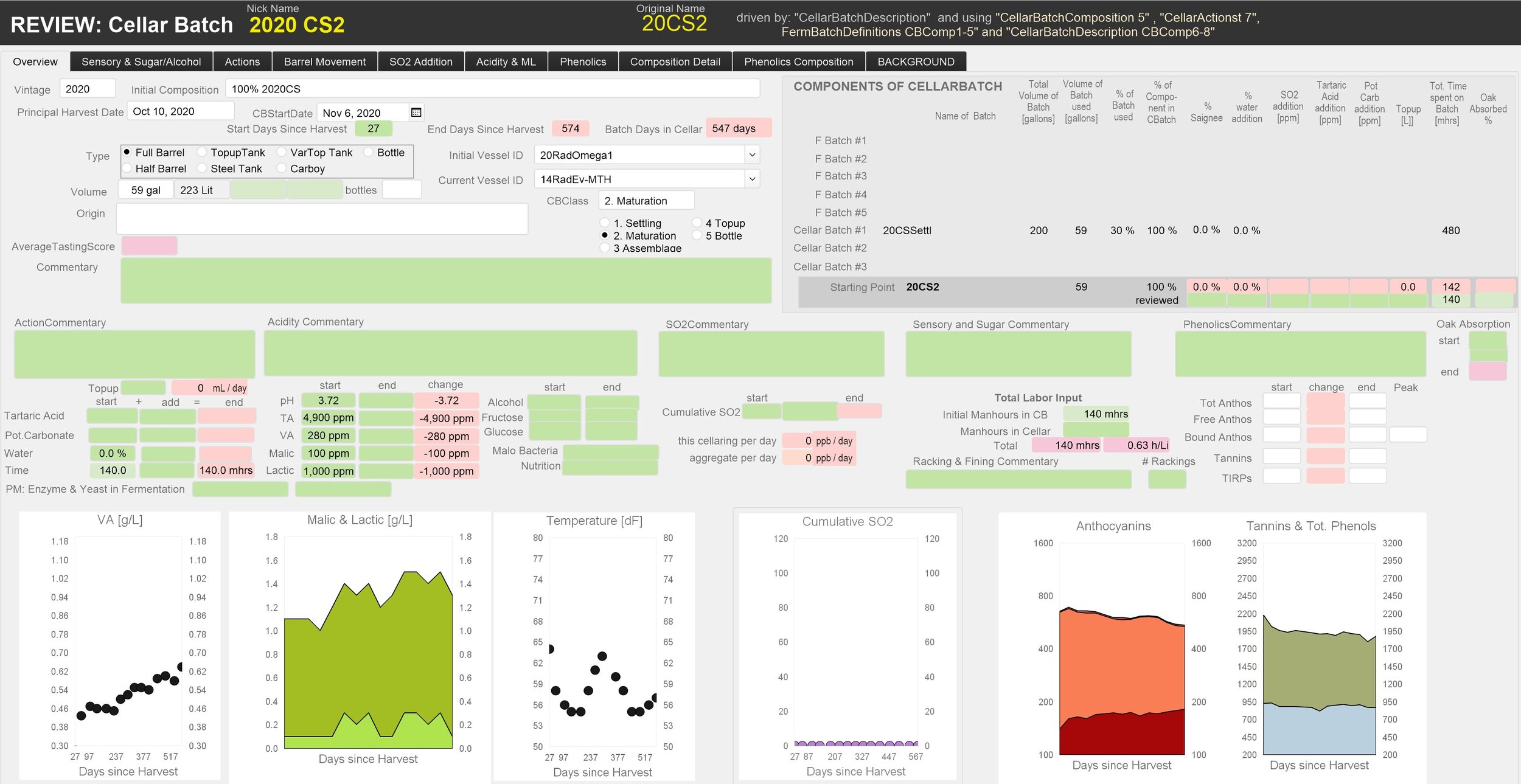

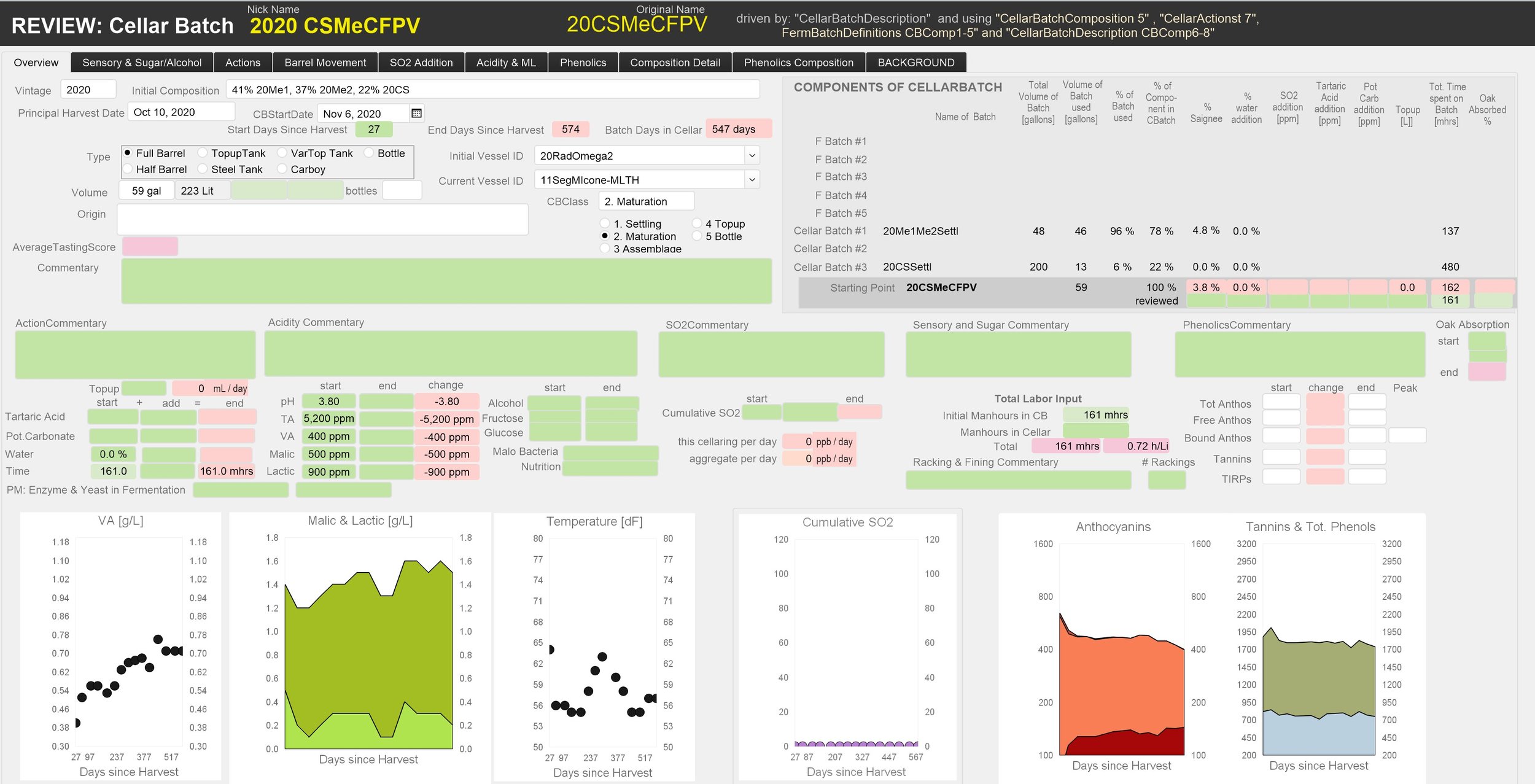

2020: the weather was dry but with many heat spikes in a hot summer. Harvest volume was down, and quality reduced: pH averaged 3.75 at Brix of 23.5. Cellaring was in 2 barrels for pure Cab and 1 barrel for Bordeau blend with dedicated topup tanks from the same vintage. Malolactic fermentation completed naturally. More to come.

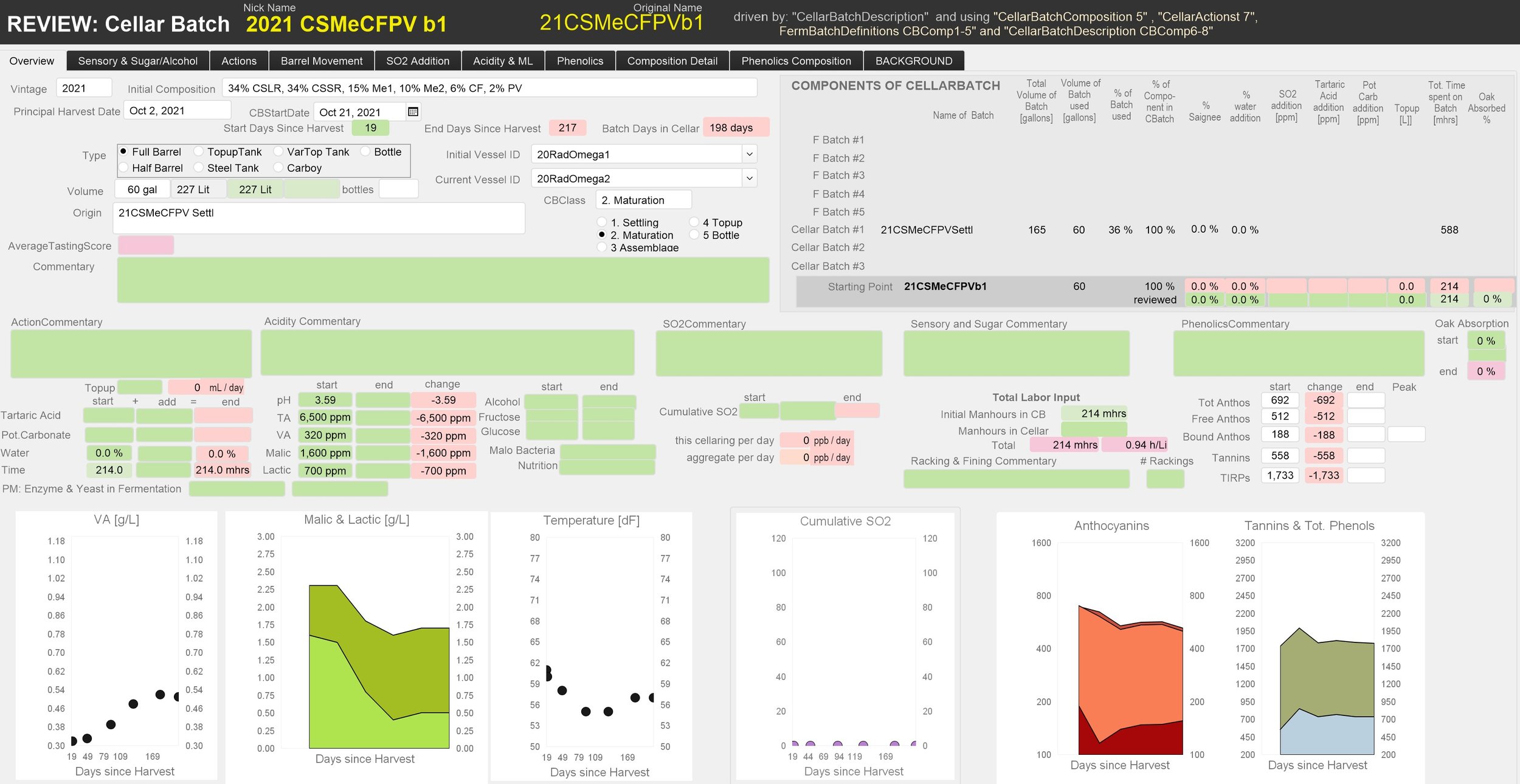

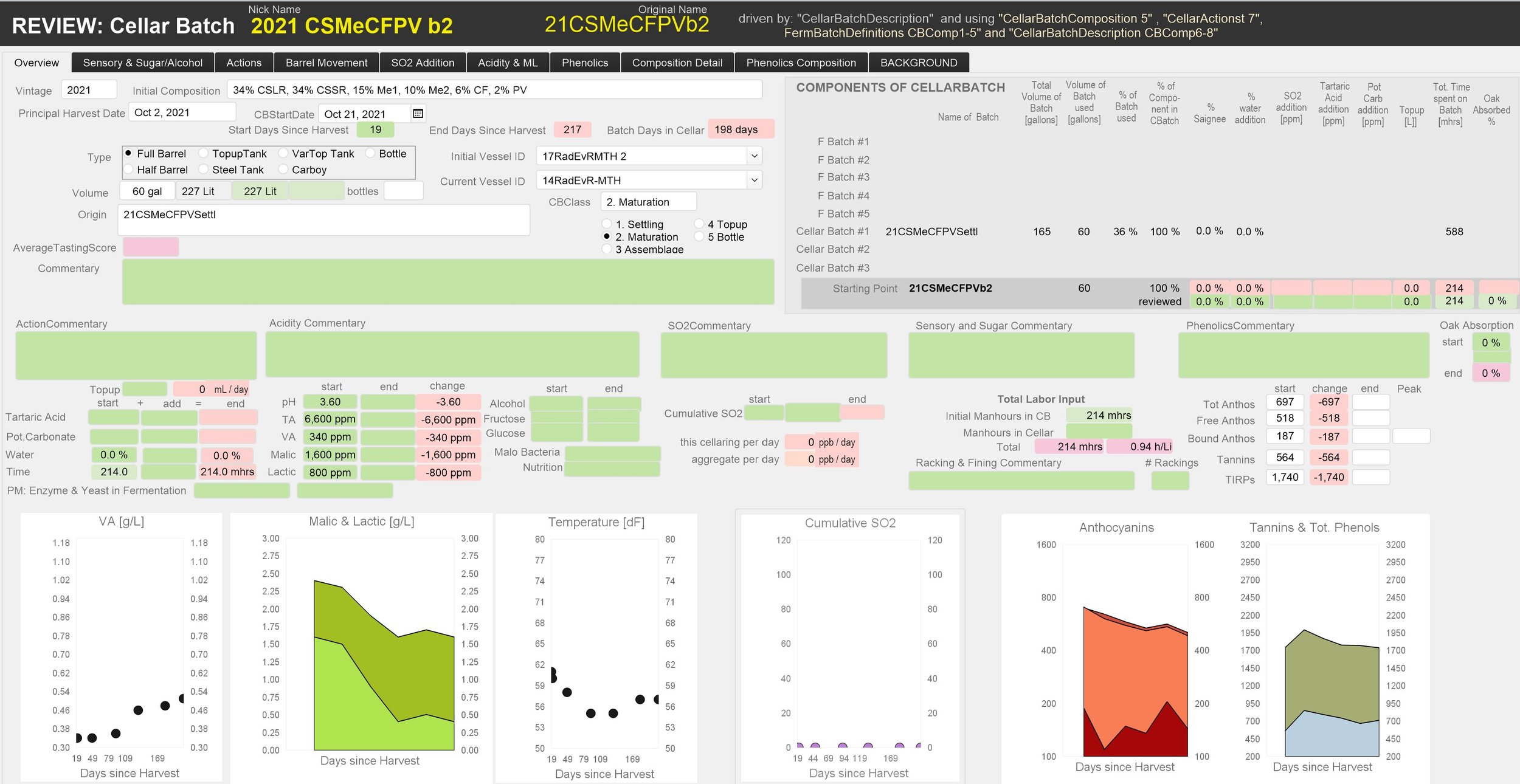

2021: the weather was miserable: a dry winter followed by a hot summer and spikes. Harvest volume was down 50% from the 2018 peak quality was OK at 3.4 pH and 21.5 Brix, but lack of nitrogen required a large addition of nutrients for fermentation. We cellared in two barrels of Bordeau blends with identical topup wine. More to come

The following paragraphs describe each vintage in more detail.

2009 Vintage

2009 was our first year of wine-making and cellaring. We continued the minimalist wine-making approach into barrelling. The process remained very basic: On completing Malolactic fermentation in the barrels, we added a 25ppm dose of sulfur and maintained a level above eight ppm, checking quarterly. We racked the barrels only twice, the first time six months after harvest, the second time just before bottling. We took minimal measurements and judged progress mainly by smelling and tasting (mostly Aran Healy's nose and palate). We kept extra wine in a few glass carboys (between 1 and 6 gallons each) and topped up the barrels every 3-6 months.

We used one new French oak barrel (Seguin Moreau Select Cabernet ML), one neutral American barrel (unknown provenance), and a refurbished half-barrel (unknown provenance). We had a recording gap between June 2010 and October 2011 and didn't remember how many times we adjusted SO2 and topped up.

Following are screenshots of the Cellar Batch Reviews for the three 2009 barrels:

After 27 months in the barrel, we decided to bottle in 3 separate batches so we could continue to see the effect the different barrels had on the wine:

Oaked: we mixed the entire contents of the French oak barrel with 30 gallons of the used American barrel and put them into 450 bottles labeled 2009 Oaked.

Unoaked A: we put the remaining 30 gallons of the used American barrel into 150 bottles labeled 2009 Unoaked A

Unoaked B: we put the entire content of the refurbished / neutral half-barrel into 150 bottles labeled Unoaked B.

2010 Vintage

In contrast to 2009, we became far more interventionist: We decided to rack more frequently (every 3 to 6 months) to expose the young wine to more oxygen. We also decided to fine the wine with 3 1/2 egg whites just before bottling. We used a new French oak barrel (Seguin Moreau Icone) and a new American oak barrel (Saint Martin M+) to evaluate the difference in oak.

We mixed the remaining 2009 topup wine with the 45 gallons of press wine from 2010 and kept the lot in a 50-gallon steel tank with a variable top lid. We traded juggling the heavy glass carboys with a steel tank which tended to attract fruit flies and microbial infections at the seal of the variable top lid.

We continued to rely on Aran Healy's nose and palate to judge progress and did not record the few laboratory tests we took other than the SO2 measurements required to calibrate the sulfur additions. The exception was in May 2013 when we brought samples to Fermentation Solutions for a test panel based on their new OenoFoss spectral analysis instrument.

Following are screenshots of the Cellar Batch Reviews for the two 2010 barrels:

After 30 months in the barrel, we decided to mix the wine from the 2 barrels, tame the excessive tannins with an egg-white fining, and bottle in a single lot of 48 cases (570 bottles). The flavor profiles of the French and American oak complemented each other. The wine was over-extracted during fermentation and will take a long time in the bottle to mellow out.

2011 Vintage

2011 was a problematic harvest (low yield, not fully ripened fruit). The challenges kept compounding in the winery as Aran Healy's nose and palate, on which we relied to judge progress, departed in early 2012 (together with Aran himself) and left me struggling without the support of an experienced winemaker for over a year. We used a French Oak barrel (Radoux Blend Evolution R) and set the second barrel (Seguin Moreau Icone), which we had already purchased, aside for next year. We combined the little amount of 2011 excess wine with the leftover 2010 topup wine. After 1 ½ years in the French oak, we racked the wine into an American oak barrel (Saint Martin M+) to cover up the green apple character (pyrazine).

In retrospect, the trouble started when I forgot to rack the topup steel tank in 2012 and did not pick up any fault until July 2013 while using that wine all along to top up the 2011 barrel. We then compounded the problem by adding to it the bulk of the contents of the 2012 topup tank, which had similar issues. As a result, we lost half the topup wine and may have polluted the 2011 barrel.

By February 2014, we concluded that the 2011 Cabernet was not strong enough to stand on its own and decided to mix it with half a barrel of the 2012 Merlot from Bargetto (see next paragraph). The problem with that Merlot was that it did not complete its malolactic fermentation (even after a second inoculation). So we ended up with a weak Bordeau mix (Anthocyanins at 93) with a high level of malic acids. As we store the bottles at 55dF, the risk of a late ML fermentation in the bottle is minimal.

2012 Vintage

2012 was an excellent vintage, both regarding quality and yield. We produced two barrels of Cabernet from our fruit, purchased half a ton of Merlot grapes from Bargetto to yield another barrel, and traded in a carboy of Merlot wine from Jim Barth. The idea behind the Merlot purchases was to get an option for blending down the road. By mid-2013, we had introduced a solid quarterly cellar review process that produced reasonable laboratory figures. We started to benefit from the experienced nose and palate of our new live-in winemaker, David Fenyvesi, and we introduced phenolic analysis in the 3rd quarter.

Merlot: We put the Bargetto Merlot first into a neutral french barrel and changed six months later to a French barrel used for two years (2011 Radoux Evolution R). We only noticed in early 2014 that it never went through malolactic fermentation. We treated it with 225g of potassium bicarbonate to increase the pH to 3.5 and re-inoculated it with Viniflora CH16 bacteria. In the summer of 2014, we used half the barrel to blend with the 2011 Cabernet Sauvignon and moved the rest to a neutral half-barrel. By September 2014, that half-barrel proved to be problematic – the wine developed a foul smell and high Volatile Acidity; so we decided to discard that half-barrel and move the Merlot to a pressurized steel keg and carboys.

Cabernet Sauvignon: We barreled the wine into two French oak barrels, one new leftover from 2011 (Seguin Moreau Icone) and one used previously for the 2009 vintage (Seguin Moreau Select). We merged 24 gallons of topup wine with the remaining 10 gallons of the 2011 topup wine; then, we moved the topup wine from the variable top steel tank into two new pressurized steel topup tanks. Again, we did not check the SO2 levels in the topup tanks, and we missed to rack it for the first nine months. Consequently, we may have polluted one of the two barrels, but the rotten egg smell disappeared after another racking of the barrels and KMBS additions

We merged the two Cabernet barrels with the remaining 15 gallons of the 2012 Barghetto Merlot for bottling. Because by then, we were running out of the top-up wine, we moved 15 gallons of this mix into a pressurized topup tank as 12CSMerCHBargTopup and bottled the rest in 45 cases as 12CSMeCHBargb.

2013 Vintage

2013 was a splendid vintage with good yields and excellent berry quality. This is the first year we tracked the phenolics from the start (see Winery section) and thus better understand their evolution. We used a new French oak barrel (Radoux TR M+) and recycled a 3-year-old French barrel used for two years (2010 Seguin Moreau Icone). We had 20 gallons of extra press wine which we kept in the 200-liter variable-top steel tank. We detected a slight off-nose in the second barrel, which may have resulted from a microbial infection from its prior use. So we racked the wine into a steel barrel while treating the empty barrel with a KMBS solution and sulfur fumigation.

By February 2014, malolactic fermentation had not progressed, so we decided to re-inoculate all wine with Viniflora CH16 while keeping the temperature elevated at ~70dF. By July 2014, we noticed a slight decrease in malic acid and a slow buildup of lactic acid, which gave us hope that malolactic fermentation was restarted, albeit weak. We kept the barrels at close to ~70dF. By late 2014 the malolactic fermentation looked complete.

We found significant film in the 2013 top-up tank in late January 2014, which we scooped out, judging it as dead yeast brought to the surface due to the slight vacuum in the headspace created by sampling. To protect, we added 15 ppm of SO2 as a preventative measure, although malolactic fermentation was incomplete, and we moved the topup wine into a freed-up pressurized steel tank. By April 2014, the 2013 topup wine had developed a strong rotten egg smell, and we decided to treat it with a heavy dose of KMBS and move it aside into carboys; after that, we used the leftover 2012 topup wine for topping up the 2013 vintage. The 2013 topup wine recovered by the end of 2014, and we used it to fill up the second barrel in the 2014 vintage, which was a little short.

The Bound Anthocyanin levels peaked in mid-2015 at slightly over 380 (ppm ME), a record. By late 2015 the wine developed well, except for the relatively high level of Volatile Acidity at 800 ppm.

On September 24, 2016, we bottled 42 cases as 13CSCHb and kept 15 gallons in topup tank 13CSCHTopup

2014 Vintage

The 2014 vintage was average, quality-wise, and poor on volume as we continued to fight the Eutypa infection. We could barely fill the second barrel by adding 12 gallons of the 2012 CSV top-up and 5 gallons of the 2012 Merlot from Jim Barth. This screenshot shows the overall flow

The Malolactic fermentation was again slow, probably a cause of the relatively high acidity. The more diligent cellaring routines showed promising results: we had hardly any microbial infections in either barrel compared to previous vintages. After nine months, we decided to rack and switch the new and the 3-year-old barrels to even out the impact of the new oak. The Bound Anthocyanin levels have peaked at around 250 (ppm ME) after one year in the barrels.

In November 2015, we experimented unsuccessfully with cold stabilization on one barrel to reduce acidity. We added 20g of Potassium Tartrate and reduced the temperature to 35 dF for a month to precipitate tataric acid. It did not work because we could not cool down the wine blow 30 dF.

In September 2017, we put the two barrels into Mixing Tank, added 1 lb (1 ppm) of Potassium Carbonite to adjust the pH to 3.55, then bottled 42 cases as 14-13CSCHb leaving 14 gallons for topup as 14-13CSCHTopup. Unfortunately, we failed to stir the wine in the Mixing Tank properly, so early bottles came out with a pH of 3.7 and late bottles with a pH of 3.35!

2015 Vintage

2015 was poor in volume (less than a ½ ton of fruit) and quality (a fair amount of shriveled berries due to a mildew infection). We could fill one barrel only by transferring 8 gallons of the 2012 Bargetto Merlot. We also had to put aside 15 gallons of that blend for top-up wine as we had exhausted other top-up sources.

We made too many interventions during cellaring. In December 2016, we added too much Tartaric Acid to reduce the pH, only to compensate in January 2018 by adding 400 ppm Potassium Carbonate. We added a fair amount of SO2 throughout but still could not contain contamination – Volatile Acidity increased to 1100 ppm. Contamination probably came from the topup wine, a 2013, 14 & 15 Cabernet Sauvignon mixture.

In September 2019, we fined with four egg whites, bottled 21 cases, and saved the remaining 10 gallons for topup.

2016 Vintage

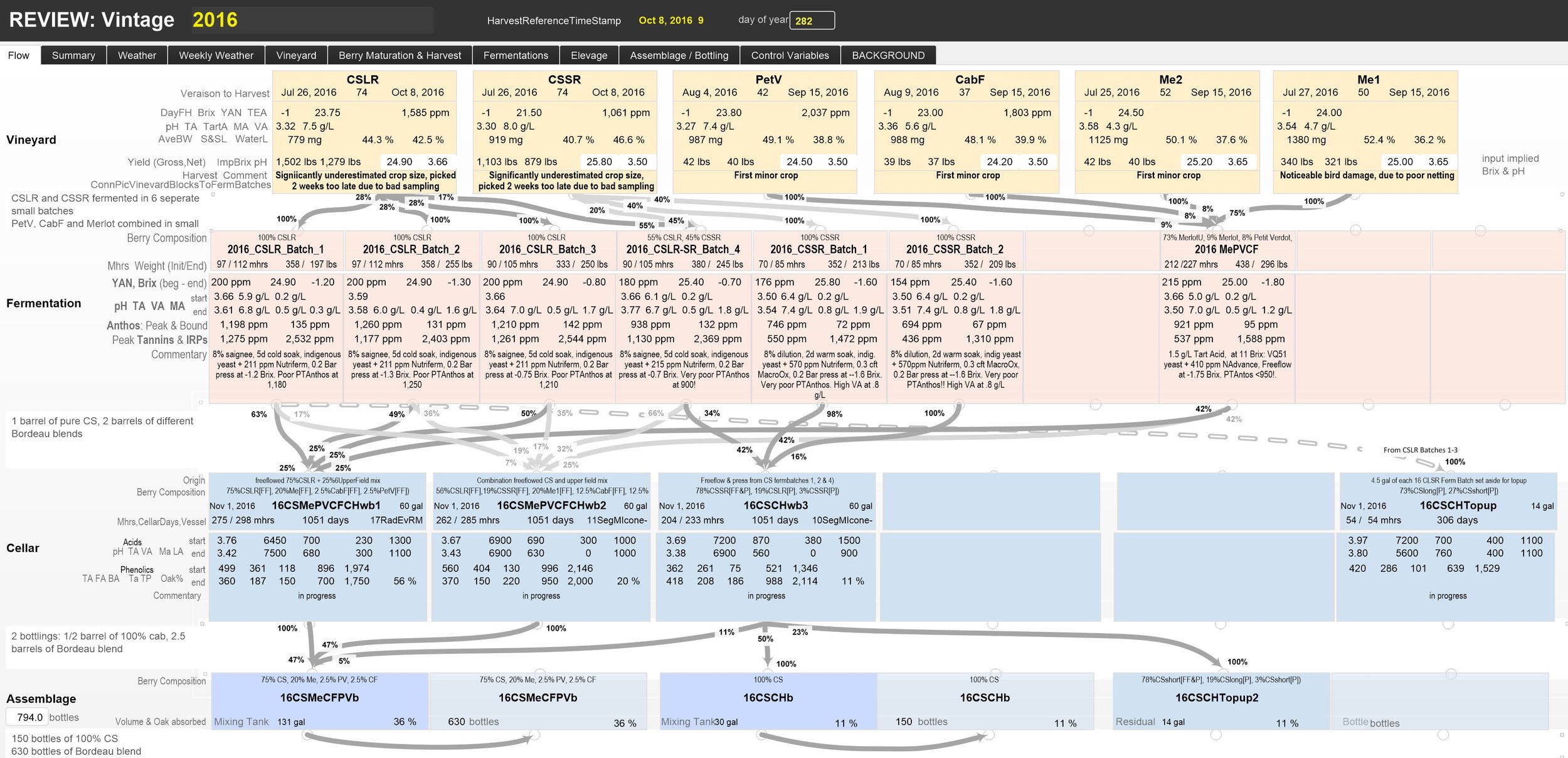

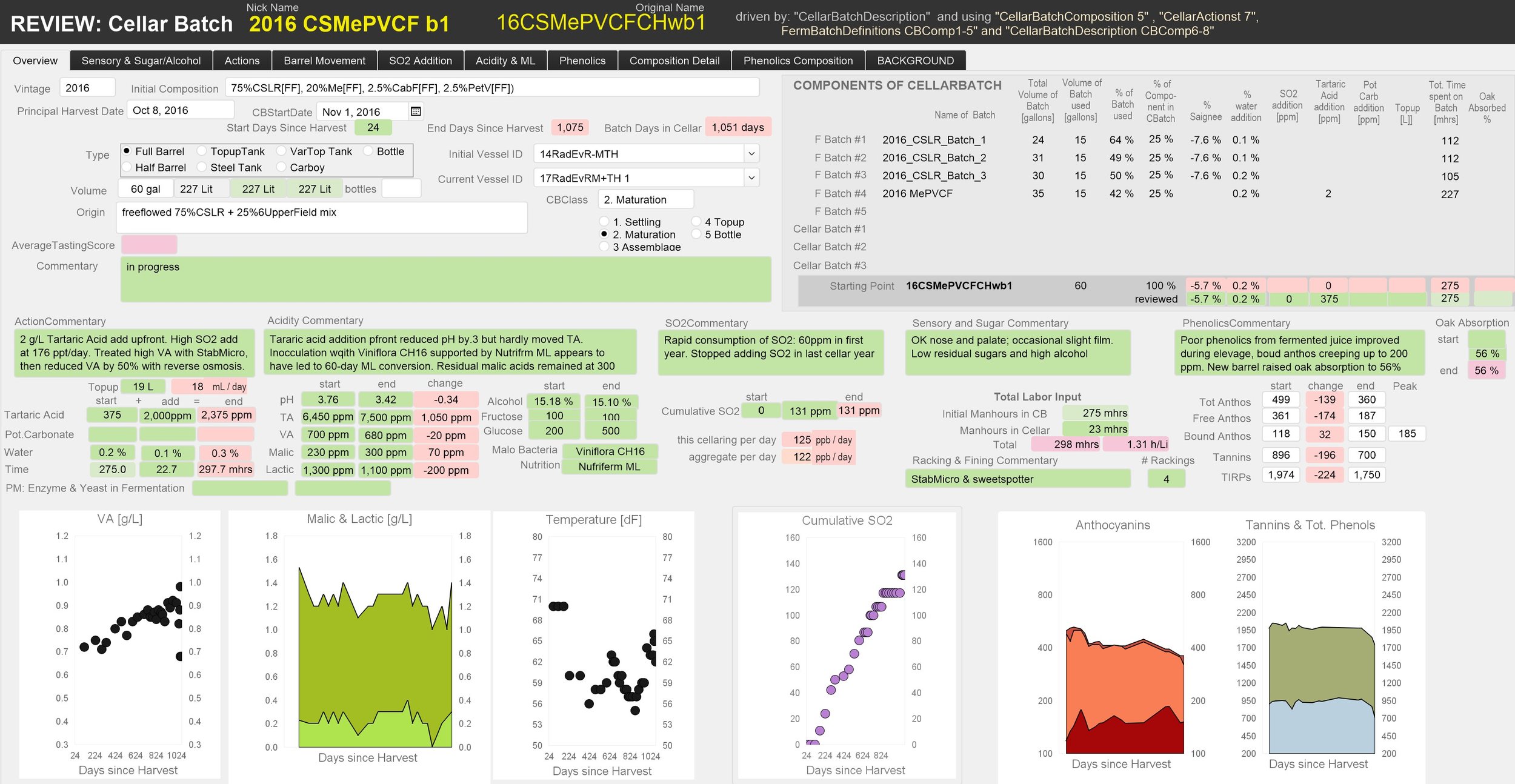

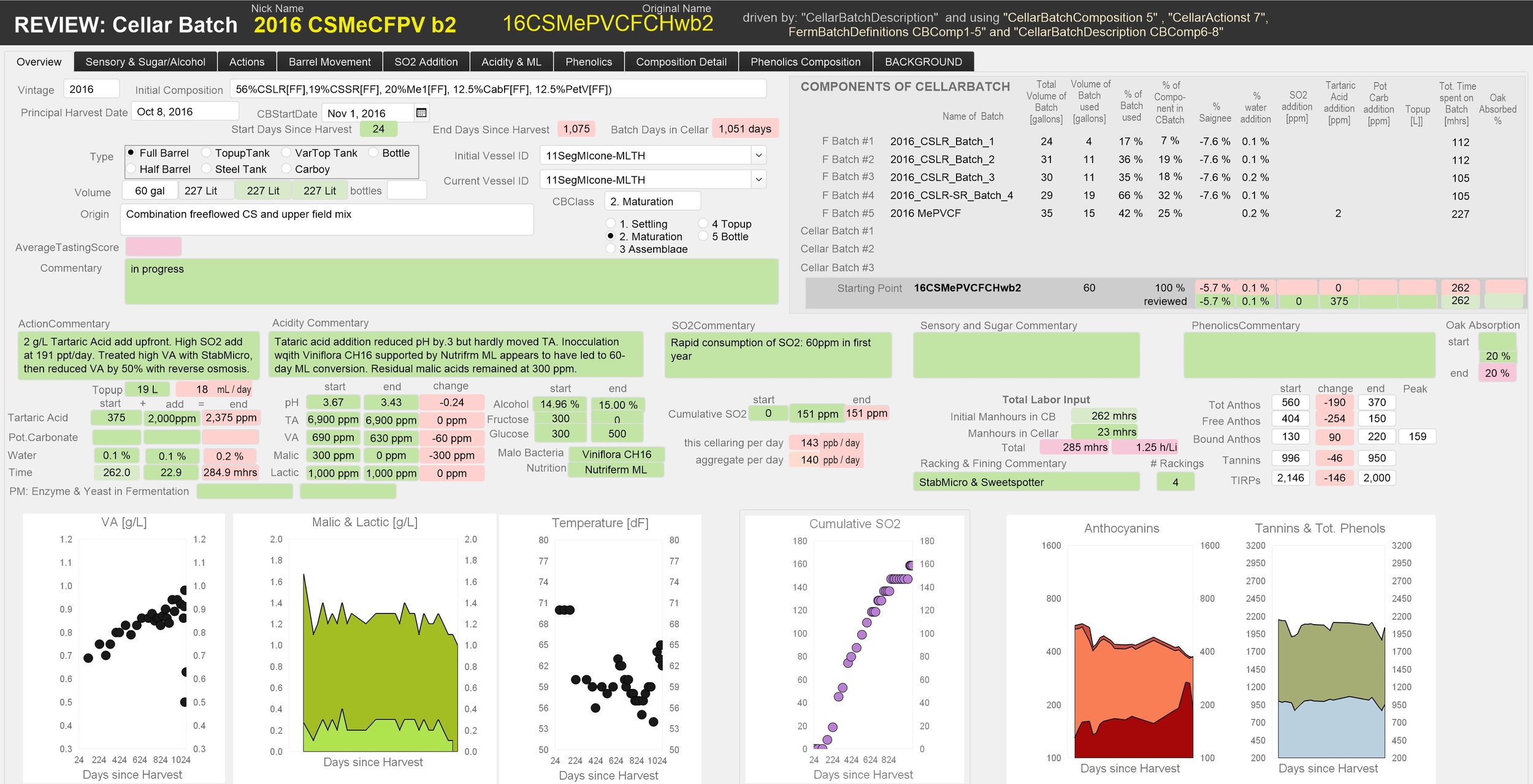

The 2016 vintage included the Merlot, Petit Verdot, and Cab Franc grapes from the upper field for the first time. The yield was above expectation, and the fruit was somewhat overripe. We fermented it in 7 separate batches and free-flowed it into 3 barrels. The first barrel had a mix of Long Row CS plus half the Me-PV-CF crop; The second had a blend of Short and Long Row CS plus the other half of the Me-PV-CF crop. The third mainly had Short Row CS.

We used almost neutral barrels throughout cellaring, so there was limited takeup of tannins. In December 2016 and January 2017, we added close to 1000 ppm Tartaric Acid to each of the three barrels reducing the pH from ~3.7 to ~3.4. We topped up with relatively old vintages (2013 to 2015), probably the source of contamination. Volatile Acidity reached 1100 ppm, and we decided to fine all barrels with StabMicro and then raked and reduced VA with reverse osmosis filtering in August 2019. Surprisingly, the treatment seemed to lift the Bound Anthocyanin levels to over 200 pm.

We bottled half of the pure Cabernet Sauvignon barrel (150 bottles) and mixed the remaining barrels for a Bordeau blend (630 bottles). The pure Cabernet Sauvignon bottles were measured at 3.4 pH, 760 ppm VA, 15.3% alcohol, 190 ppm Bound Anthocyanins, and 2100 ppm TIRPs. The Bordeau Blend bottles measured very close at 3.4 pH, 700ppm VA, 15.2% alcohol, 160 ppm Bound Anthocyanins, and 1800 ppm IRPs.

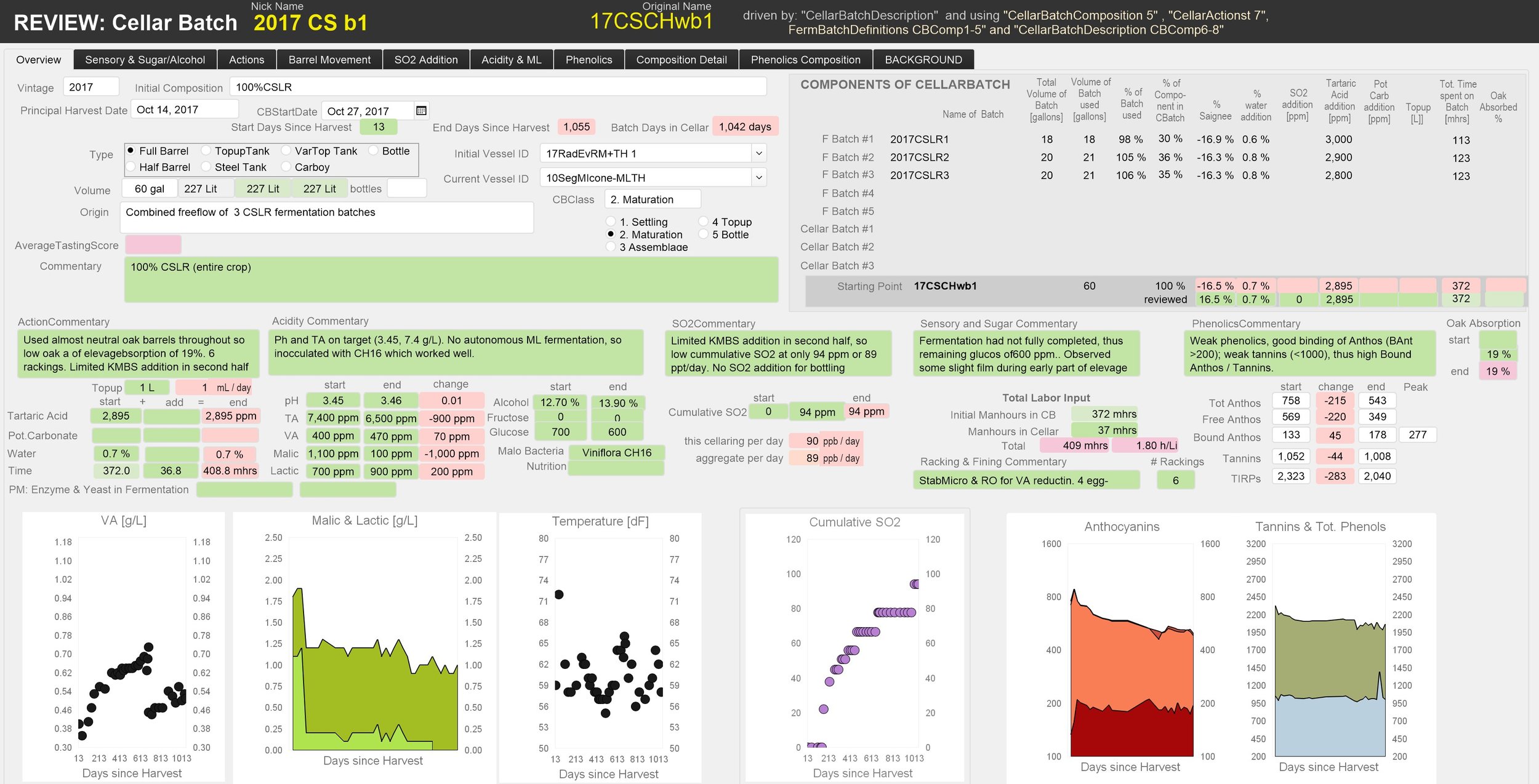

2017 Vintage

The 2017 vintage was poor in volume and quality, primarily because of mildew and severe heat spikes in the summer. We abandoned the Short Row block in the lower field and picked only the Long Row Cabernet, which yielded one barrel. The upper field produced a half barrel of Me-PV-CF mix. We did all fermentations in small batches with indigenous yeast and ended up with an entire barrel of Cabernet Sauvignon from the long rows and a half-barrel mix of Merlot, Cab Franc, and Petit Verdot from the upper field.

We used mostly neutral barrels for the Cabernet Sauvignon, thus yielding a low oak extraction of only 19%, but we used a new half barrel for the Me-CabF-PetV mix resulting in an oak extraction of 80%. We added Viniflora CH16 bacteria without nutrition supplements and completed Malolactic fermentation successfully within a few weeks. We did not have to add any tartaric acid as the pH levels were adequate given our adjustments during fermentation. 2017 was the last vintage in which we used topup wine from previous years, and that may have been the cause for some contaminations. The contaminations prompted us to fine both barrels with StabMicro and then use the reverse osmosis filter to reduce the Volatile Acidity.

In September 2020, we combined the contents of the two barrels in the mixing tank without adding any SO2 before bottling. We ended up with 440 bottles of a Bordeaux blend at pH of 3.40, TA of 6,800 ppm, Volatile Acidity of 550 ppm, Alcohol of 14,7%, and residual Glucose of 600 ppm. The phenolics measured Bound Anthocyanins of 190 ppm, Tannins of 930 ppm, and TIRPs of 2,000 ppm.

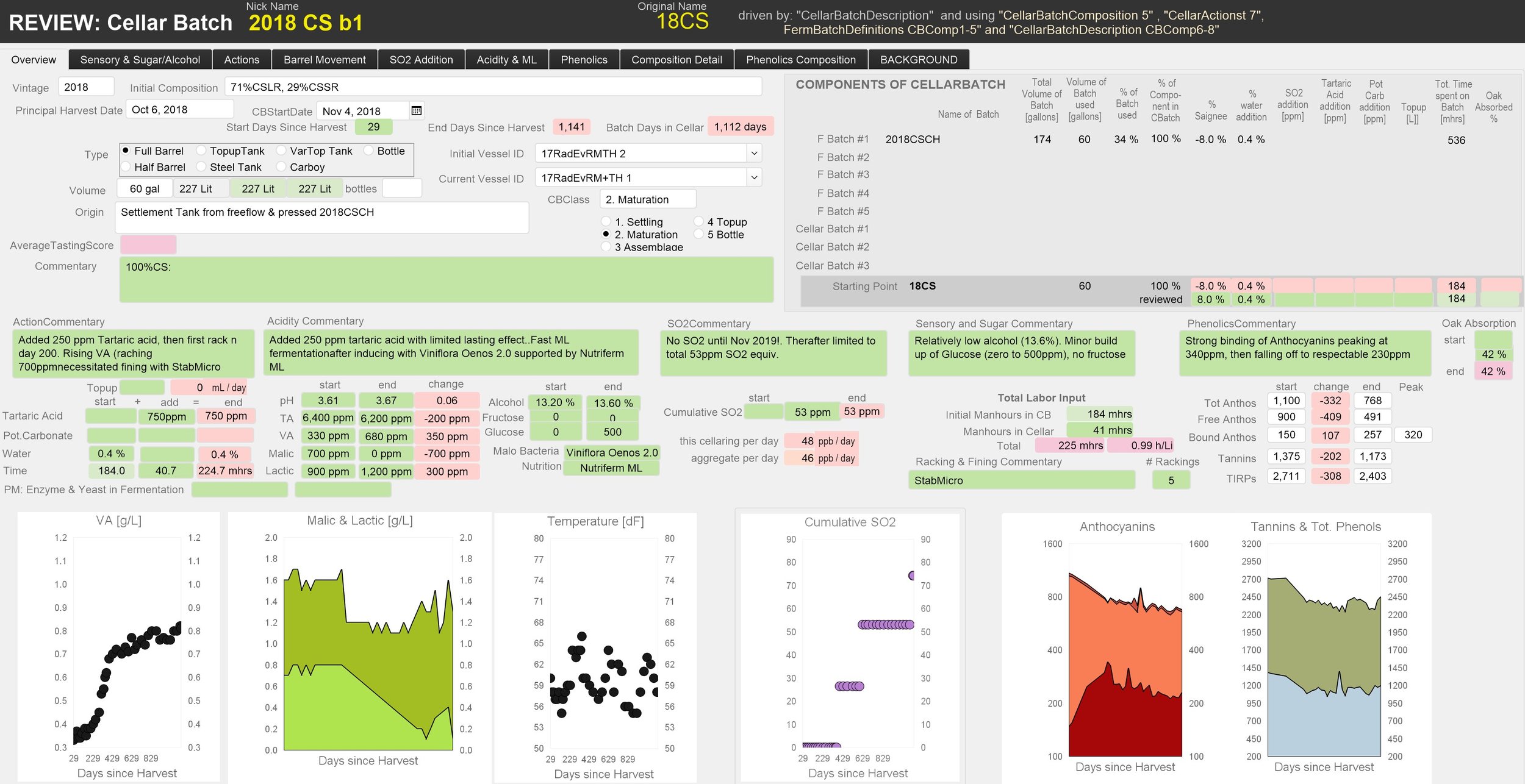

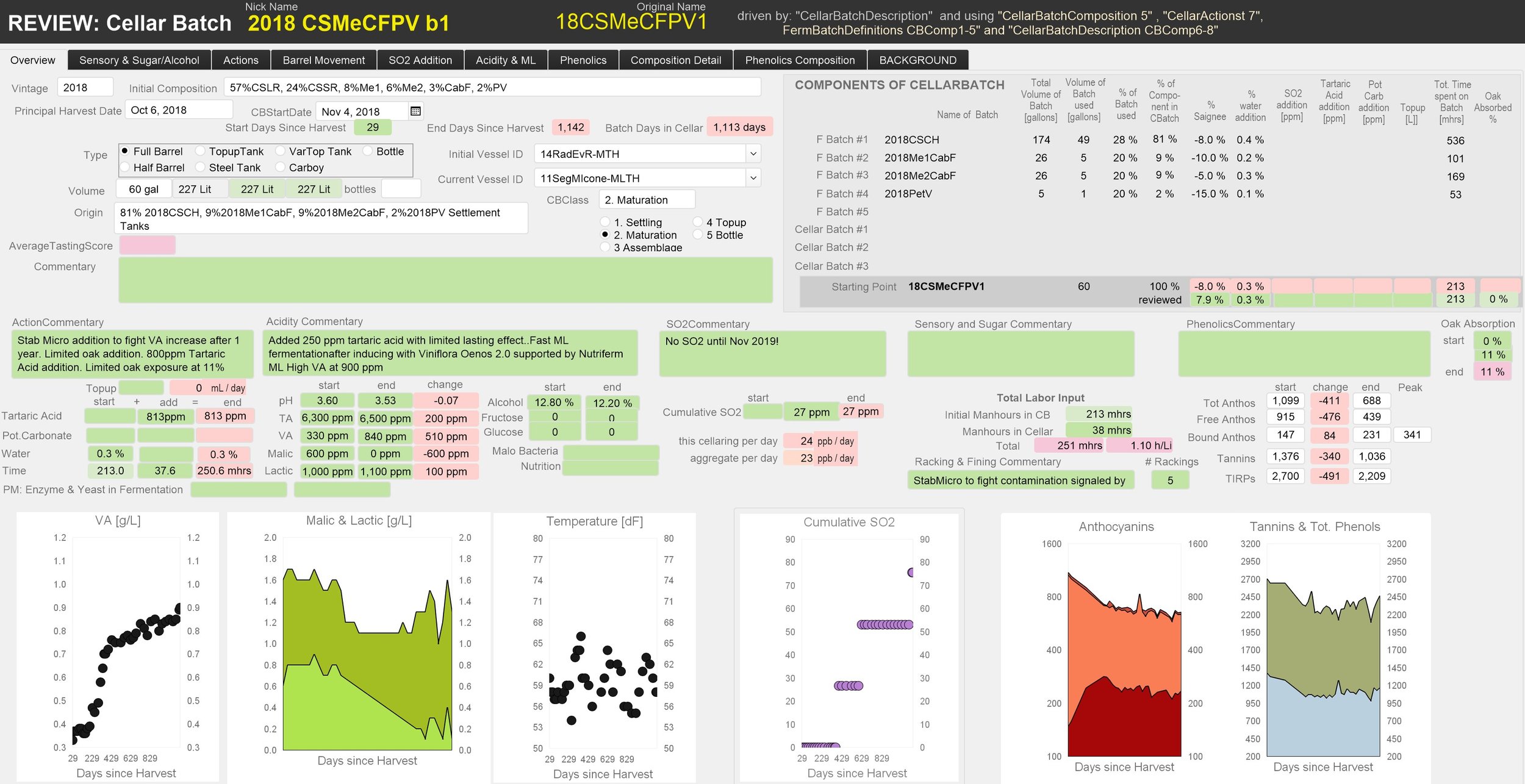

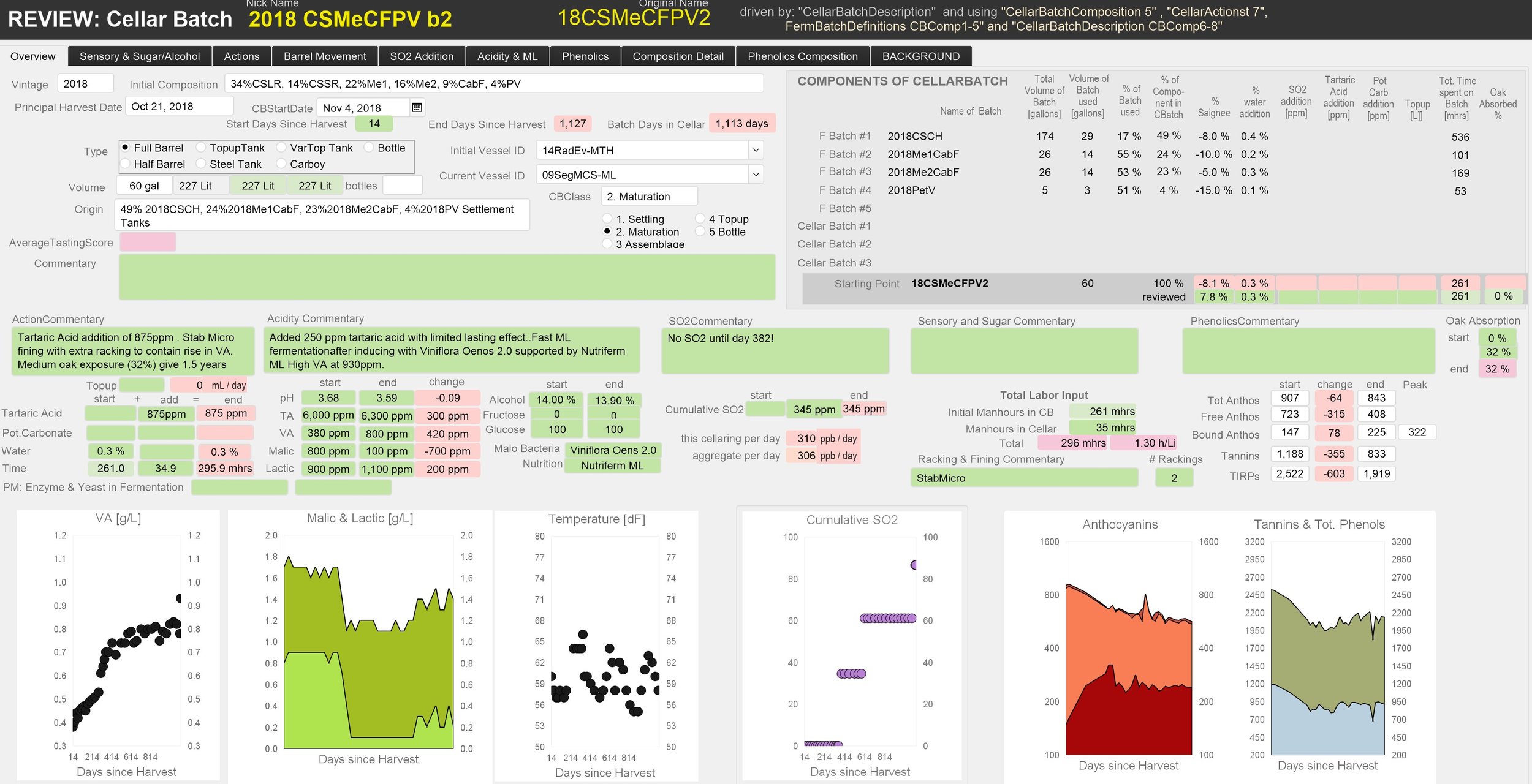

2018 Vintage

The 2018 vintage was excellent in volume and quality, partly due to good weather with only one heat spike. In the winter, soil amendments (mushroom compost & oyster shell lime) and foliar nutrient sprays in spring may have helped. Harvest yield was 3,200 lbs net after less than 25% losses in berry sorting and destemming. We had three picks and fermented the Cabernet in one big batch, the Merlot and Cab Franc together, and the Petit Verdot last. Then we filled 3 barrels (one pure Cabernet, the other two Bordeaux blends). This screenshot illustrates the overall process.

We inoculated with malolactic bacteria (Viniflora Oenos 2) and nutrients in August of 2019. The malolactic fermentation completed in all three barrels. To reduce the chance of contaminations, we used only 2018 wine to top up, and we bought a barrel steamer to more thoroughly disinfect the barrels after each racking. We still needed to fine with StabMicro in September 2019, which contained Volatile Acidity to 800-900 ppm despite a 50% reduction in SO2 additions. We adjusted the pH from 3.65 to 3.45 with four small additions of Tartaric Acids (total ~ 800 ppm). We mainly used neutral barrels, so the accumulated oak extraction was relatively low (42%, 11%, and 32% for the Cab and the two blend barrels, respectively)

In late November 2021, we racked the pure Cabernet Sauvignon barrel directly into 280 bottles at 3.47 pH, TA of 6,700 ppm, and Volatile Acidity of 870 ppm. Alcohol was 14% with residual sugar at 300 ppm. Phenolics were excellent at 240 ppm of Bound Anthocyanins,1,200 ppm of Tannins, and 2400 ppm of TIRPs. A few days later, we racked the two Bordeau Blend barrels into a mixing tank and then saved the blend into 580 bottles at 3.65 pH, 6500 ppm TA, and 890 ppm Volatile Acidity. Alcohol was 14.5%, with residual sugars at 700 ppm. Phenolics were excellent with Bound Anthocyanins at 235 ppm, Tannins at 1,000 ppm, and TIRPs at.2,400 ppm

2019 Vintage

The 2019 vintage was a mixed blessing. We had a lot of rain in the winter, followed by a hot summer with lots of heat spikes. At over 5,200lbs, we had the largest crop since 2009 with clean fruit, netting 4,200 lbs in the fermentation tanks. Berry maturation was skewed: at Brix of 23.7, we had an average pH of over 3.7. We fermented each varietal separately with its natural yeasts but had to add significant amounts of nutrition to compensate for the low nitrogen level in the must. We put the Cabernet in two separate barrels for cellaring and combined the Merlot ferments into a third barrel adding a bit of Cabernet to fill it up. We cellared the Cab Franc and the Petit Verdot in steel tanks. In addition, we kept two topup steel tanks of Cabernet. We used the topup and steel tanks for topping up the barrels. By May 2022, all these tanks were empty except the Cabernet Franc tank.

The Malolactic fermentation completed without adding any bacteria or nutrition. We started the elevage with a stupid mistake for the Cabernet barrels: we intended to add Tartaric Acid to reduce the pH. Instead, we added KMBS powder, translating into a 150 ppm initial shock of SO2. The plan was no addition of SO2 at all. We added around 1,500ppm of Tartaric Acid in 5 installments through June 2020 to all three barrels and the steel tanks, reducing the pH from ~3.75 to 3.50. We used neutral barrels, so the accumulated oak extraction was less than 15% in all three barrel lots. The increased efforts in sanitation (barrel steaming, only using current vintage wine for topup) paid off in slower increases in Volatile Acidity, topping out at 650 ppm. Only the Cab Franc in the steel tank required some fining, with StabMicro in January 2020 and Bactiless in December 2020.

More to come

2020 Vintage

The weather for the 2020 Vintage was dry and cool in winter and spring but punctuated by lots of heat spikes (14) in the summer. Harvest volume was down, and berry quality reduced: low Potential Anthocyanins and a very high average pH of 3.79 at 23.6 Brix. We fermented with indigenous yeast in four batches: Cabernet Sauvignon, Cab Franc & Petit Verdot combined, and two batches for Merlot. The Cabernet fermentation required a lot of nitrogen nutrition and then went out of control, over-boiling at a peak temperature of 99dF, the others remained cool and all completed. Extraction of Anthocyanins was poor throughout. We settled each fermentation in a settling tank before filling 3 barrels: two for 100% Cabernet Sauvignon, one for a Bordeaux blend dominant in Merlot. The Malolactic fermentations completed naturally in the settlement tanks without adding bacteria and nutrition.

For the 2020 vintage, we experimented with a new cellaring process. Each barrel has a dedicated and permanently connected topup tank, and at each racking, we mix the remaining topup wine with the respective barrel. This process ensures that no component is ever not exposed to micro-oxidation through the barrel staves for more than a year. We kept the topup wine in the steel tanks in previous vintages for three years of cellaring.

We refrained from adding any SO2. We increased acidity at the second racking in February 2021 by adding 1000 ppm of Tartaric Acid to all barrels and topup tanks. More to come.

More to come (assemblage).

2021 Vintage

The weather for the 2021 vintage was miserable: an exceptionally dry winter followed by a hot summer with a fair number of heat spikes (7). The situation was exasperated by not having watered the vineyard after the 2020 harvest. The harvest was poor, both in terms of volume (net 2,200 lbs) and quality: we picked with low potential Anthocyanins (1,500 ppm), had small berries but good acidity (pH average 3.4) at Brix of 21.5. We fermented the Cabernet Sauvignon with the Petit Verdot, the Bab Franc, and the two Merlots separately – all with indigenous yeasts. We added significant nitrogen to compensate for low nutrients in the Cabernet. We merged all in a settlement tank and then filled two barrels and three steel tanks with dedicated topup wine.

Malolactic fermentation progressed slowly over three months without bacteria or nutrition, one in a neutral, the other in a relatively new barrel. We added 750 ppm Tartaric Acid in April 2022 for the first time when we racked all containers. More to come

More to cme.

Previous page: Bottle Storage

Top of page: Go

Next page: Home

Last updated: July 16, 2022