"Hetsakais" is Swiss-German and means "there is none", so go figure what "Chateau Hetsakais – we focus on grapes instead" stands for.

Good wine comes from good grapes carefully processed in a clean environment with limited intervention. We learned that this is easier said than done, but we continue up our steep learning curve. Our goal: when drinking our wine, you should feel happier and funnier than your mother ever thought possible. None of our wine is sold commercially, so to drink it, you show up here.

We are located in Saratoga, California, on the eastern side of the Santa Cruz Mountain appellation, where we planted a small vineyard of Cabernet Sauvignon grapes 1997 ("Lower Field"). In the beginning, we focused on learning how to grow grapes and sold them to local wineries. Ten years later, we started building a small winery to process the grapes ourselves and increase storage capacity ("Winery"). 2009 is our first vintage - 100% cab entirely processed and bottled on location (in March 2012). In 2013 we built an air-conditioned bottle cellar in the Barn. In 2014 we started planting the second vineyard with other grape varietals to produce a Bordeaux blend ("Upper Field").

The picture is annotated from Google Maps (clicking here gets you to the source).. For a review of Santa Cruz Mountain Cabernets, see this Vinography Wine Blog.

The purpose of this website is to explain how we grow the grapes (Vineyard), make the wine (Winery), manage and store barrels and bottles (Cellar), test chemical properties throughout the process (Laboratory), and organize our data to generate actionable reports (Data Management). I have learned that I have a chance of fully understanding a process only when I can explain it clearly to somebody else. You are the "somebody else." I welcome your feedback (Feedback)

The five steps to making wine

In a nutshell, here is what it takes to produce a bottle of our wine. Roughly ten years from planting to consumption!

1. Plant a vineyard

The pictures show the planting of the half-acre Upper Vineyard in the spring of 2015. It takes a lot of heavy equipment and hundreds of hours of labor. The cost of the 250 vines (about $5/plant) is a surprisingly small percentage of the total expense

2. Tend the vines

During the first 2 or 3 years, the vines are trained to become strong enough to carry a full fruit load; the grape bunches are cut off early and discarded so the vines can focus on growing the root system, trunk, and cordons. After that, the vineyard requires a significant amount of labor every year for pruning, tilling, spraying, training, netting, and harvest.

3. Build a winery &: cellar

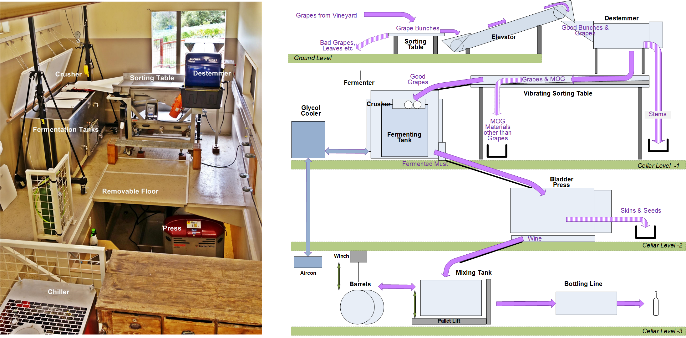

We built our winery in 2008-2009. The building is designed to accommodate the specialized process equipment and the cleaning and air-conditioning requirements. It also houses an extensive laboratory for analysis and monitoring..

4. Make wine:

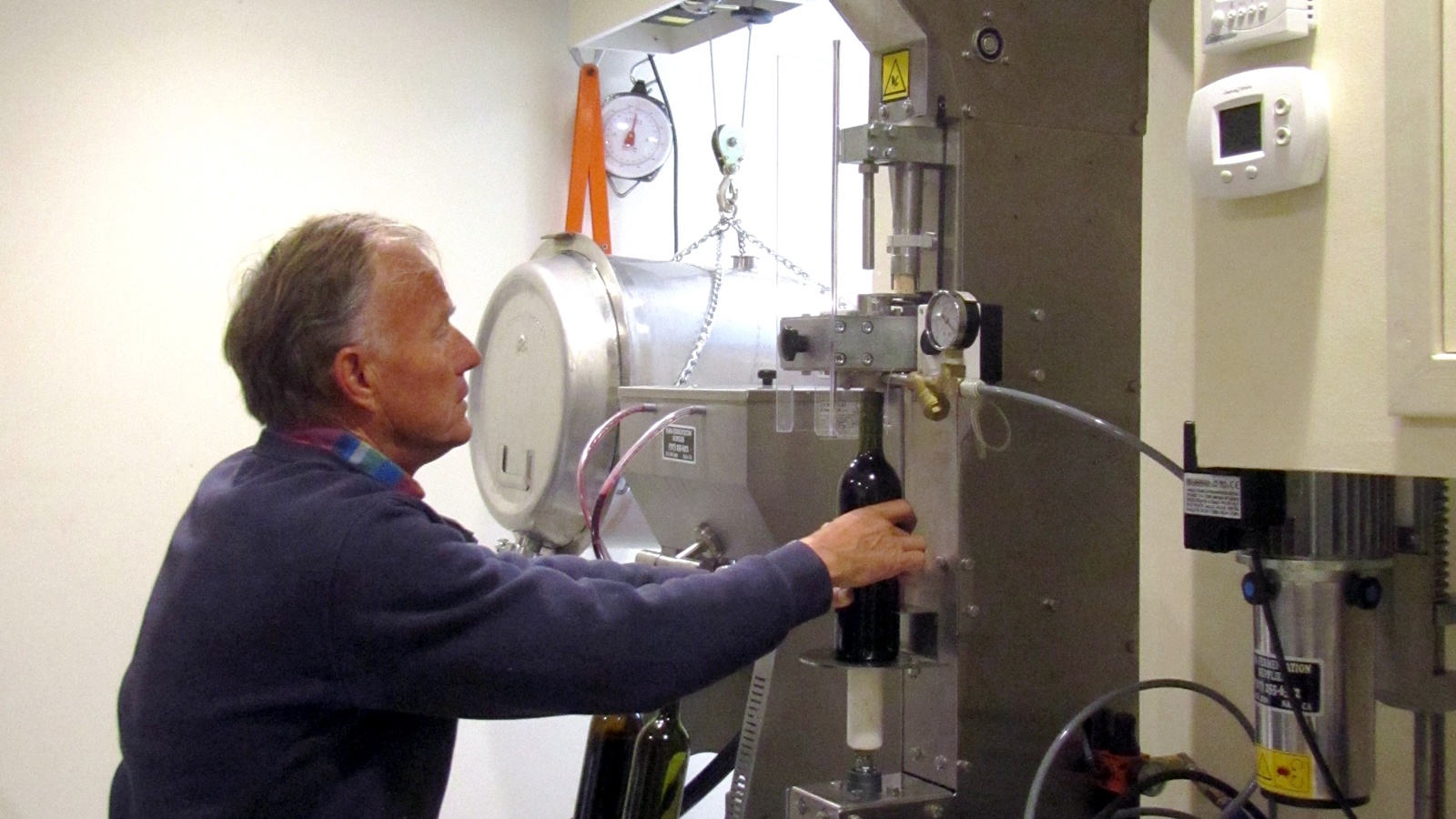

From harvesting to mature wine in a bottle takes around six years. First, we harvest and sort the bunches, destem them and then sort the remaining dirt out of the berries. The result is called must (1 day). Then we ferment the must, press it, and settle the juice from the press in a mixing tank before it goes into barrels. The result is called young wine (3-4 weeks). Then we mature the young wine in barrels, which are regularly topped up and racked (2-3 years). Then we mix wine from selected barrels, bottle the mix, and store the bottles in a cellar until the wine is fully mature (3-4 years). Finally, labels are printed and attached to the bottles.

This venture is a never ending learning experience and an experiment in sharing the insights and pitfalls. Here are my current intentions

Scope: I want to understand and manage at our location the entire process from planting and tending vines in the vineyard all the way to bottling the wine and printing labels.

Do-it-yourself: I want to do everything myself without hiring labor but relying on advice and help from fellow grape growers and winemakers, professional associations, and academic institutions abundant in our area.

Economics: I want to use the latest techniques and technologies in the business if they can be applied to our small scale. This is an enthusiast's hobby for which the only significant financial decision at the outset was defining the diameter of the black hole.

There are many ways to make wine depending on what kind of grapes you start with, what type of wine you want to produce, how much money you want to throw at the process, and, most importantly, how much patience and time you have. We planted Cabernet-Sauvignon vines first and followed ten years later with Merlot, Cabernet Franc, and Petit Verdot to produce Bordeaux style red wine because that is what we like to drink. We bought much fancy equipment because I love playing with machines, and we expect to spend another 20+ years at it, our way of optimizing QTR (Quality Time Remaining).

Website organization

The website is organized into six sections:

Vineyard: here, we explain how we prepared the vineyard sites, how we planted the vines, and what tasks we perform every year, from pruning in the winter through harvesting in autumn

Winery: here, we explain how we designed the winery and how we make young wine out of grapes harvested on location.

Cellar: here, we explain how we age the young wine to maturity over five years, first in barrels then in bottles.

Laboratory: here, we explain our laboratory setup and the extensive series of chemical tests we regularly perform in-house to monitor the grape's maturity in the vineyard and the wine's progress in the winery and the cellars.

Data Management: here, we describe how we organize and manage the data generated by tracking activity in the vineyard, winery, and cellars. After years of juggling spreadsheets, we started developing a relational database in 2017.

Resources: here is where we list our collaborators, sources of academic and professional insights, providers of equipment and supplies, and books worth reading.

Picture Galleries: here, you get a glimpse of how we planted a vineyard, how we built a winery, how we expanded our cellar capacity, and, most importantly, how we celebrate our annual harvests.

We have been at this for over 25 years now, enjoyed every minute, and hope for another 20. We had no family tradition to leverage, but lots of enthusiasm, free resources, and helpful hands around us. I have an engineering background, and I learned that you could not manage what you cannot measure. So we collect many numbers and draw lots of graphs to make sense out of them. Not what you expect from a conventional "vigneron." Vive la difference!

The primary purpose of this website is to document for ourselves what we do. We make it public to enforce quality control on what I write. We hope there are uses for sharing this information, and we welcome your feedback.

Experience to date

The following table summarizes our twelve vintages to date, providing the following information for each vintage:

Ratings & Commentary: We assign a rating between 1 (bad) and 5 (excellent) to each of the critical quality drivers: the weather, vineyard care, berry maturation, harvest, fermentation, elevage, and assemblage.

Weather: we chart one of the most critical drivers of fruit quality: the number of heat spikes, the less, the better

Vineyard: We chart the size of the harvest, the sugar level (Brix), and the acidity (pH) for each of the six vineyard blocks)

Fermentation: We chart the final sugar level (Brix) at the end of the fermentation, the length (days) the juice was in contact with the grape skins, and the average and maximum fermentation temperatures.

Additions during fermentation and elevage: We list what we added in terms of maceration enzymes, yeasts, malolactic bacteria, and fining agents, and we chart the additions of tartaric acid, sulfur dioxide, and oak exposure

Elevage: We chart beginning and ending acidity (pH), volatile acidity, bound & total anthocyanins and tannins & total iron-reactive phenols (IRPs)

Many of the terms used here are very technical and will be explained in detail later. The key message is: Every vintage is different. The weather changes, the vineyard is treated differently, and we adjust how we treat the wine during fermentation and cellaring (elevage)

A few highlights for each vintage:

2009: We harvested 2600 lbs of good fruit and vinified it with a minimal amount of intervention to set a baseline against which to evaluate subsequent efforts. Most importantly, we fermented with indigenous yeast.

2010: From 2010 through 2016, we used commercial yeasts to ensure that the fermentation completes. In 2010 we harvested slightly less fruit (2000 lbs) because the vines started to be affected by an infection (Eutypa). We vinified using the full range of tricks known to an inexperienced winemaker: We cold soaked, we used enzymes, we used industrial yeasts, and we gave the juice extended exposure to the skins. The result was a wildly over-extracted wine (prolonged skin contact, extended exposure to new french oak)

2011: Deplorable weather conditions reduced the yield (only 1000 lbs harvest) and the grapes' ripeness (only 22 Brix). The result was a relatively light wine with low anthocyanins (color) and low tannins.

2012: A good year weather-wise resulting in a healthy crop of close to 2000 lbs. We bought some Merlot grapes for blending. We started to use phenolic analysis to get a better handle on the fermentation process. Fermentations overheated and did not fully complete. We added a lot of SO2 to prevent spoiling in the barrels. We ended up with a wine with solid color and tannins.

2013: An exceptional year weather-wise resulting in excellent fruit (note the high Anthocyanin levels). The phenolic analysis guided us for the first time to press the skins before fermentation was complete. We also had problems with the Malolactic fermentation – it took much longer and never completed. We ended up with a wine with intense color (anthocyanins) and elevated tannins.

2014: Another good year weather-wise, but with a reduced crop because the Eutypa infection was spreading in the vineyard. We picked a bit late and lost acidity, so we had to add tataric acid during fermentation. We tried fining with cold stabilization to remove tartrates but were not successful. We ended up with high levels of volatile acidity, good color, and tannins.

2015: A miserable vintage in terms of volume (due to Eutypa), quality of fruit (mildew due to inadequate spraying), and wine-making. We vinified the different cabernet clones separately and so, for the first time, realized the significant differences in fruit quality in the vineyard. Still, we combined the three separate fermentations in a single barrel. We added a lot of SO2 but still ended up with high volatile acidity. We added too much tartaric acid, so we had to compensate with Potassium Carbonate before bottling, but we failed to mix it in well. In short – a comedy of errors.

2016: From 2016 onwards, we reverted to indigenous yeasts and stopped using maceration enzymes. 2016 was the first year we picked the upper field with Merlot, Cabernet Franc, and Petit Verdot grapes to get a true Bordeau blend. The vines recovered from Eutypa, so the yield in the lower field started to recover. We picked 1-2 weeks too late due to sampling errors, so we lost acidity, which we compensated by adding tartaric acid. We continued to have bacterial infection problems in the barrels, so we needed to fine with StabMicro and reduce volatile acidity with reverse osmosis filtering. The judgment is still out whether the wine will overcome all the interventions.

2017: Severe heat spikes ruined the fruit maturation and masked mildew infections. We did not even pick the short rows in the lower field and ended up with less than 1900 lbs in the tanks. We fermented in 7 separate fermentation tanks and added a large amount of tartaric acid to reduce the pH. Then we free-flowed (no press) the fermented juice into 1 ½ new French oak barrels. Again we fought bacterial infections in the barrels with StabMicro fining and reverse osmosis to reduce volatile acidity. Not a good vintage

2018: The moderate summer without heat-spikes was good for the quality and quantity of the crop. We harvested around 3,000 plus 1,000 lbs in the lower and upper fields, respectively – all good quality. We fermented with indigenous yeast in 4 tanks and combined the resulting wine in 3 oak barrels with different mixes. We invested n a barrel steamer to fight bacterial infections. Overall, a promising vintage with excellent color, solid tannins, and acceptable levels of volatile acidity without fining.

2019: A record number of heat-spikes screwed up the maturation. We had the largest crop ever with great-looking grapes, but the acidity vanished before the grapes fully matured, so we again needed to add tartaric acid. By mistake, we added far too much SO2 to the Cabernet Sauvignon after barrelling – our strategy is to reduce SO2 additions to retain deeper color (anthocyanins). The Cabernet Franc needed a StabMicro treatment to slow down the buildup of volatile acidity. At best, an average vintage

2020: Another year with lots of heat spikes impacting berry maturation and acidity. Harvest volume was good, but the pH was way above target. Too much macro-oxidation during fermentation of the Cabernet Sauvignon led to a boilover with temperatures reaching close to 100dF. We permanently attached dedicated top-up tanks to each barrel to reduce oxygenation and spoilage during elevage further.

There are, alas, a few technical terms in the preceding paragraphs – we will explain them in the subsequent sections of this website.

Lessons learned

Here are some of the insights I have gained so far:

Vineyard trumps winery: the most critical input to excellent wine is excellent, clean grapes. You cannot make great wine out of mediocre grapes, but you can easily make mediocre wine from great grapes. So it is essential to understand and control the vineyard first.

The average quality of commercial wine has significantly improved over the last 30 years. During the same time, the inflation-adjusted costs have dropped. The industry has learned to streamline production processes and eliminate bacterial contamination. Industrialization, global branding, and distribution have increased volume and quality but significantly decreased diversity. Today 99% of global wine production is "manufactured industrially" and controlled by 1% of the brands. Gallo, for example, is said to produce 900 million bottles per year and their production facilities look like oil refineries. Small wineries can only stay commercially viable if they create a unique product for a local market – and many do. At our scale, we will always remain an expensive hobby.

The scientific understanding of what exactly makes superior grapes and wine is surprisingly limited. We know what makes lousy wine, and we measure a lot of stuff because we can, and it helps to reduce mistakes. Making great wine is a craft honed over decades if not generations of experience – and the tricks are seldom shared. In our situation, we keep our ears to the ground to pick up ideas and tricks while we track numbers so we can at least learn from our mistakes.

In the past, we analyzed wine in “wet” laboratories using lots of reagents and glass. That was very slow and labor-intensive. Today, we analyze wine by looking at its spectral properties. The instruments are costly, but they produce results quickly at significantly reduced labor costs - another driver of scale and industrialization.

Only well-established brands need to make similar wine every year – because that is what the consumer expects. The boutique wineries have the freedom to make the best of what the year's grape can give. A good winemaker in a large winery makes the same sound wine regardless of the grape characteristics' yearly change. A good winemaker in a small winery makes a new wine every year, exploiting the annual differences in grape characteristics – the jobs are different but equally challenging. Our goal is the latter.

We developed this website's content first in Microsoft Word, with tables and charts in Excel, graphics in Visio, and pictures edited in PhotoScape. Since 2017 we collect and manage data in FileMaker, a relational database. The contents of the word document are transferred to a Squarespace platform and hosted on Google.

A website is not the ideal medium to hold what is essentially a giant living document. It is suitable for browsing but cumbersome to read at length. To help out, we post recent pdf files of the different sections in the links which follow, so you can download and print or read offline

Link to Resources Section pdf

These links are also provided at the end of the Overview page in each Section. If you like to get alerts when any of pages in this website get updated, subscribe to my Twitter feeds @TillGu or @tguldimann; click here (https://twitter.com/TillGu or https://twitter.com/tguldimann)

Here is a link to a pdf file of the HOMEPAGE as of May 16, 2023

Last Updated May 16, 2023

Top of this page: Go

Go next to