Initially, we built a conventional wet laboratory with lots of glassware and reagents to measure basic chemical properties. As a consequence, we learned a lot about introductory chemistry. However, measuring multiple samples every few days proved very time-consuming. So, in 2017, we purchased an OenoFoss Analyzer to replace the bulk of the glassware and reagents.

OenoFoss Analyzer

The Analyzer uses Near Infrared ("NIR") Spectrometry defined by wavelengths between 700 and 2500 nanometers. FOSS is a Danish company with a dominant food and agricultural analytics position. The key advantages of using OenoFoss are that it works with tiny samples (1 mL), returns results within only 2 minutes, and requires only infrequent calibration. The main disadvantage is cost. The instrument measures the following properties simultaneously:

sugars (Brix, Glucose, and Fructose),

alcohol (% Alcohol, Density),

acids (pH, Total Acidity, Volatile Acidity, Malic Acids, Lactic Acids, Tartaric Acids, Gluconic Acids), and

nutrients (Yeast Available Nitrogen: Alpha Amino Acids, Ammonia

For more details, see https://www.fossanalytics.com/en/products/oenofoss

We use an Eppendorf 5424 centrifuge (https://www.eppendorf.com/product-media/doc/en/330723/Centrifugation_Operating-manual_Centrifuge-5424-R.pdf ) for clarifying samples that contain suspended particles larger than 1 micrometer. (for more information, see the following page)

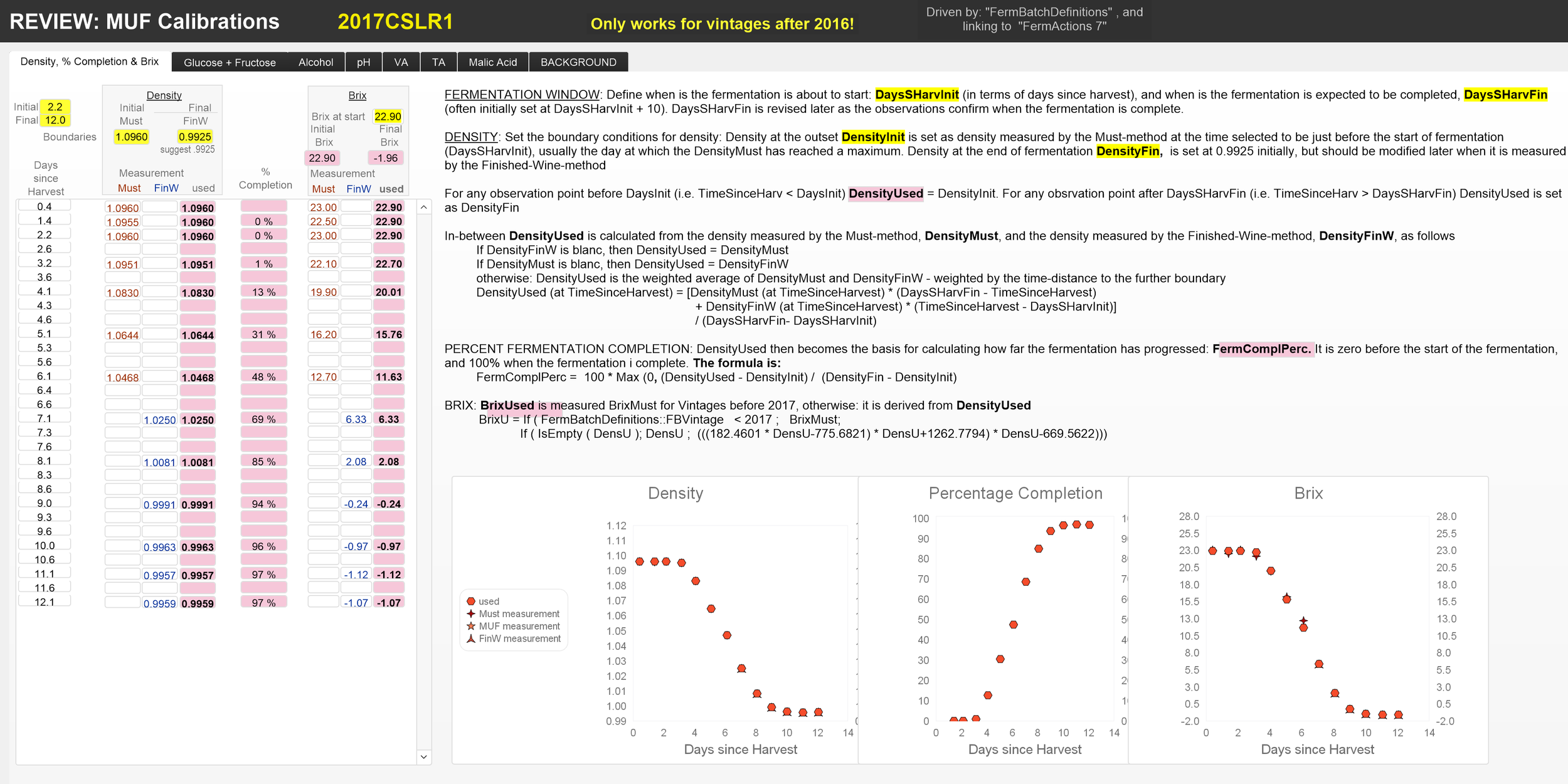

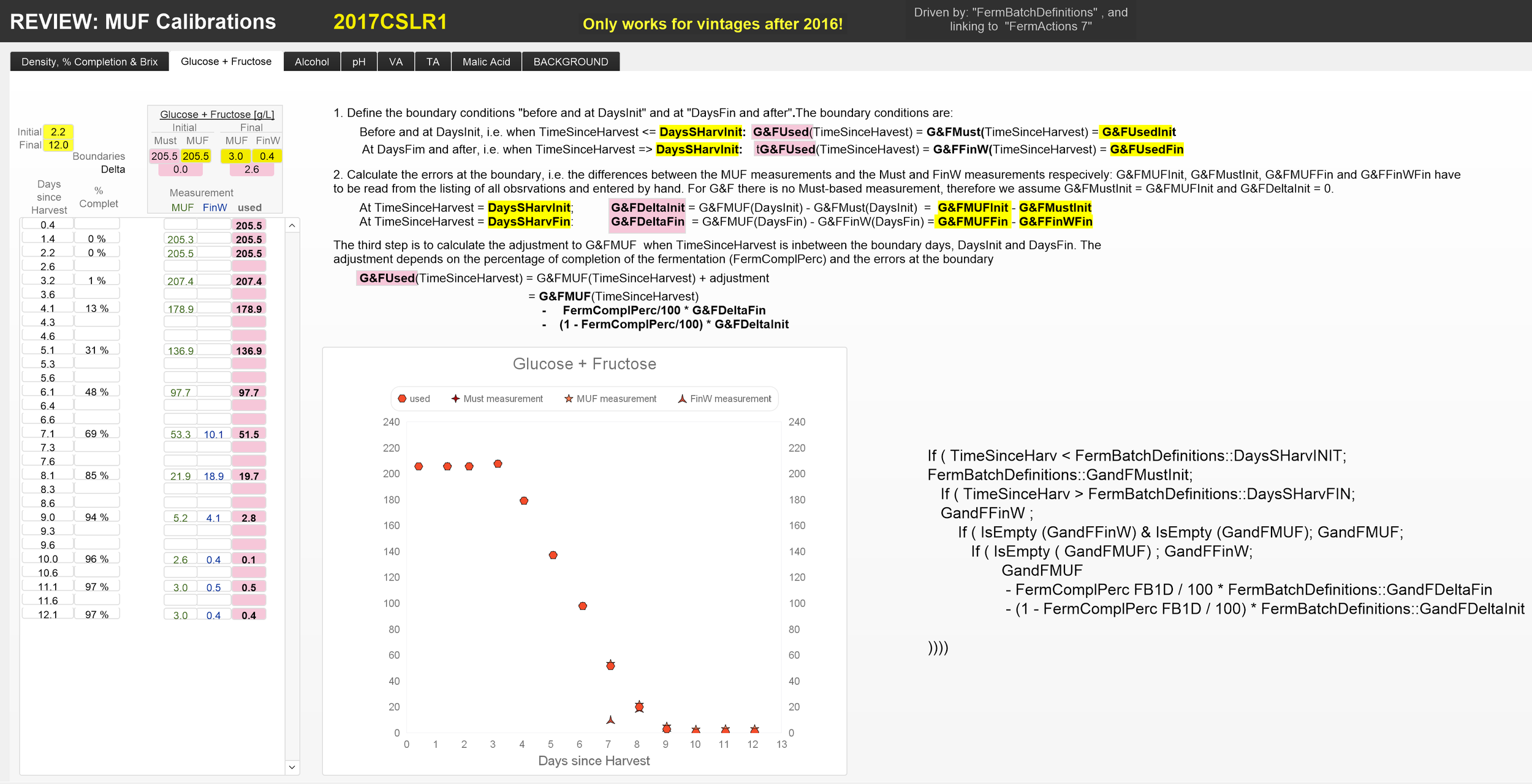

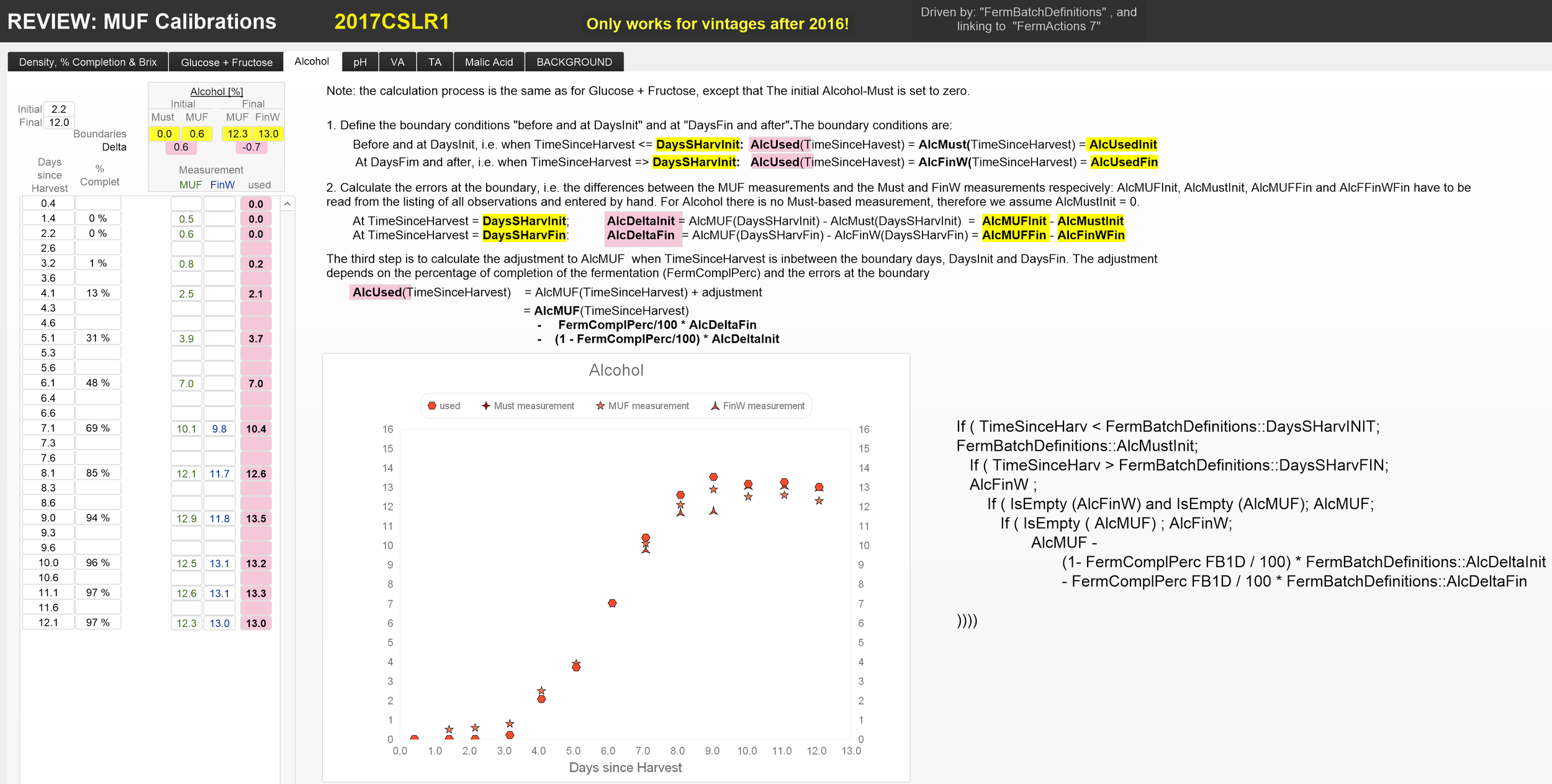

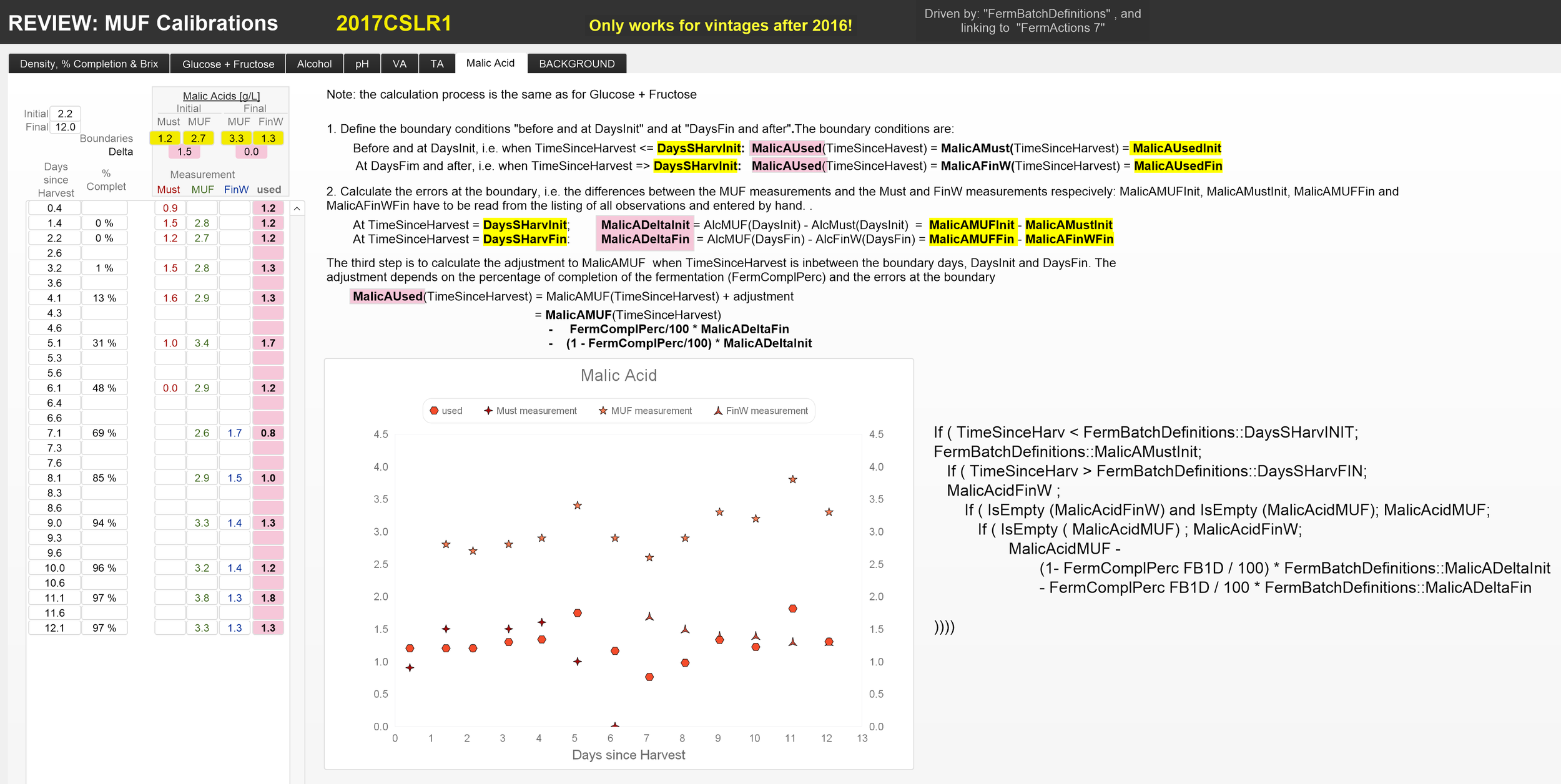

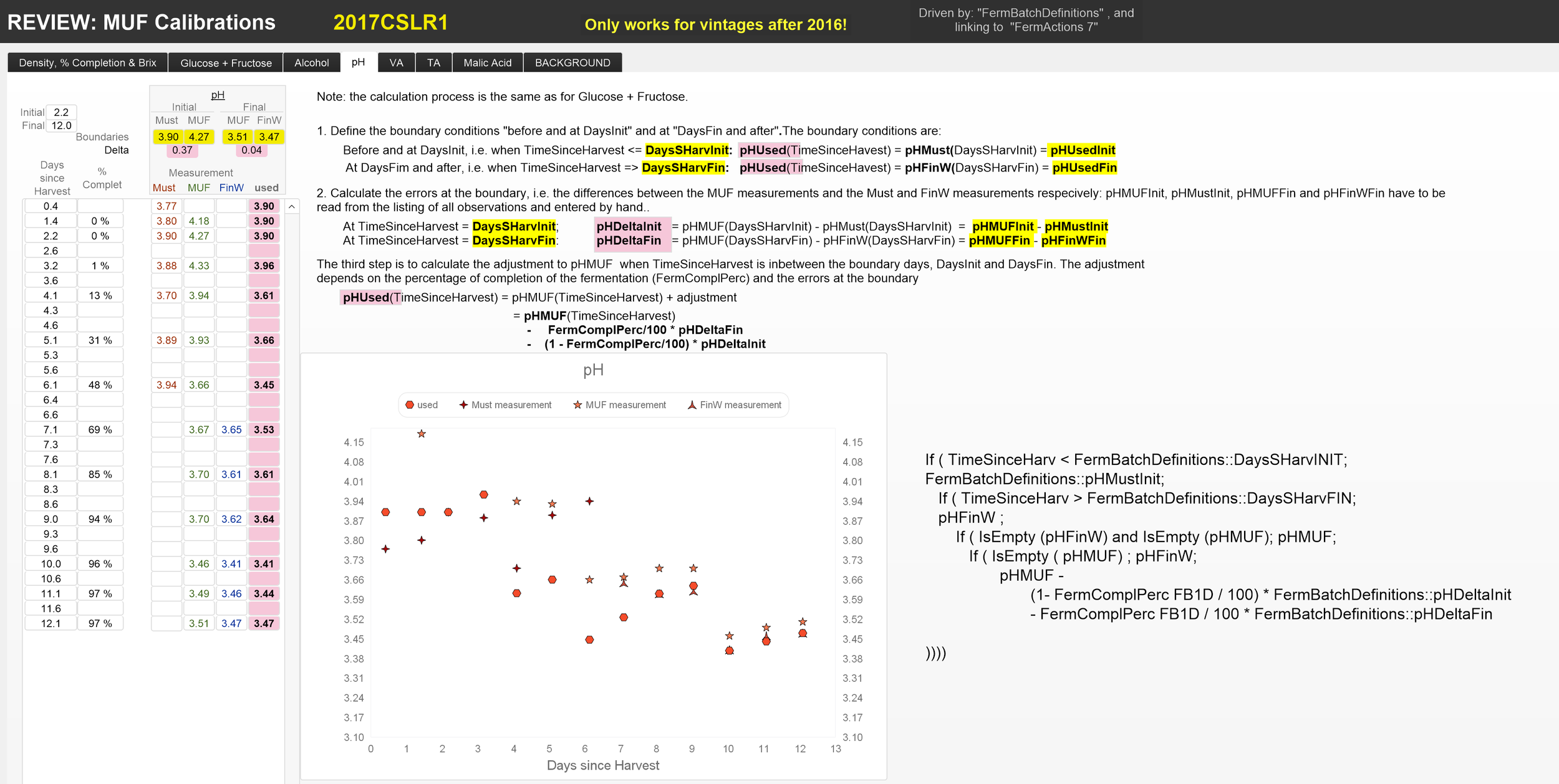

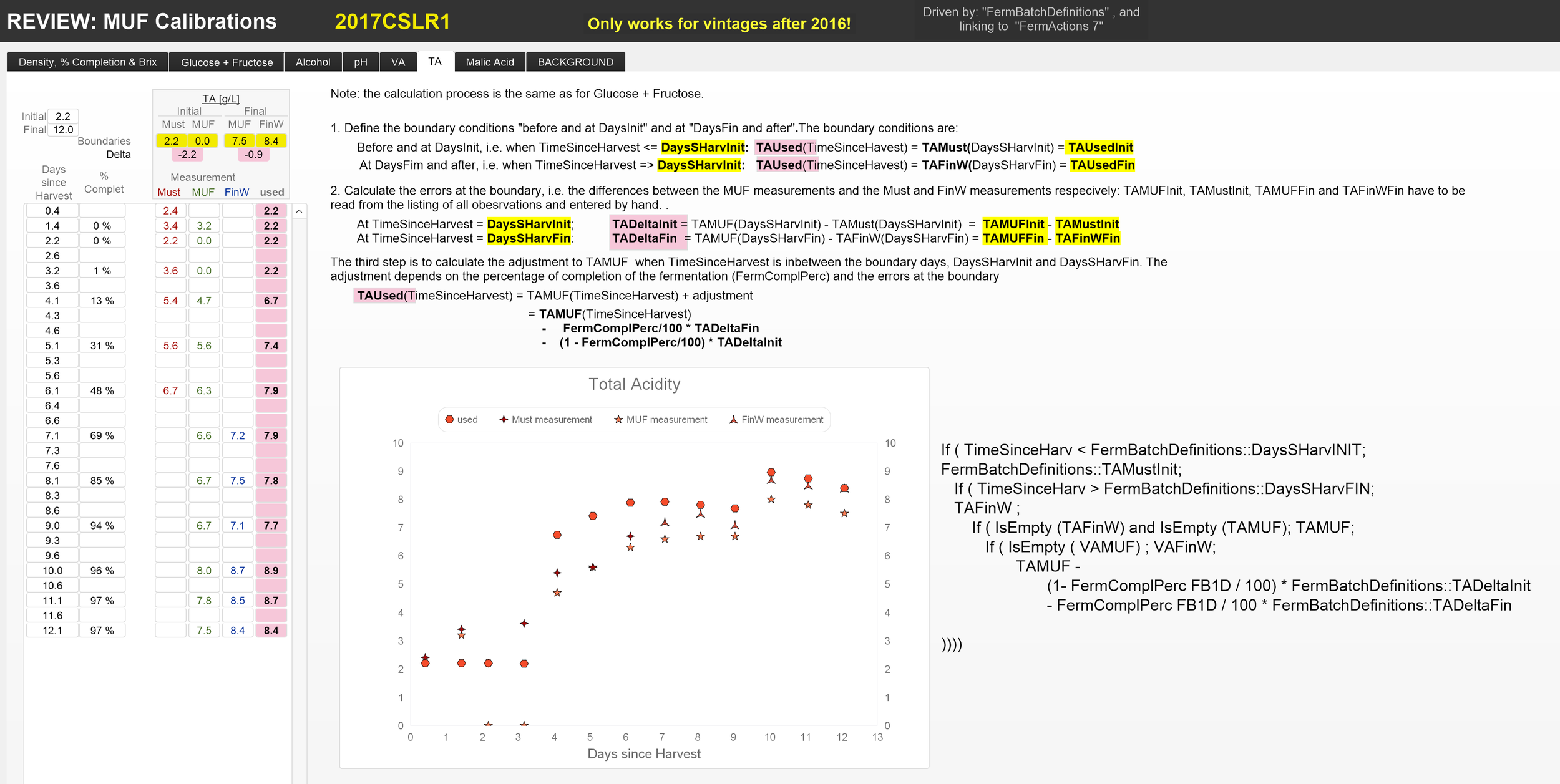

Calibration for measurements during fermentation

Foss calibrates the Analyzer for two measurements: for unfermented grape juice and must ("Must") or fully fermented must ("Finished Wine" or "FW"). Measures during fermentation ("Must under Fermentation" or "MUF") need to be adjusted by the boundary conditions at the beginning and end of the fermentation. We know that the "MUF"-measurements at the very beginning of the fermentation are still correct, i.e., calibrated, and we know that the "FW" measurements at the very end of the fermentation are also accurate, i.e., calibrated. The measurements during fermentation, which are not pre-calibrated, must be adjusted. In a nutshell, we adjust the MUF measurements by linearly interpolating the errors at the beginning and end of the fermentation. The adjustment to the "MUF" measurement at the beginning is the difference between the "Must" and "MUF" measurements. The adjustment at the end of the fermentation is the difference between the "MUF" and the "FW" measurements. In between, the adjustment is the linear interpolation between the initial and the final adjustment based on the percentage of completion of the fermentation. Consequently, the adjusted measures are only firm once the fermentation is complete.

We enter the Must, MUF, and FW measurements in the INPUT: Fermentation Actions by Harvest for all active fermentation batches. This screenshot illustrates how we entered the data for four fermentation batches on October 15, 2017, at 6 pm. The white boxes hold the Must, MUF, and FW data provided by the Analyzer, and the colored boxes under "Value Used" show the adjusted measures.

The adjusted measures will only be computed after the interpolation parameters have been established. The process of adjustments is documented in the layout REVIEW: MUF Calibrations. The following eight screenshots show different tabs in that layout for the fermentation batch 2017CSLR1 at the end of the fermentation. Each of these tabs shows what boundary conditions need to be defined and how the adjustments are calculated. Each tab also contains a graphic of the raw and the adjusted measures. Note this MUF calibration needs to be updated at the beginning and end of each fermentation.

Previous page: Overview Laboratory

Top of page: Go

Next Page: WineXRay for measuring phenolics

Last updated: March 3, 2023