Measuring Dissolved Oxygen

Definition and Relevance

Oxygen supply is essential during the fermentation of must; it keeps the yeast growing. But, once yeast cells stop multiplying, excess oxygen encourages the growth of microorganisms. In barrels during elevage, extra oxygen can lead to accelerated wine aging. So we add oxygen during the early fermentation phases and control the wine's exposure to oxygen once it is in the barrel.

Oxygen dissolves in wine, as it does in water. Wine can dissolve oxygen up to around 8 ppm or mg/L at 60 °F (significantly more at lower temperatures). Measuring DO is tricky because sampling can expose the wine to air.

Measurement

In the past, we tried to measure DO electromechanically (taking a sample and measuring a charge difference across a membrane). The instrument required is relatively inexpensive, but the measurement turned out unreliable because a sample must be extracted and probed, exposing it to oxygen in the air. We also experimented measuring DO with a Portable Dissolved Oxygen Meter HI9146 from Hanna (see http://www.hannainst.com/usa/prods2.cfm?id=004002&Pro°Code=HI%209146). Neither led to valuable insights, so we stopped experimenting with electromechanical probes.

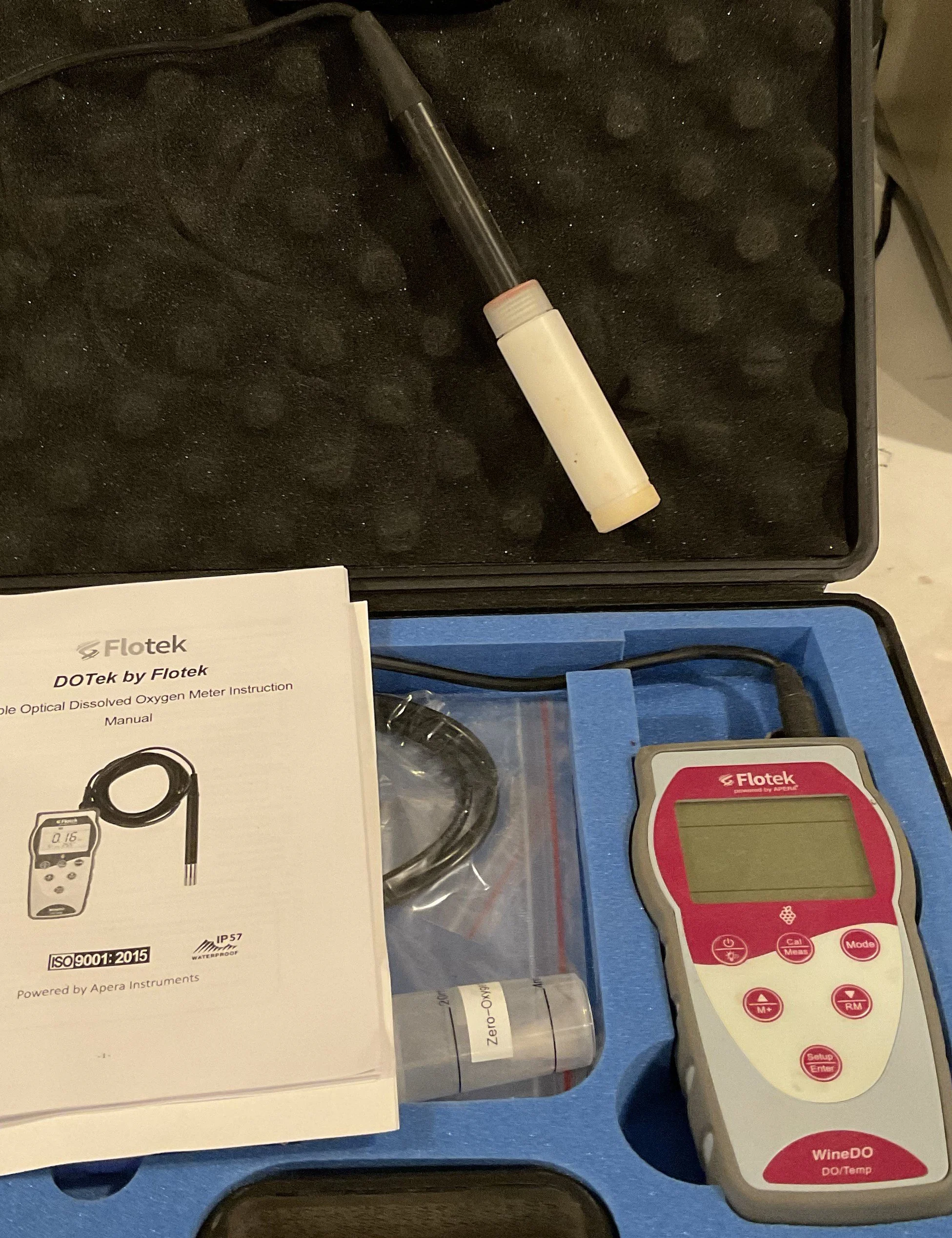

In 2019 we bought an optical DO meter from Flotek. To experiment with measuring DO in three situations:

1. In must before and during fermentation. Yeast growth and replication depend on and absorb a fair amount of oxygen; that is one reason for vigorous punch-downs and/or macro-oxidation (injection of air or pure oxygen) in the must during the first half of the fermentation. We thought the DO measurement before and after each punch-down or injection should allow us to manage better the intensity of punchdowns and the diffusion of oxygen. It turns out that measuring the Oxidation Reduction Potential ("ORP," see earlier page) is more promising for monitoring yeast health.

2. In wine, during cellaring: The goal is to minimize the dissolved oxygen. Oxygen (except when added in tiny doses, i.e., controlled micro-oxidation in steel tanks) ages the wine prematurely and increases the chance of spoilage through microorganisms. Wine is exposed to oxygen each time we open the barrel for topping up or racking. Consequently, we measure DO before each topping up, before and after racking, and most importantly, before bottling. We stopped measuring DO in 2020 when we introduced a new top-up process which eliminated having to open up the barrels.

3. In wine to, measure its oxygen absorption capacity: The more oxygen and the faster a wine can absorb oxygen, the longer its expected future life and, thus, the ability to mature further. We experimented with measuring the oxygen absorption capacity in test bottles by forcefully increasing the dissolved oxygen level to its maximum (by vigorously shaking the bottle, thus dissolving air), measuring the DO, then capping the bottle and measuring the DO over time recording how fast and to what level it falls (i.e., how fast the dissolved oxygen gets absorbed)

Previous page: Measuring and Adding SO2

Top of page: Go

Next Page: Measuring Dissolved CO2

Last updated: March 30, 2023