Measuring and Adding SO2

Practically all wine is made with Sulfur Dioxide, SO2 - repeatedly added in small doses to prevent spoilage. Still, wine can be made sulfur-free but requires rigorous sanitation and processing techniques (Frey Vineyards is a trailblazer in sulfur-free wines, http://www.freywine.com/). We stopped using sulfur in 2020, except at bottling.

Sulfur degrades certain enzymes that spoil the wine by oxidizing phenols; this is its role as an antioxidant. A specific form of SO2 also kills bacteria and non-Saccharamyces yeasts by entering through their cell walls. There are four different instances when we consider adding SO2:

Right after grape sorting and before cold soak - if fermentation will be done with non-indigenous yeasts. The purpose is to kill off all indigenous yeasts first

After the malolactic fermentation has finished.

During cellaring, whenever barrels are topped up or racked.

Just before bottling

In 2016 we stopped using commercial yeast and relied instead on indigenous yeast to manage the fermentation; thus, we stopped adding SO2 before cold soak. In 2021 we stopped adding SO2 after malolactic fermentation to reduce SO2 additions further. We still add small amounts of SO2 before bottling.

On this page, we describe how we calculate the amount of SO2 we added in each of the four instances and how we measure the concentration of SO2 in the wine before and after.

Different forms of SO2

The story is convoluted because only a portion of the "Total SO2" added is effective; that portion is called "Molecular SO2"; however, you can only measure and control "Free SO2". Total SO2 is the sum of Bound SO2 and Free SO2.

Bound SO2: When adding SO2, a good portion of it becomes immediately bound to sugars, acetaldehydes, and phenolic compounds (called "Bound SO2") and becomes ineffective; the remainder is called "Free SO2."

Free SO2 exists in 3 forms and is the sum of Molecular SO2 (SO2), Bisulfite (HSO3-), and Sulfite (SO3=). Yair Margalit's Wine Concepts in Wine Chemistry 3rd edition explains how Free SO2 demonstrates itself, pages 315-319, http://www.amazon.com/Concepts-Wine-Technology-Operations-Edition/dp/1935879804. The graphic below shows the relative percentage of each form in a solution depending on its pH. In very acidic environments (pH near zero). Molecular SO2 dominates. As the pH rises, Bisulfite replaces Molecular SO2 until the pH reaches around 4.5 and Molecular SO2 vanishes. When the pH increases further, Bisulfate is increasingly replaced by Sulfite. Thus, wine having a pH between 3 and 4, Free SO2 is a mixture of mostly Bisulfite (HSO3-) and a small portion of molecular (SO2).

Here is what matters: The amount of Molecular SO2 in Free SO2 is relatively small in wine. For example: if you want to have 0.8 ppm of Molecular SO2, you need to provide 22 ppm of Free SO2 when the pH is 3.2; whereas you need 43 ppm of Free SO2 when the pH is 3.5. This is akin to breathing when you climb a very tall mountain: the higher you climb (in terms of pH), the more air you have to breathe to get your necessary oxygen (Molecular SO2). The problem is: wine with a pH above 3.65 requires too high a Sulfur addition. Thus one either depresses the pH by acidifying the wine or switches to an entirely different regime.

How much SO2 to add?

The accepted practice in the wine industry is to target a top Molecular SO2- level of around 0.5 – 0.7 ppm for red wine. The idea is to add as little SO2 as possible while preventing spoilage.

The upper bound is given by law (which sets a limit of 350 ppm Total SO2) and, more importantly, by sensory degradation: Total SO2 above 100 ppm can create a chemical taste that covers up fruitiness; Molecular SO2 above 0.7 ppm has a burnt match smell (sulfur).

The lower bound is given by the effectiveness of Molecular SO2 as an antioxidant and bacteria- and yeast-killer.

These boundaries create a challenge in wines with very low Acidity (high pH): the amount of Total SO2 to be added to create enough Molecular SO2 becomes too large. One response to this challenge is to increase the wine's Acidity artificially. Another is to be highly diligent with sanitation.

The compound most often used to add SO2 to wine is not SO2 itself but a powder, Potassium Metabisulfite K2S2O5, "KMBS," which contains 57.4% SO2. To calculate "A," the amount of KMBS (in grams) required, you need to know the following:

The volume of wine to be treated (gallons): V

The current level of "free SO2" in the wine (in ppm) – see measuring "free SO2": S

The pH level of the wine: p

The target level of "molecular SO2" (e.g., 0.5 ppm): M

The formula to calculate the estimated required amount of KMBS (in grams) (derived in Margalit's book) is:

A= 0.0065712 * V * [ M * (1+10(p-1.81)) – S ]

This formula approximates the balance between Bisulfite (HSO3-) and Molecular SO2 (SO2) in a liquid with a pH range between 1.5 and 4.5. The chart on the right shows the relationship. The constant 0.006572 = 3.785 / 1000 / 0.574 comes from converting gallons (3.785) into liters, ppm [i.e., mg/L into g/L (1000) and the fraction of Total SO2 in KMBS (57.4%). Note the two markers on the curve: The amount of Molecular SO2in Free SO2 is relatively small; i.e., the share of molecular SO2 is only 3.9% at a pH of 3.2, and it drops to 2% at a pH of 3.5. In other words, at normal pH levels in wine (between 3 and 4), we will see only a small amount of free and potentially active Molecular SO2.

So here are the guidelines we have followed for SO2 addition in practice:

In the years we use industrial yeasts for fermentation, we kill off all non-saccharomyces yeasts before cold soak or fermentation by adding an amount of KMBS, which creates a molecular SO2 level of 0.5 ppm. Since 2016 we have used the naturally occurring indigenous yeasts and no longer add any KMBS upfront.

While in the barrel, we measure the pH of the wine and the Free SO2 level every three months and compute the corresponding Molecular SO2 level. If Molecular SO2 has fallen below 0.35 ppm, we top up with KMBS to target a Molecular SO2 level of 0.45 ppm. This was the process we followed until 2019. In 2020 we stopped using SO2 in the cellar altogether. Having improved our sanitation significantly, we felt we could take the risk of no longer using SO2 as a preventative against contaminations.

Before bottling, we top up with KMBS to a target Molecular SO2 level of 0.5 ppm

Further Resouces: Good websites:

http://www.mbhes.com – distributor of SO2 measurement tools

http://www.practicalwinery.com/janfeb09/page5.htm - easy-to-read article

http://www.santarosa.edu/~jhenderson/Sulfur%20Dioxide.p°F – excellent lecture

http://fermsoft.com/sulphite.html - sulfite calculator from fermsoft.com

Measuring Free SO2

Unitil 2017, we measured Free SO2 by the "Aeration - Oxidation" method. First, the SO2 is removed by a stream of air passing through the sample solution, and the SO2 gas is trapped in a hydrogen peroxide solution which oxidizes it to sulfuric acid. Then the amount of sulfuric acid created is measured by titration with NaOH. The process takes four steps::

Step 1: Put the following into the round bubble flask (and close it)

10 milliliter of 25% Phosphoric Acid (use rubber ball at the end of pipette!)

20 milliliter of wine to be analyzed

Step 2: Fill the straight flask into which the vapor goes with

3% Hydrogen Peroxide up to the line and

Add three drops of green indicator solution (in the fridge)

Step 3: Set the pump timer to 10 minutes, turn on and put volume control so that the indicator shows midlevel volume. Wait till done. The liquid in the straight flask should turn purple

Step 4: Fill the titrator with 0.01 Sodium Hydroxide up to an easily identifiable Starting point

Put straight flask onto stirring table with stirrer inside and turn stirrer on

Slowly drip Sodium Hydroxide into purple liquid and stop when it turns green

Result: Free SO2 [in ppm] = (Start point [in milliliter] – Endpoint [in milliliter]) * 16

Note: a research paper posted in the November 2015 issue of Cornell University's Appellation Cornell Newsletter (http://grapesandwine.cals.cornell.edu/sites/grapesandwine.cals.cornell.edu/files/shared/Research%20Focus%202015-4.pdf ) argues that the above formula to calculate the amount A of required KMBS addition is approximative at best and tends to overestimate the needed addition. This is because the constant 1.81 (chemists call it the "pKa") used in the formula above depends on the alcohol content and the temperature of the wine. A pKa of 1.81 is correct for water; in wine, at 14% alcohol and 68 oF, the pKa is more like 1.95. The paper then suggests Headspace-Gas Detection, a new method to measure SO2 more accurately. For the time being, we will stick to the established industry practice described above.

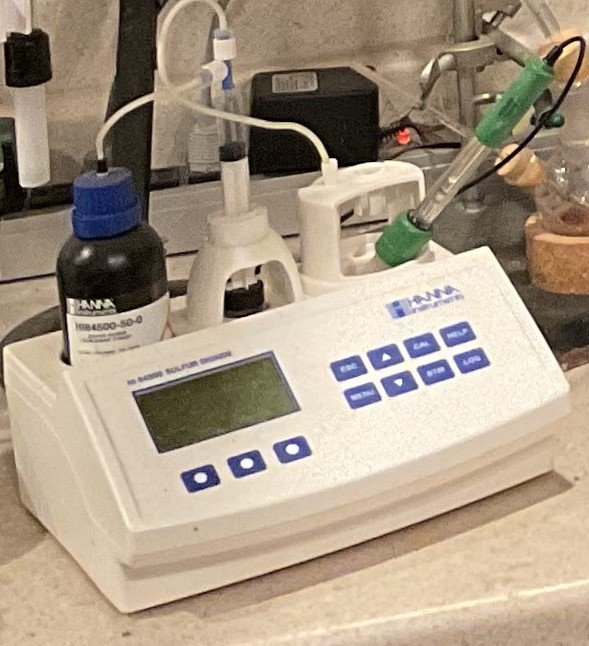

Since 2017, we have simplified the process using an automated titrator from Hanna Instruments. Since 2020 we hardly ever measure SO2 anymore as we use indigenous yeasts for fermentation, and we no longer rely on sulfur for sanitation.

Previous page: Accuro for ORP

Top of page: Go

Next Page: Measuring Dissolved Oxygen

Last updated: March 31 2023