Elevage

The term "Elevage" comes from French and, in this case, relates to maturing or growing up. We mature our wine in new and used ("neutral") French oak barrels for three years. The new oak imparts desirable flavors and allows the intake of a small amount of oxygen (around 8 mg O2 per Liter of wine per year, or about 3 g O2 per barrel per year). This combination helps polymerize tannins and anthocyanins and improves the quality of the wine.

Topping up

During elevage, the wine needs to be checked regularly for changes in chemical properties and possible infections by spoilage organisms (creating "wine faults"). Barrels also need to be topped-up regularly because wine evaporates through the wood staves. However, there is a trade-off between inspection frequency and the potential for spoilage. Each time we open a container, the wine gets exposed to oxygen and microbes in the air, with the potential for spoilage. Our goal is to inspect the wine and top up each barrel every 4-5 weeks. Our process has evolved:

From 2009 through 2016, we opened each barrel every 1-2 months and topped it up with wine from a shared top-up container. The disadvantage was that minor wine faults were carried forward from vintage to vintage. Over the years, we moved from topping up from steel tanks with floating tops and glass carboys to steel kegs pressurized with Argon.

Starting in 2017, we opened each barrel every 4-6 weeks and topped it up with wine from the same vintage. The disadvantage was that top-up wine had to be kept in a steel container without any exposure to oxygen for three years. To prevent topping up with sediments from the topup kegs, we installed floaters with flexible tubing inside the kegs so that the topup wine would come from the surface of the wine in the keg.

Starting in 2020, we dedicated a topup keg to each barrel and permanently connected it with a hose to its barrel; and each year, when we rack the barrel and the associated topup keg, we mix the contents. We top up every 4-5 weeks and extract a sample for inspection by a permanently installed tube. The advantages are 1) we only open the barrel once a year, and 2) wine in the topup keg remains without any oxygen for only one year. The disadvantage is that we can only make adjustments to the wine once a year. The picture shows the setup.

Inspection

After we extract a sample from each cellar batch (barrel or topup keg), we rate the wine for looks, nose, and taste, and we run it through our spectral analyzers for the following properties:

Malic and Lactic acids: If we are looking for progress in malolactic fermentation, malic acids should decline from an initial level of around 1,500 ppm to zero, compensated by an equal increase in lactic acids.

Acidity: We measure pH and Total Acidity (TA). Our target ranges are 3.35 to 3.55 for pH and 5,000 to 7,000 ppm for TA.

Volatile Acidity VA: VA is primarily acetic acid (vinegar), a byproduct of bacterial spoilage. We monitor VA attentively; it generally rises from 300 to 800 ppm during elevage. When it rises fast or exceeds 900 ppm, we get concerned about spoilage and initiate fining and filtering.

Alcohol and Density. We target alcohol to be in the 13% to 13.5% range. Density is usually around 0.9920.

Fructose and Glucose. Sugars are a sign of incomplete fermentation. Acceptable ranges are 0 to 800 ppm total for both.

Anthocyanins. We measure total, free and bound anthocyanins. Bound anthocyanins are anthocyanins linked to tannins – they give red wine the color and textural and sensory qualities. We hope for bound anthocyanins above 200 ppm in Cabernet Sauvignon.

Tannins. Tannins are astringent and precipitate proteins – that is why tannic red wine pairs well with fatty foods. We look for tannins in the 800 to 1,600 ppm range

Total IRPs. Total Iron-Reactive Phenols represent to amount of all phenolic compounds in the wine. We look for Total IRPs in the above 1,400 ppm

We cannot measure Free SO2 with our spectral analyzers. Free SO2 is the amount of SO2 that effectively prevents microbial growth in the wine. Conventional wisdom suggests one should add SO2 when the level of Free SO2 falls below ten ppm. We have changed our strategy over the last few years and eliminated SO2 additions, except right before bottling.

The following chart shows all the measurements taken on all cellar batches for every vintage. Note that many of the measures outside the targeted ranges are from topup batches that we do not actively manage.

Deciding on adjustments

Since 2017 we have run all the tests every time we topup a barrel on each involved cellar batch, i.e., vessel. The critical adjustments are driven by:

Monitoring the progress of the malolactic fermentation

Monitoring and, if necessary, adjusting acidity

Detecting and correcting wine faults. We monitor increases in Volatile Acidity, which are an excellent early indicator. As described below, we rely on our noses and tastebuds to identify wine faults. We make adjustments by fining and filtering.

Timing of racking barrels (every year), blending cellar batches, and bottling.

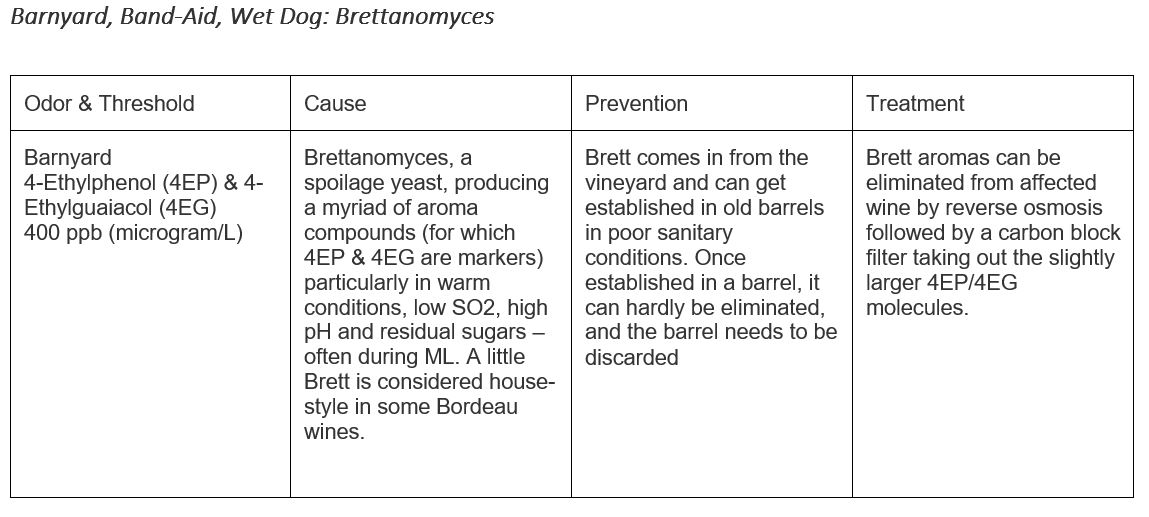

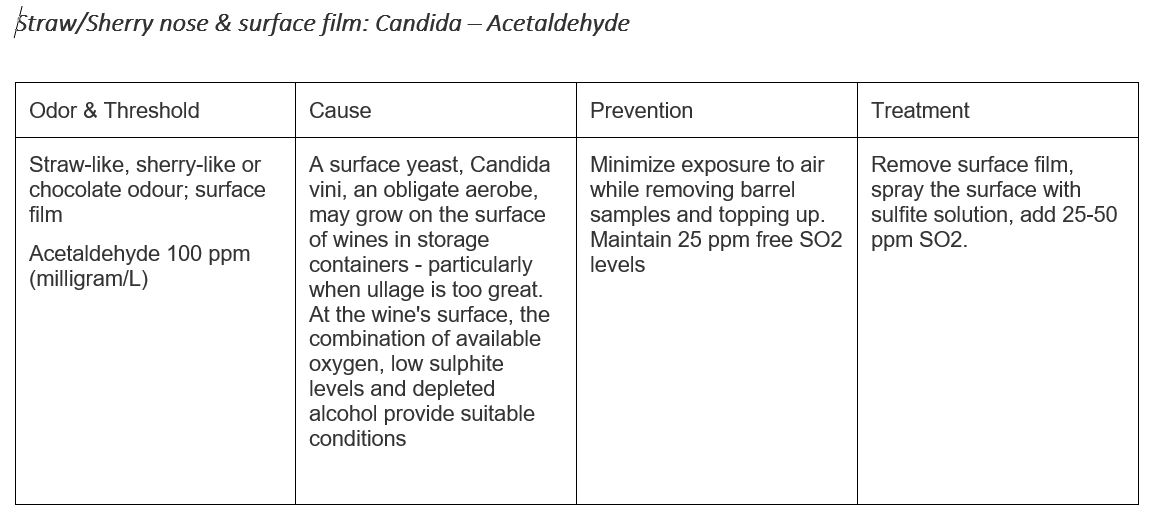

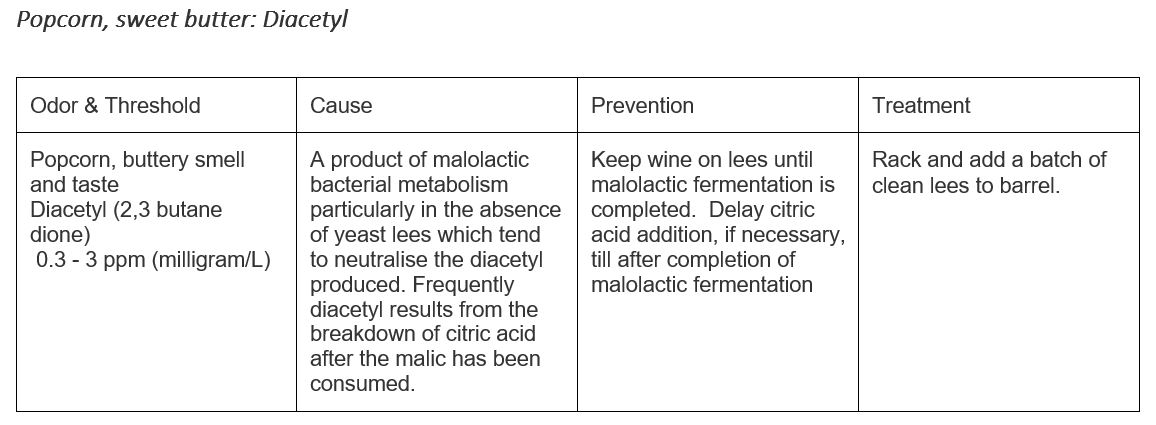

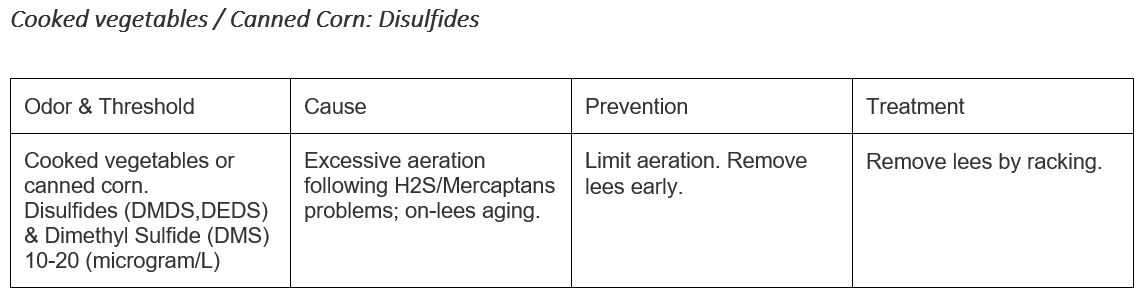

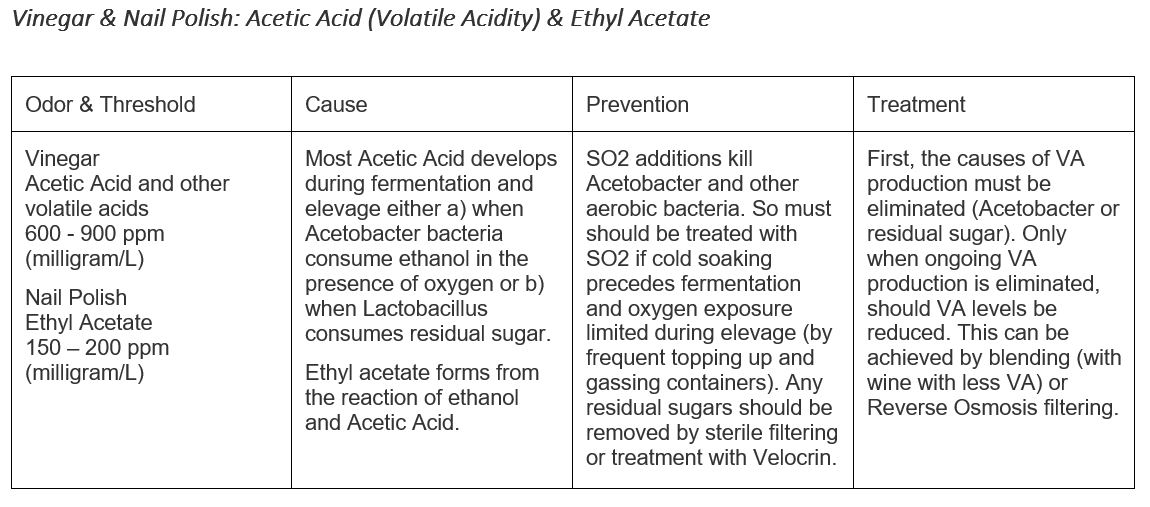

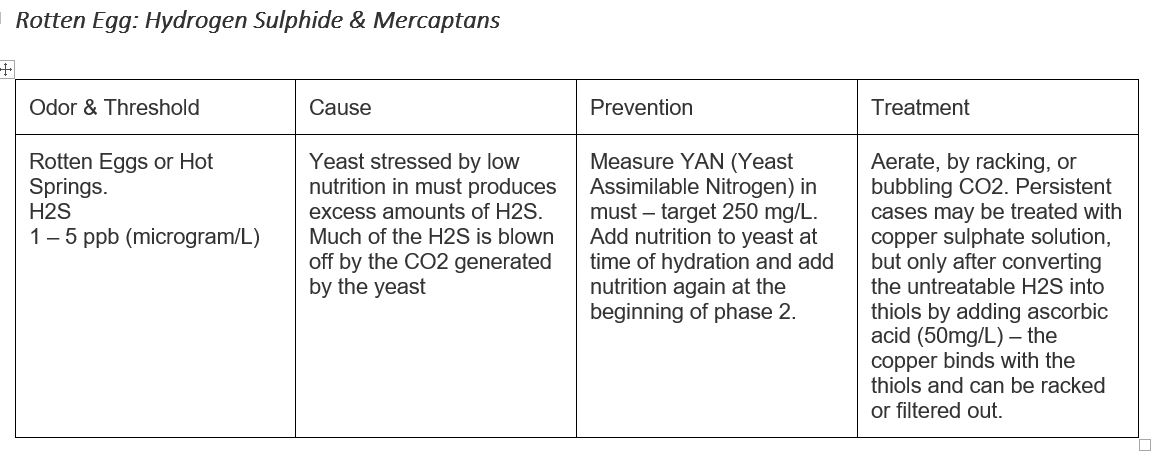

The following pages describe the adjustments in more detail. A trained nose can identify the off-smell of contaminated wine. The tables were adapted from an ETS Laboratories' Winemakers' Quarterly (see www.ETSLabs.com), from the British Columbia Winemakers Association website www..bcawa.ca/winemaking/flaws.htm, and Enotools website www.enotools.com/wine-faults--whats-wrong-with-my-wine.html. They summarise key off-odors and tastes, the chemical compound responsible for them, their indicative sensory threshold, the most probable origin of the problem, how it can be prevented, and possible corrections. Treatment should always be preceded by first eliminating the original cause. All treatments with chemical additions are problematic and should be done in stages or on samples first.

Topping up

Oak barrels need to be topped up regularly because a small amount of wine (called "angels' share") evaporates through the staves. The evaporation rate is usually around 3-4% p.a., depending on the humidity in the cellar. Wine components inside the barrel migrate through the wood at various speeds and evaporate from the outside surface. Assuming the migration rates of the liquid components (say 87% water and 13% alcohol) depend mainly on the differences in concentrations between the inside and outside of the barrel, the alcohol concentration in the wine changes. We keep the cellar at around 60% humidity, so the concentration differences are 27% for water and 13% for alcohol (assuming the alcohol in the cellar air is zero). Therefore at 60% cellar humidity, water leaves the barrel twice as fast as alcohol, and an assumed 3% annual evaporation consists of approximately 93% water and 7% alcohol. If you start the year with 100L wine at 13% alcohol, you end with 87-3%*93 = 84.2L of water and 13-3%*7 = 12.89L of alcohol, and the new alcohol concentration in the remaining 97.09L of wine is 12.89 / 97.09 = 13.27%, an increase of 0.27%. This calculation illustrates why barrel cellars should be kept humid.

On the other hand, whatever wine evaporates from the barrel is replaced by air sucked into the barrel by the resulting loss of volume and vacuum. The atmosphere consists of roughly 20% oxygen and 80% nitrogen. Nitrogen is nearly inert and has no influence on the wine; oxygen does. At a very low continuous rate, oxygen has a very beneficial impact on the development of the wine; too much is detrimental. Thus, oak barrels with a beneficial transmission rate are an excellent vessel for maturing wine. When wine is matured in steel tanks, minuscule amounts of oxygen need to be injected (micro-oxygenation)

Our method of topping up has evolved significantly over the years. We started by simply removing the barrel bung, taking samples, filling the barrel back up from a shared topup tank, and putting the bung back in. The problem was contamination from the topup tank or the “dirty” air in the cellar contacting the wine while the barrel was open. The picture on the right shows the current setup. A topup tank is dedicated to each barrel and contains the same wine. A steel tank with Argon provides pressure. The topup tank links to the barrel with a plastic hose through the bung. The bung has entries for two more hoses with valves at the ends. One is to extract sample wine; the other is to let the air out of the barrel when it is topped up. When topping up is complete, we disconnect the hose leading to the barrel from the topup tank.

Data Management

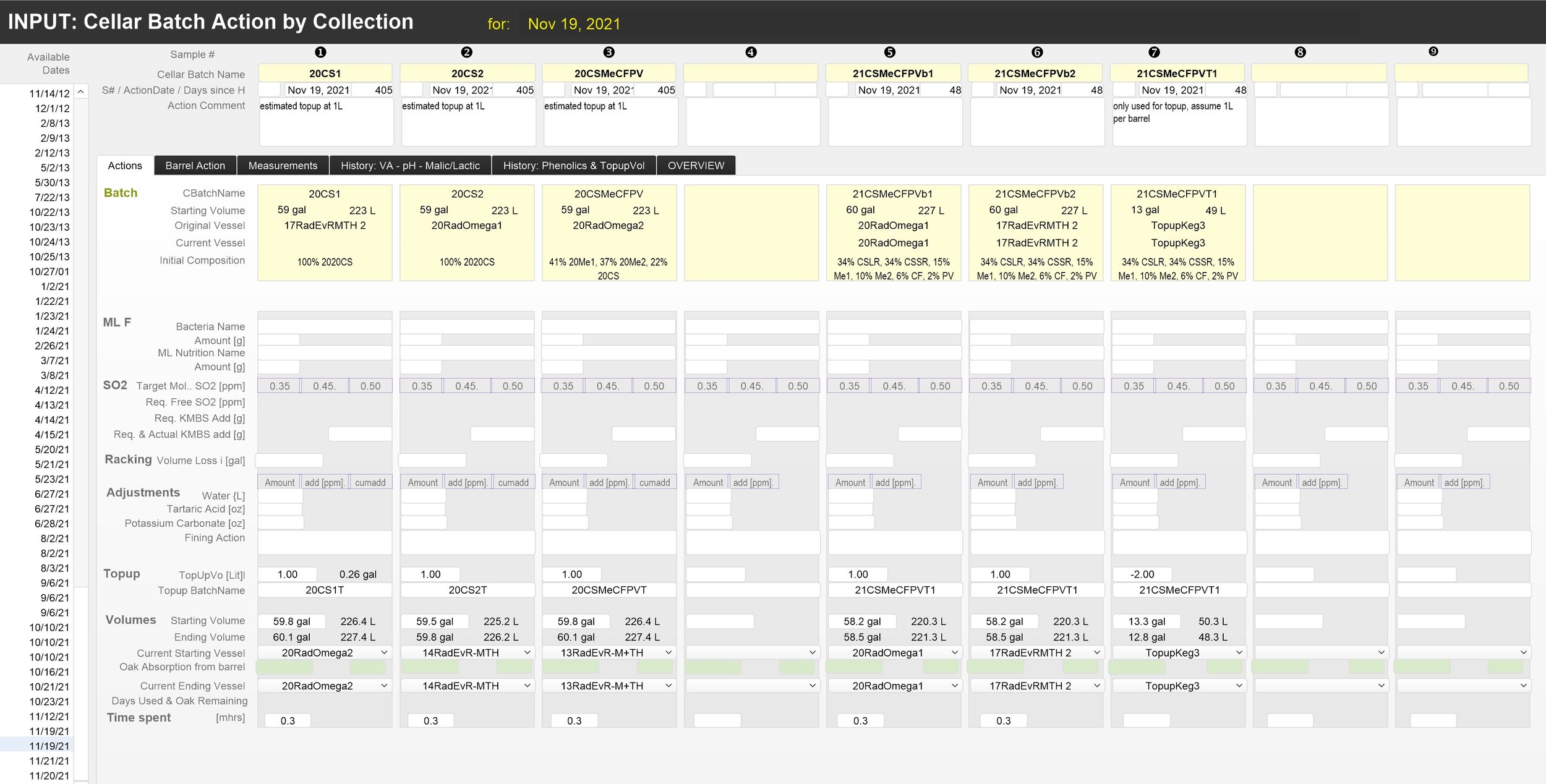

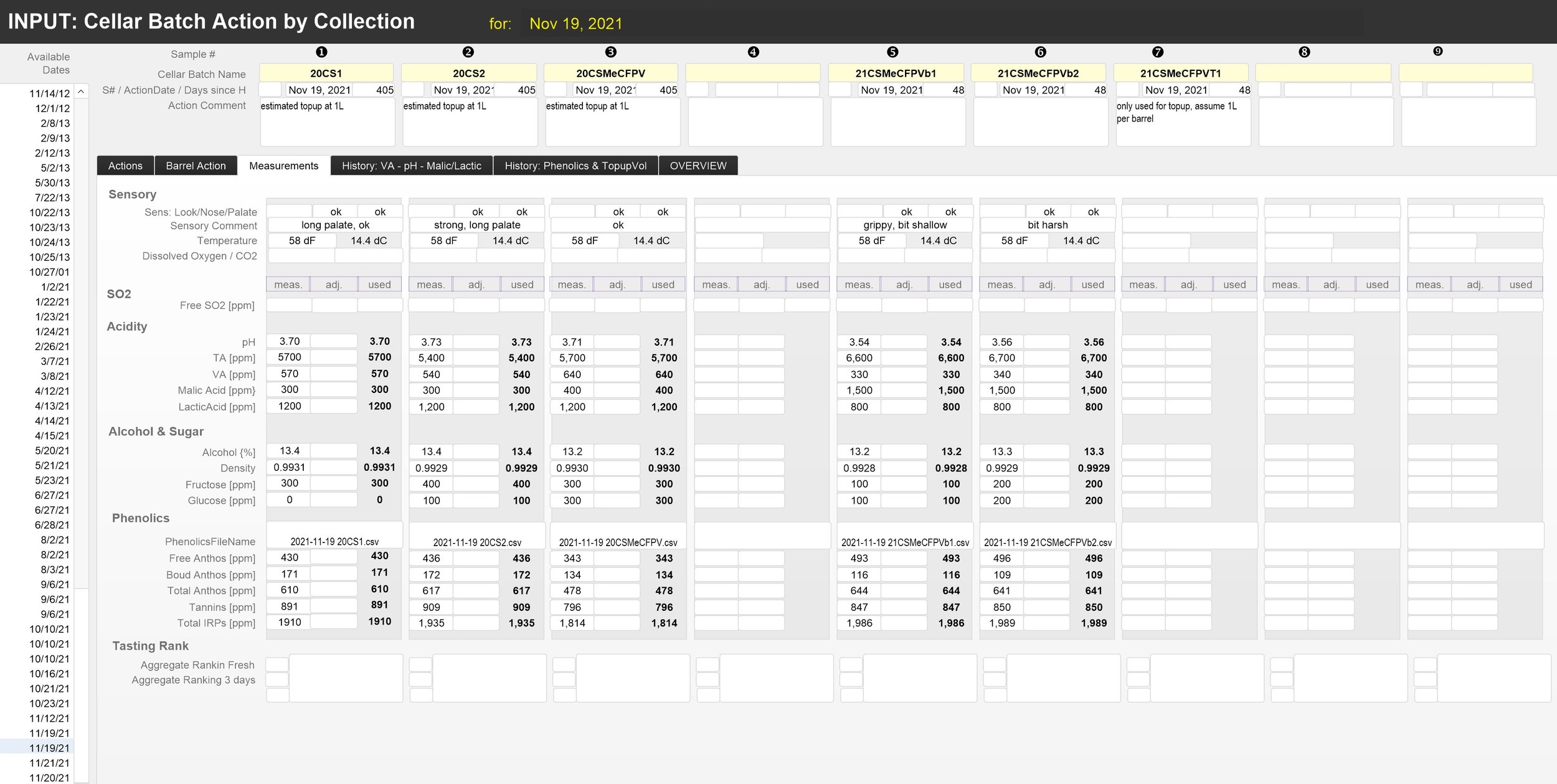

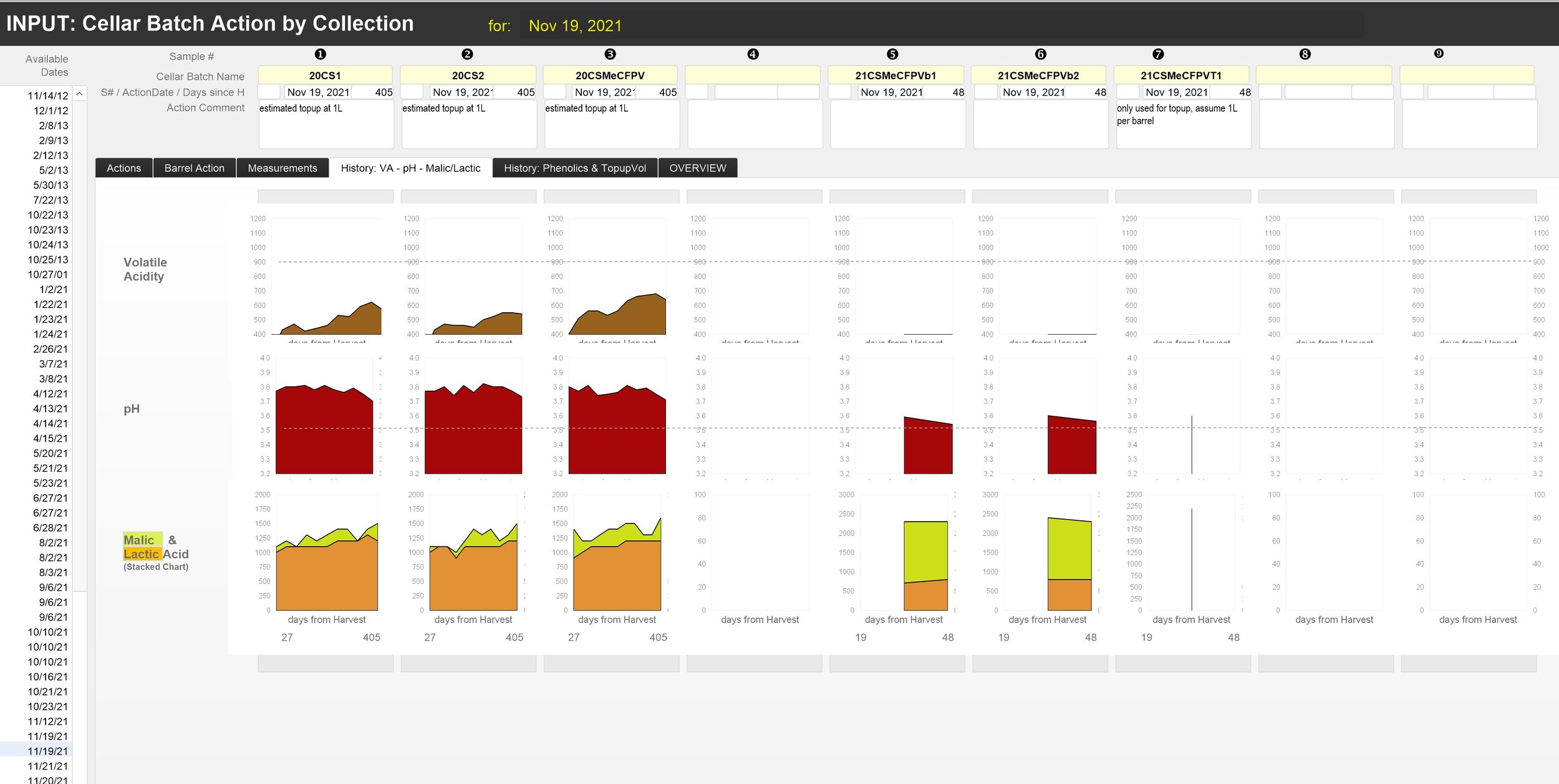

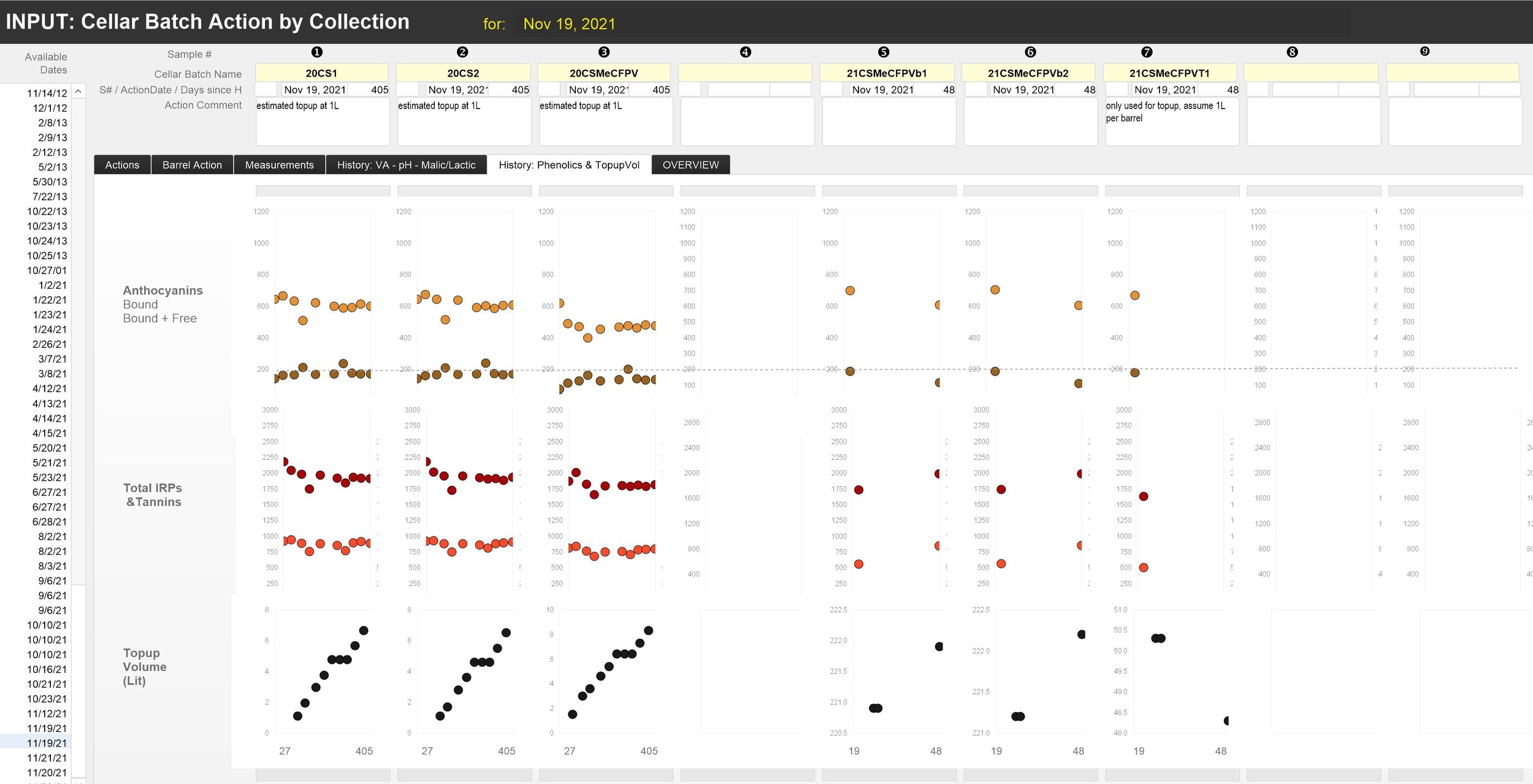

We manage the elevage for cellar batches of the same vintage together. The following four screenshots of the layout INPUT: Cellarbatch Actions by Collections of November 21, 2021, shows the input for the topup of the 2020 and 2021 vintages

The Actions tab shows the amount of the topup

The Measurements tab shows the measurements taken

The History VA… shows the acidity measurements in the context of past measurements

The History Phenolics tab shows the history of the phenolics measurement and topup volumes

Last year: elevage during 2021

In 2021 we completed the elevage of the 2018 vintage, continued the elevage of the 2019 & 2020 vintages, and started the elevage of the 2021 vintage. The screenshot of the COMPARE: Vintages layout shows how they fared compared to previous ones. The first screenshot shows the summary for the vintages; the second shows the actions and measurements during elevage.

2018 turns out to be one of the better vintages: Phenolic content was high, second only to the record-setting 2013 vintage. Acidity was acceptable and required only a minor addition of tartaric acids. However, as the screenshot of the REVIEW Vintage 2018 – Elevage shows, in the barrels, Volatile Acidity rose early to a relatively high level, warranting fining with StabMicro

Previous page: Tank & Barrel Management

Top of page: Go

Next page: Malolactic Fermentation

Last updated: May 25, 2022