Tank & Barrel Management

We cellar the wine in stainless steel tanks and oak barrels:

Steel tanks and steel barrels for mixing and transferring wine are easy to clean and maintain, and they last forever.

French Oak barrels for maturing wine. Up to 3-4 years old, oak barrels add desirable flavors and tannins to the wine. After four years, they are called neutral. The advantage of oak barrels is that they breathe: they allow very slow oxidation from the air that enters through the wood staves. As air enters, liquids evaporate through the wood. Consequently, the barrels need to be topped up every 4-5 weeks. A similar effect can be achieved in steel tanks by inserting oak staves or chips and injecting oxygen at an extremely slow and controlled rate (micro-oxidation).

Speciality steel kegs for keeping odd lots and top-up wine are easy to clean and come in various sizes. They have a mechanism to inject inert gas.

We currently don't use micro-oxidation systems (too expensive), so all maturation is done in oak barrels or steel kegs.

Economics of oak barrels

For large wineries, stainless steel tanks are hands-down the most economical solution because they come in enormous sizes and are easy to clean and maintain. Only commercial wineries which can charge over $40 retail per bottle tend to use new oak barrels. A new 60-gallon oak barrel costs between $600 (American and East European varieties) and $1200 (French varieties). They add desirable flavors to the wine for 3-4 years; after that, they are called neutral and trade for $150-$300 in the secondary market. Neutral barrels, when properly maintained, can last for over a decade. New 60-gallon stainless steel barrels cost $500-700 and last forever. So, using new French oak barrels for every vintage would cost around $20/gallon or $3.50/bottle. Our average incremental cost for using French barrels is around $1/bottle of wine as we increasingly use neutral barrels.

We keep track of how many days we have exposed each oak barrel to each maturing wine batch to calculate how much "oak flavor" is left before they become neutral.

Choosing Oak Barrels

Barrel makers have the fanciest booths at trade shows and spend the most on brand marketing. That is because the characteristics of barrels are hard to measure and much depends on individual taste and image. On top of the difficulty of quantifying qualities, research studies indicate that characteristics of the same type of barrels from the same manufacturer vary widely.

We buy up to two new barrels every 2 to 3 years. Consequently, we have no opportunity to test a wide range. So we decided, somewhat arbitrarily, to concentrate on buying our barrels from Radoux, one of the large, well-regarded French "Tonneliers." We tried a couple of barrels from Seguin Moreau but found them to impart too intense flavors. American oak, as compared to French oak, imparts different flavors and has a slightly higher oxygen transfer rate (see the page on Elevage). As these comments indicate, we conservatively buy from an established large supplier – not much analysis or research is involved here.

Choosing Stainless Steel Tanks, Barrels & Kegs

Stainless steel containers are made to individual specifications by specialty manufacturers or bought from catalogs according to standard sizes and specifications. We are using four types of stainless steel containers in the cellar:

Mixing and settling tanks hold the contents of multiple barrels for mixing or for settling out suspended particles. We shield the wine from oxygen by a "heavier than air" inert gas floating blanket. We use Argon preferably, and in less critical situations, Nitrogen or CO2. These tanks have large openings on the top and the side for easy cleaning. We use a round stationary 200-gallon tank (made to order by Santa Rosa Stainless Steel, http://srss.com/) and a square 180-gallon tank (purchased from Metalcraft, https://custom-metalcraft.com/winery-tanks-equipment/ ) that we can raise with a hydraulic forklift.

Storage & transfer barrels with a capacity of 30 or 60 gallons are used to hold wine while cleaning a barrel. We bought our 30 & 60-gallon steel transfer barrels from Metalcraft (https://custom-metalcraft.com/shop/accessories/stainless-steel-wine-barrels/).

Variable top tanks are designed to hold varying amounts of wine. Their top floats on the surface of the wine and is sealed with an inflatable gasket to prevent exposure to air. We use them for small batch fermentations and, in the past, to hold odd amounts of young wine set aside for topping-up barrels. We bought our 100 & 200-liter variable-top tanks from Fermentation Solutions (no longer in business).

Pressurized kegs are designed to hold variable amounts of wine (5-gallon Corny Kegs or 15-gallon KegMenters) under the slight pressure of an inert gas (e.g., Argon). We use them to hold young wine set aside for topping up barrels. We bought Kegland Kegmenters with a floating pickup ball from Williams Brewing (https://www.williamsbrewing.com/Home-Brewing-Equipment/Kegging-Equipment/Kegs/132-Gallon-Kegland-Kegmenter ) and MoreWine (www.morebeer.com).

All of our tanks and barrels are on dollies so they can be moved around easily, and they are designed to be lifted (by hoists or forklifts) to move the contents by gravity instead of pumps.

Barrel Maintenance

Barrels need proper maintenance. They must be adequately humidified to tighten up before first use, they must be cleaned regularly of sediments and wine spoilage organisms, and they must be stored properly when not full of wine.

Cleaning is about removing sediments settling primarily on the floor of the barrel and about killing wine spoilage microorganisms (bacteria and fungi, mostly hiding in crevices and inside near the top of the barrel). There are for primary methods of cleaning:

Water: Spraying the inside of barrels with cold or warm/hot water under high pressure is the most common method of washing out crud and sediments, but it is not very effective in removing spoilage microorganisms from deep crevices in the staves.

Steam: Steaming barrels with pressurized, super-saturated water is very effective. We steam the barrel for 4 minutes, then bung it for 4 minutes to let the steam cool down and create a vacuum that extracts deep-seated spoilage organisms. Then we rinse the barrel out with water. Care must be taken to limit the cool-down period; otherwise, the barrel implodes.

Sulfur Dioxide: Burning a pure elemental sulfur wick inside the barrel effectively keeps dry barrels sanitized during storage. As an alternative, barrels can be washed out with a weak solution of KMBS (potassium metabisulfite dissolved in water creates molecular SO2).

Ozone: Fumigating the inside of a barrel with Ozone molecules (O3) is very useful in killing harmful microorganisms (bacteria, fungi, and biofilms). It requires an ozone generator and with a diffuser.

All cleaning water used inside a barrel should first be stripped of chlorine and contaminants found in regular drinking water

What we do when

We built a barrel washer that holds water in a basin and circulates it with a high-pressure pump through a rotating spray valve inside the barrel. The barrel sits on top so it can be rotated to insert the steaming wand of a steam generator. The barrel washer also holds an electric ozone generator with a timer (Model MP-8000 from A2Z Ozone, https://www.a2zozone.com/products/mp-8000-multi-purpose-ozone-generator). Here is our current barrel maintenance practice::

Initialization: Before using any new barrel, we fill it with filtered warm water and let the staves soak up and tighten. This takes a few days. Then the barrel is rinsed out with the barrel washer, steamed, let cool down for a day, and then filled with new wine.

Regular cleaning between uses. We pressure-wash the barrel and rinse it three times on our barrel washer. Then, twice, we steam it, let the steam cool down to create a vacuum, and rinse the extracted debris with cold water. For the steaming, we use a Swash Portable Steam Generator (https://www.swashequipment.com/steam-generators-n ). Then we allow the barrel to cool down and dry for a day before fumigating it for 2 hours with Ozone. Then the barrel is ready for a refill.

Storing used barrels: if a barrel is put in storage, we burn a sulfur pill inside and close the barrel with a bung so the trapped SO2 prevents the growth of new microorganisms. The burning tablet is held in the center of the barrel in a small stainless steel basket suspended from the bunghole. If barrel storage is extended, the burning is repeated every 4-6 months. Before a barrel is reused, it is cleaned and steamed inside with the barrel washer (see above) and outside with a steam power washer used to clean the steel tanks and other equipment.

The pictures show the barrel washer, the steam pressure washer and the sulfur pill holder.

Data Management

Because a barrel's ability to impart oak flavors to wine declines over time, tracking which barrel is used for how long with which cellar batch is essential. We assume that an oak barrel has a half-life of 1.25 years, i.e., in 450 days of continuous exposure to wine, it loses 50% of its original ability to flavor the wine.

This screenshot shows the usage of the 2011 Radoux barrel. The column Remaining Oak shows how the oak depletion progressed over ten years of intermittent use for multiple cellar batches, reaching 2% in November 2021.

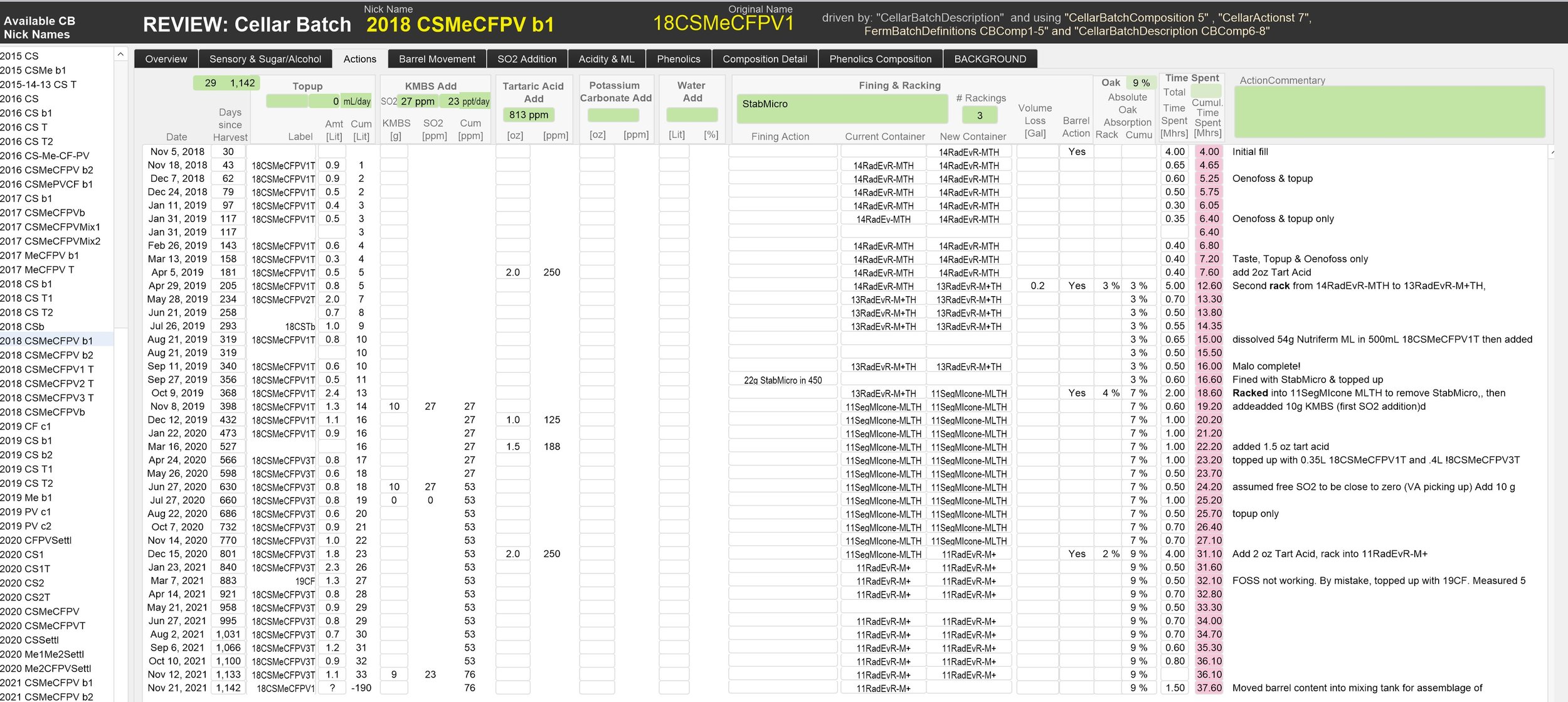

The following two screenshots are from the REVIEW Cellerbatch layout for the 2018 Bordeau Blend barrel 1, 18CSMeCFPV1. The first shows all the actions. Note, the cumulative oak absorption over three years in the cellar was only 9%, i.e., this cellar batch was exposed to very little oak flavoring – a deliberate decision given its phenolic profile

The second shows details on when we moved the batch from one barrel to the next.