Fermentation Batch Review (steps 3-17)

Data Management

To review each Fermentation Batch, we designed a layout that pulls all berry tests and fermentation actions data together. The goal is to provide a context to explain the actions taken and the results achieved in a uniform format across all fermentations all vintages. The “REVIEW: Fermentation Batch” layout has seven tabs:

MUF Calibration: is used to review the calibration and adjustments made to the OenoFoss “Must-Under-Fermentation” measurements

Phenolics: is used to correct the results from WineXRay’s phenolic component estimates, which tend to show aberrations due to sampling errors in the spectral analysis

Acidity: is used to review the different measurements of acidity and comment on the effect of acidity adjustments

Actions: This is used to review and comment on all actions taken during fermentation

Fermentation: This is used to review and comment on the progress of the fermentation

Source Detail: This is used to review and comment on the quality of harvest blocks which make up a fermentation batch

Overview: sums up all the commentaries and data in the previous six tabs.

In the following paragraphs, we show the screenshots for each tab using the actual data for the 2017CSLR1 fermentation batch

MUF Calibration tab

This tab shows the OenoFoss measurements of the chemical properties and the adjusted values. An adjustment has to be made to the raw “MUF / MustUnderFermentation”-measurement because OenoFoss only provides calibrated measurements for “Must” and for “Finished Wine.” Note, we need to input the boundary conditions in this table for the adjustments to happen. An explanation of how the adjustment is calculated can be found in the Laboratory section.

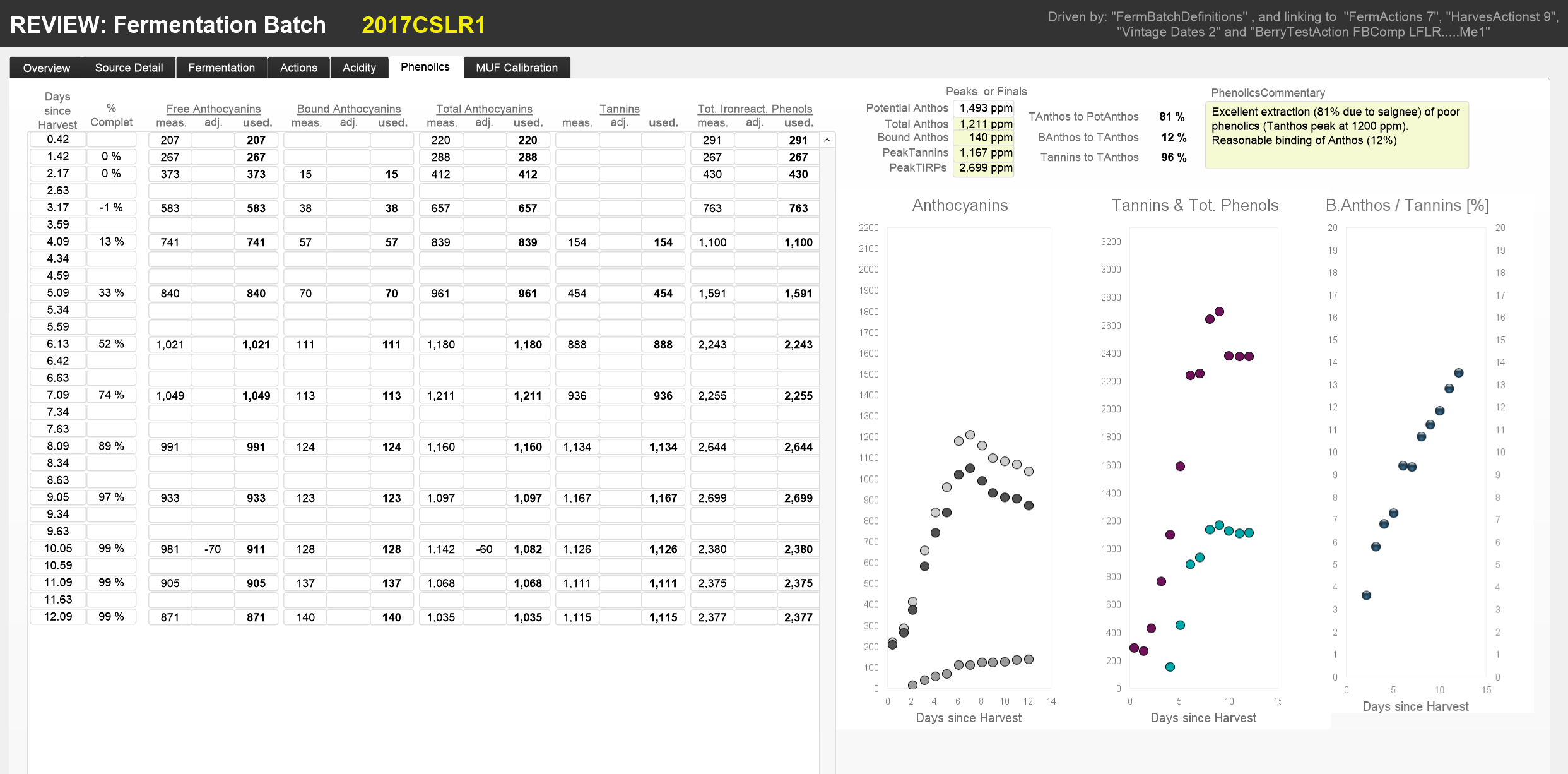

Phenolics tab

The Phenolics tab reviews the phenolic results provided by WineXray based on the measured spectrum of each sample. Impurities occasionally distort the measured spectra in the sample. As a consequence, the phenolic results are distorted. We use this layout to make manual adjustments to the phenolic results by inspecting the graphs and eliminating outliers. Again, we input the yellow fields during the review to summarise the results.

Acidity tab

The Acidity tab shows the evolution of the OenoFoss-based measurements of pH, TA, VA, Tartaric Acid, Gluconic Acid, and Malic Acid, and the timing of the Tartaric Acid additions, if any. Note, the table shows the adjusted values described in the MUF-Calibration tab. We complete the yellow fields during the review to summarise the results.

Actions tab

The Actions tab reviews the actions taken during winemaking. The steps include saignee, additions of water, enzymes, yeasts, nutrition, sulfur, oxygen, tartaric acid oak chips, and the removal of skins and seeds in pressing. This tab allows reconciling the batch weights throughout all steps. Again, we enter summary data in the yellow fields during the review process.

Fermentations tab

The Fermentations tab reviews the progress of the fermentation in terms of fermentation step and conversion of sugars to alcohol as measured by completion %, Brix, density, glucose, fructose, and alcohol. This tab also lists all the action comments. Again, we enter summary data in the yellow fields during the review process.

Source Detail tab

This tab shows the berry test results of the components making up the fermentation batch. In this instance, the 2017CSLR1 batch consisted of only one component, grapes from the CSLR block. In other instances, we would see multiple rows of graphs in this layout – one for each component.

Overview tab

The Overview tab pulls together all the information added in the yellow fields in the previously discussed tabs. The goal of the fermentation batch review is the write a Batch Commentary that summarises all the information collected.

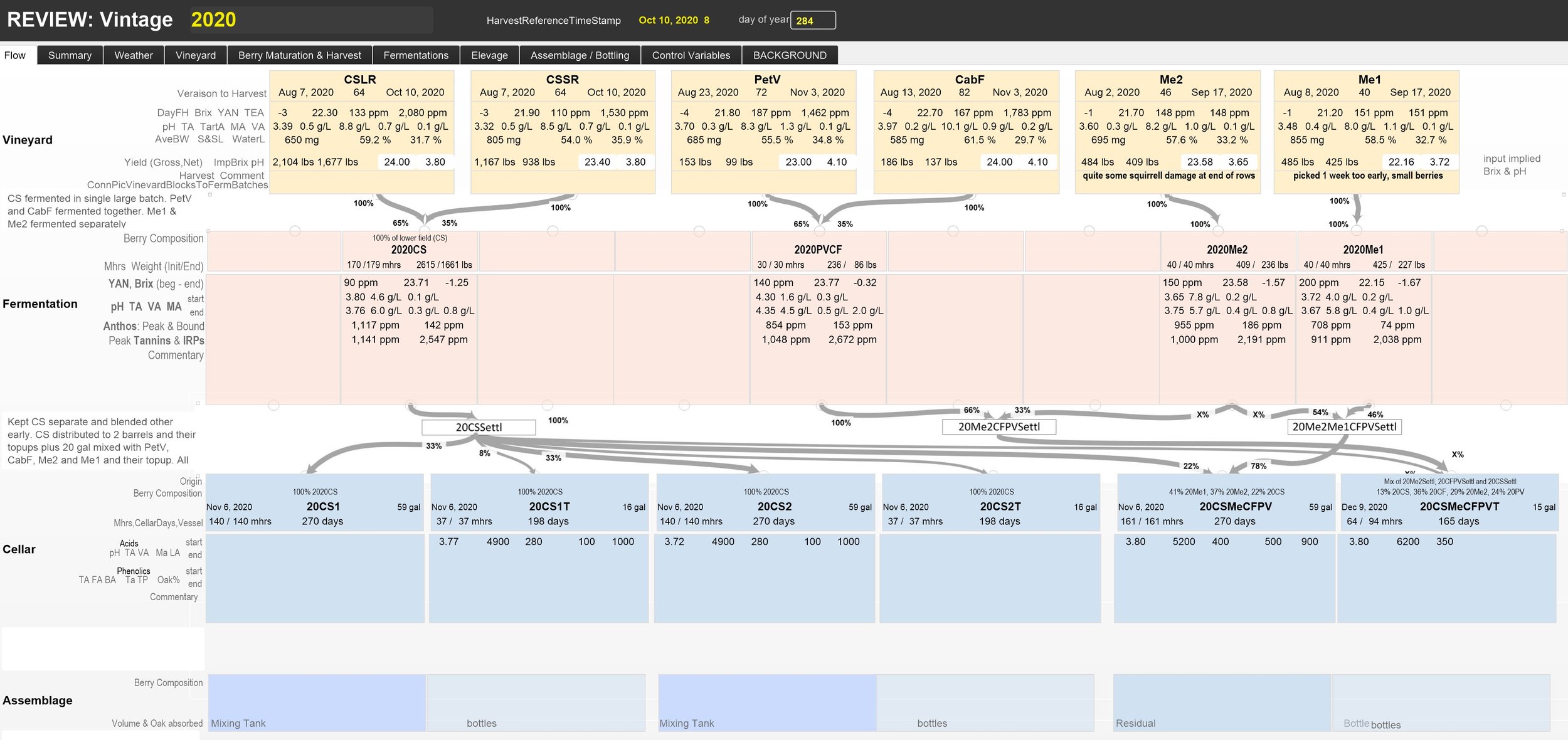

Tracking Results for 2020

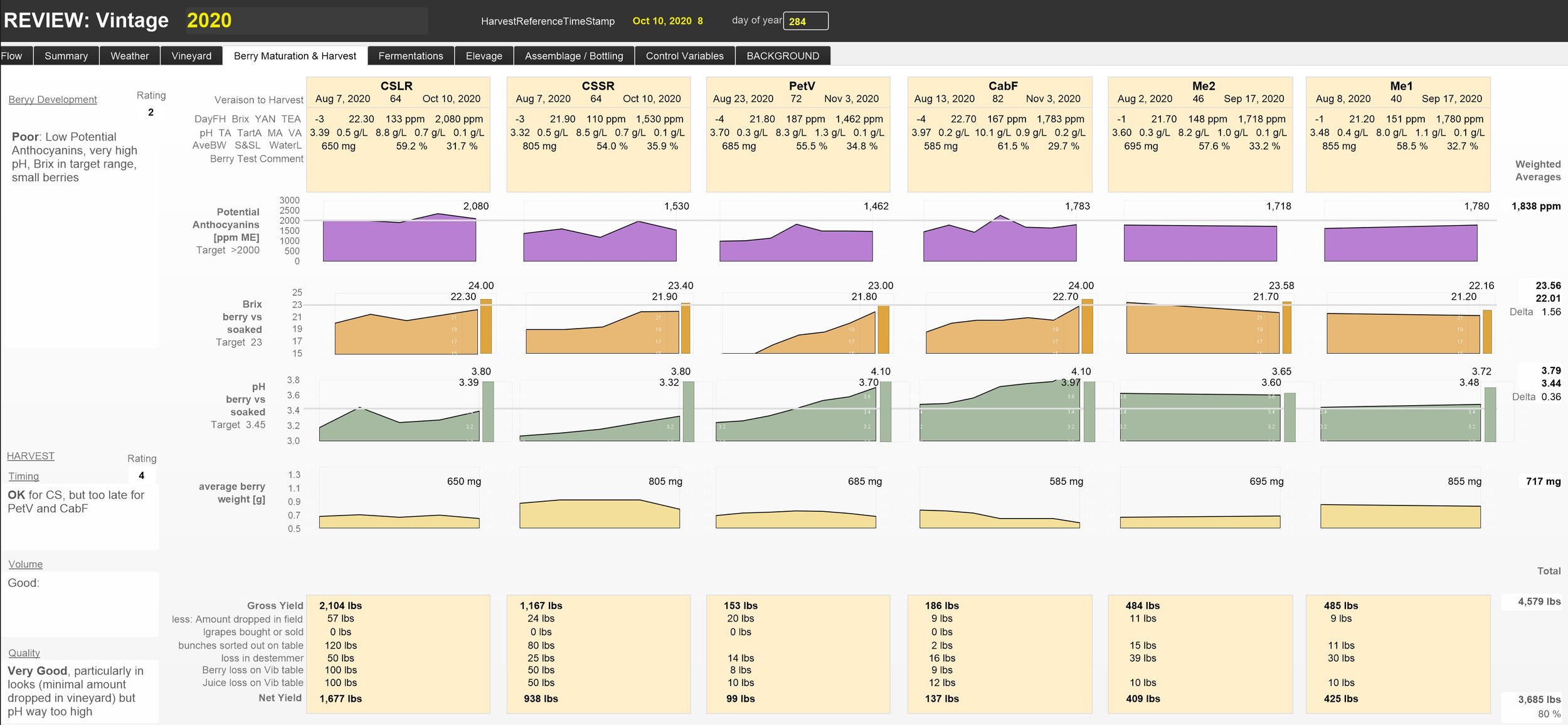

Currently, the “REVIEW: Vintage” layout provides the best overview of what we did with the 2020 vintage. We described it already on the Winery Overview page. Note, in 2020, we defined separate Settlement Batches to mix different fermentations and let them settle. The following three screenshots show

the flows from harvest blocks through fermentations to settlement

more detail on the berry maturation and harvest conditions

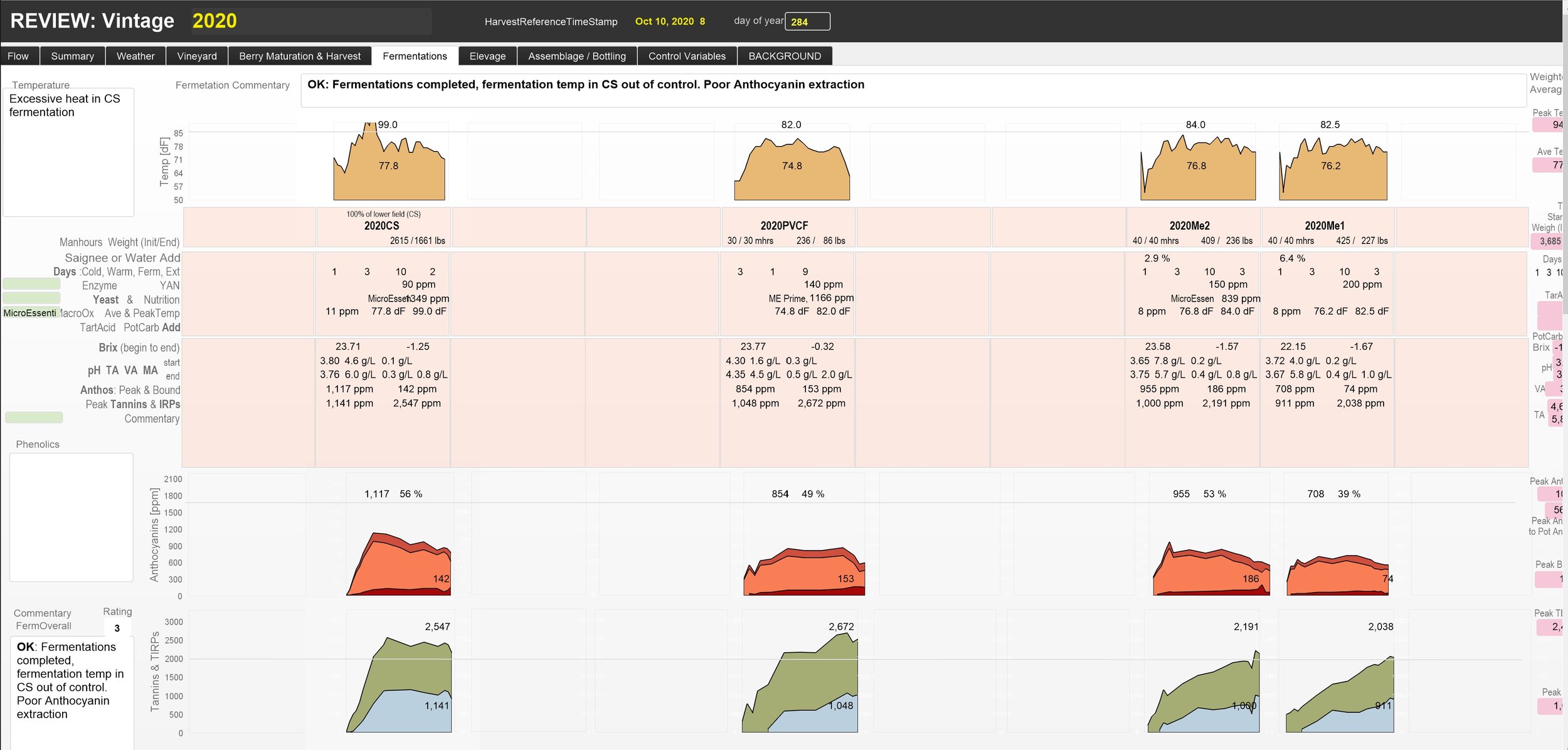

comparative data on the different ferments

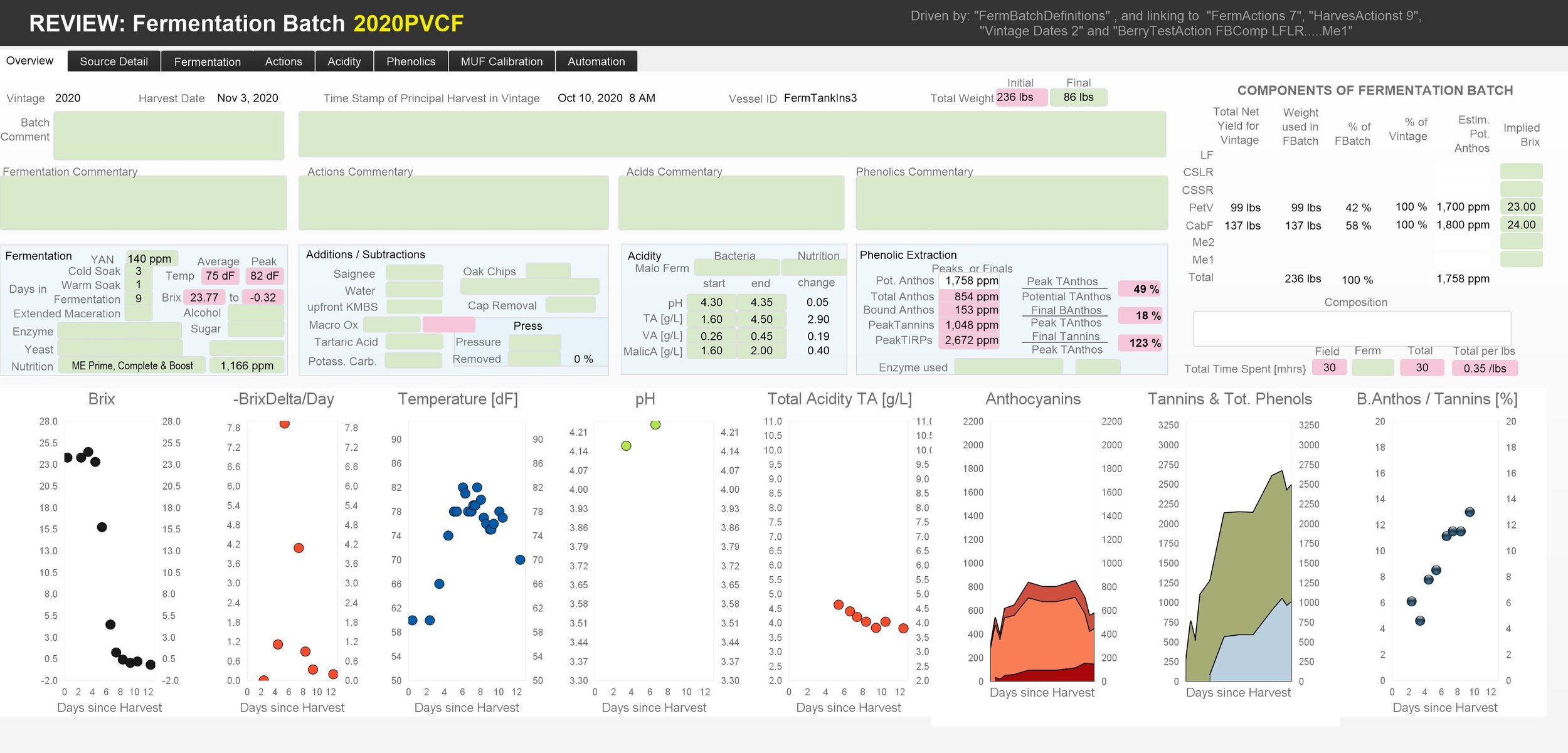

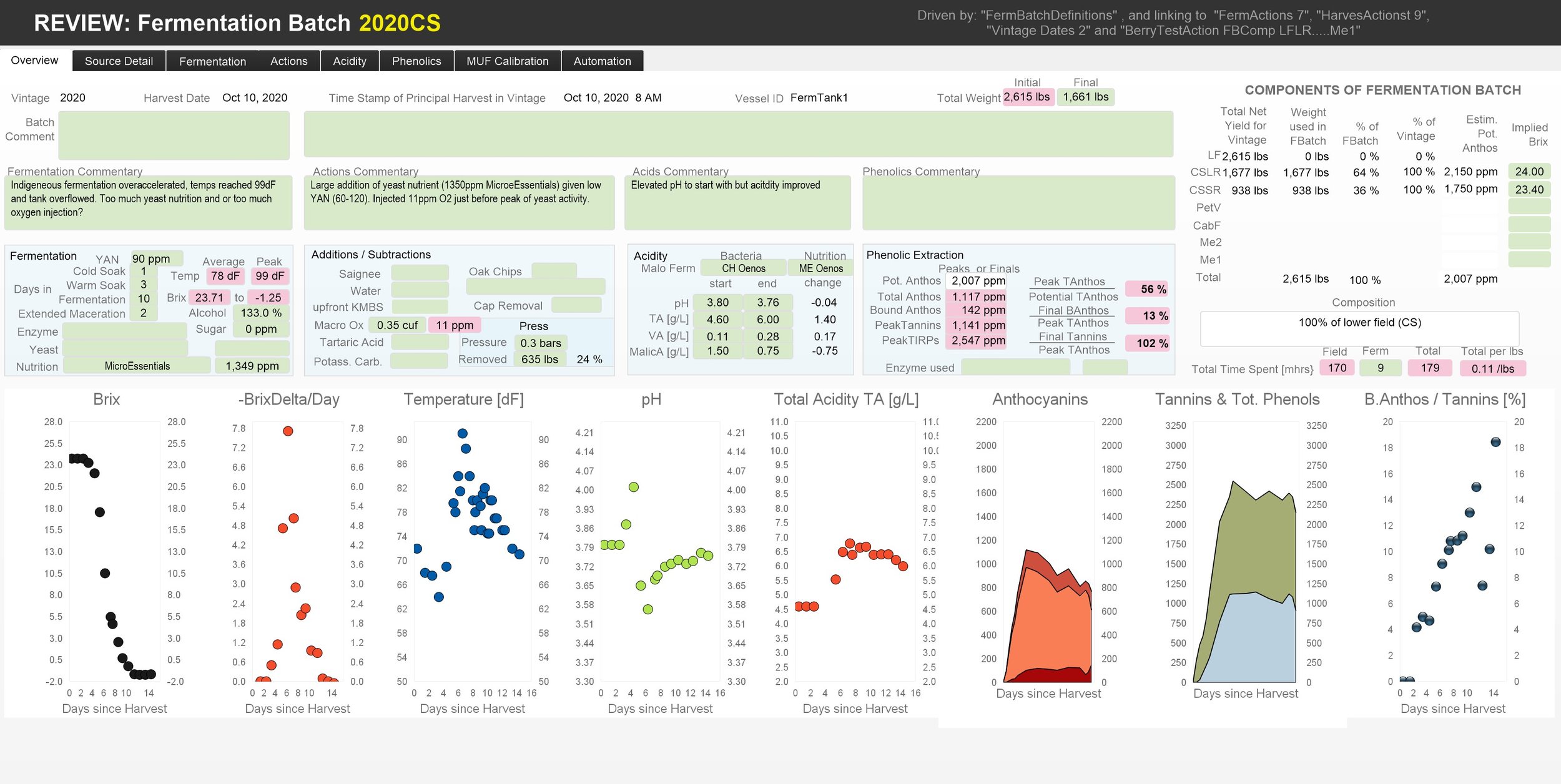

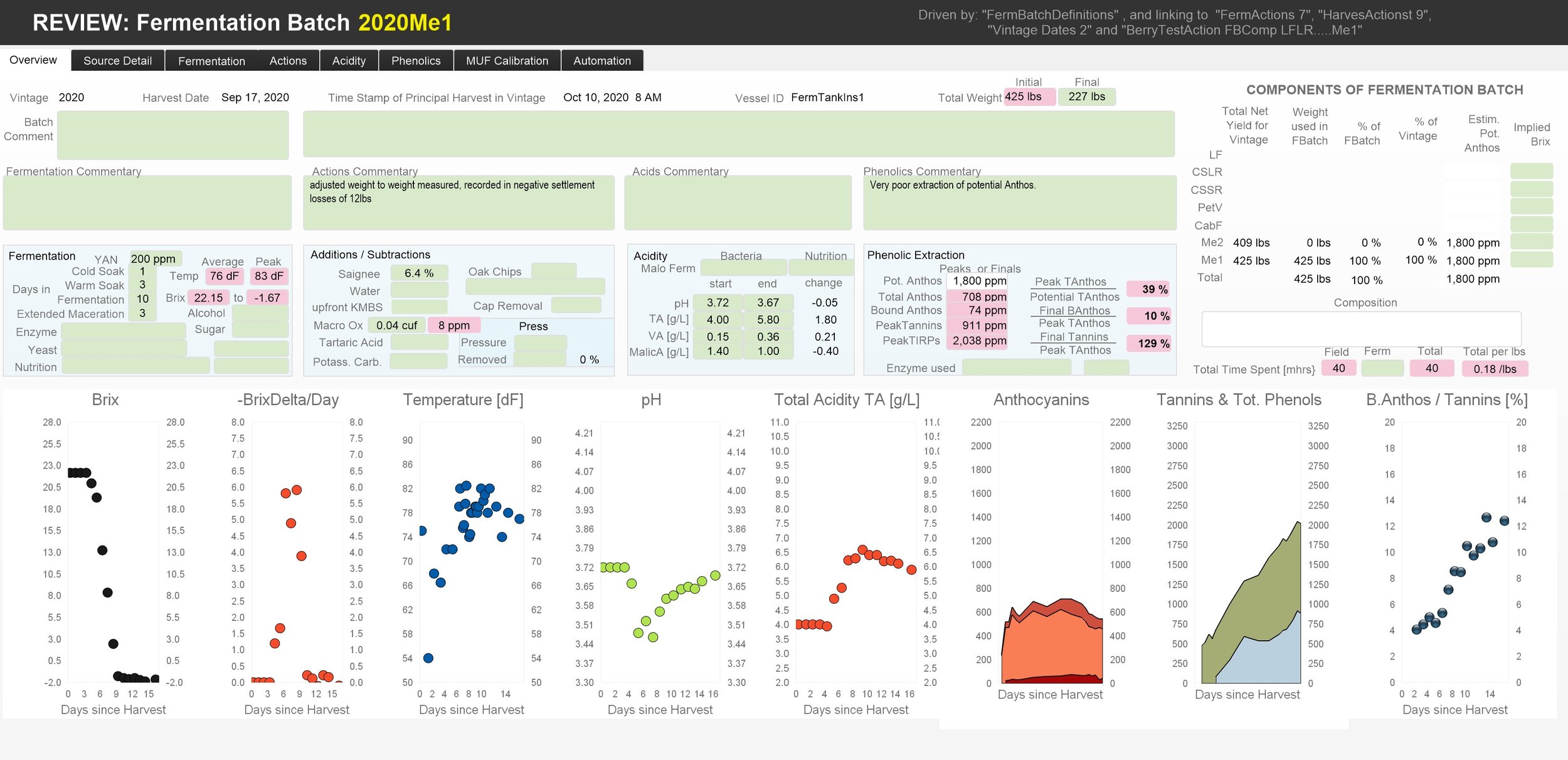

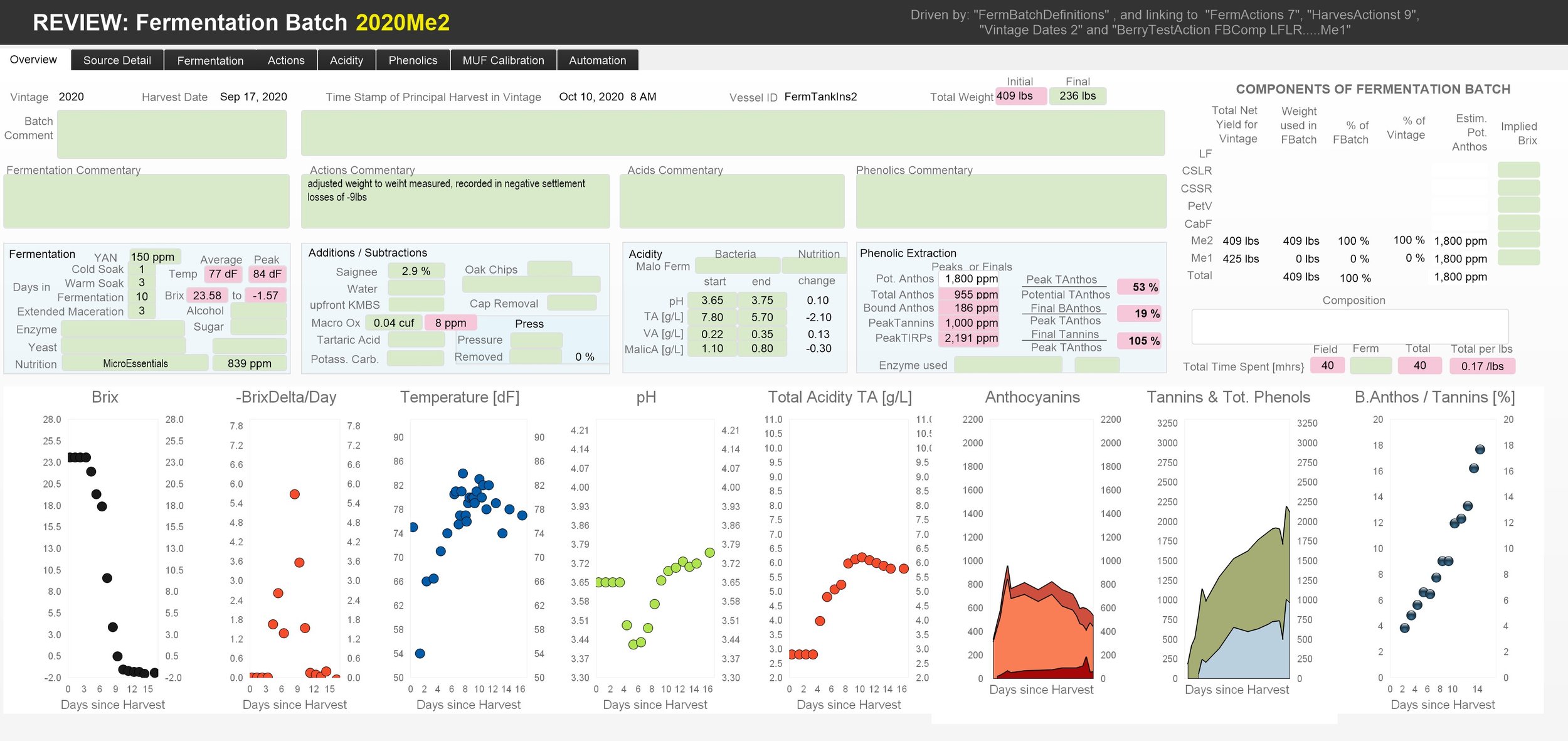

The following screenshots show the Overview tab of the “REVIEW: Fermentation Batch” layout for each of the 4 fermentations, all indigenous. Note

the temperature peak in the CS fermentation

the similarity of the two Merlot fermentations, and

the very high pH in the CFPV ferment.

In each of these layouts, the commentaries have not yet been written

On completion of all fermentations, we settled the CS in one large tank, and we combined the Me1, Me2, and CFPV fermentations in two separate settlement tanks. From there, we created three cellar batches, two CS and once CS-Me-CF-PV mix, each consisting of a full barrel and dedicated topup tank.

Previous page: Step #14-19: Extended Maceration to Press

Top of Page: Go

Next Page: Cellar OVERVIEW

Last updated: November 28, 2021